24

Before Use

Prepare measuring device

● Clean connection of the compressed gas supply (blow out with oil-

free and grease-free air).

● Clean the measuring device. It must be free of particles and dust.

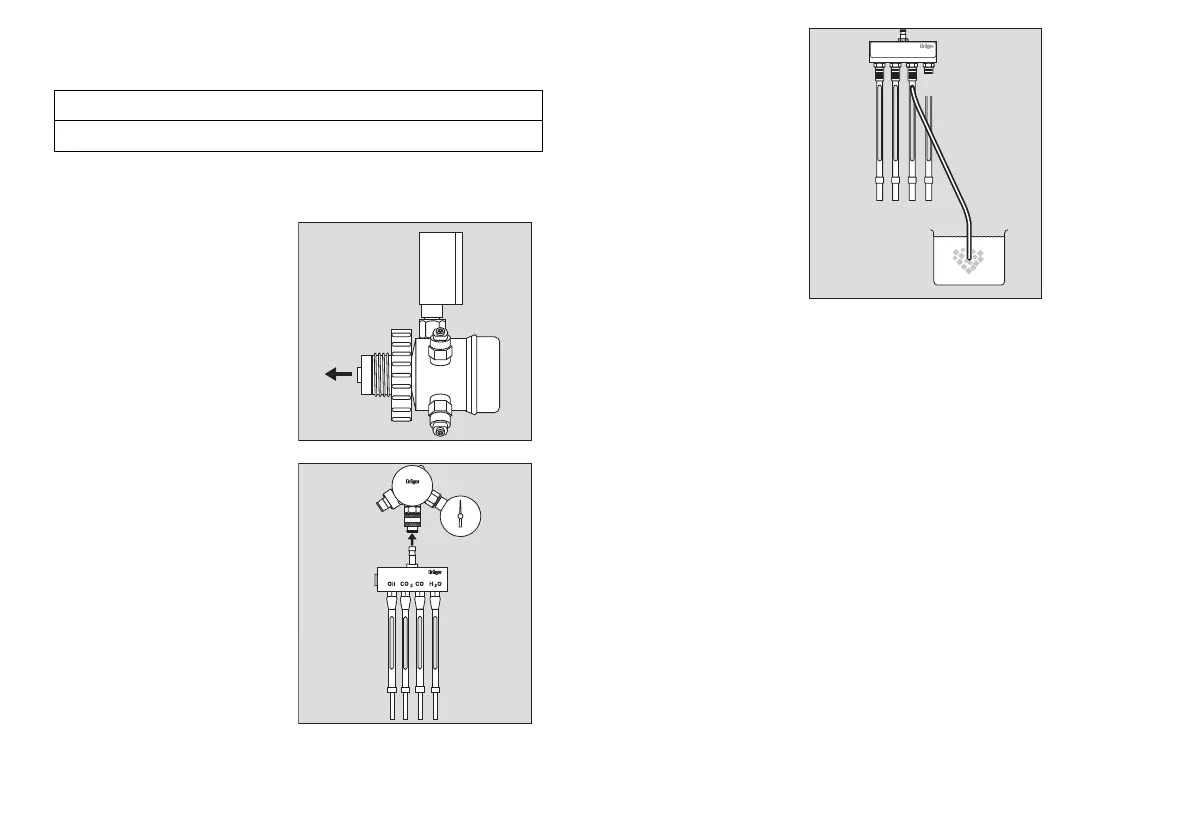

● Unscrew the protective cap

and connect the pressure

reducer with the connection

of the compressed gas

supply (1). Do not use a tool

for pressure reducers. Only

use your hands to make the

connection. If necessary,

use adapters: see “Technical

data” on page 35.

● Connect the measuring

device (2) to the pressure

reducer (plug connection).

High pressure system:

● The pressure reducer is

preconfigured to 8.5 bars.

Low pressure system:

● In cases of alternating

primary pressures from 3 to

15 bars, the pressure point

(3 bars) must be readjusted

on the pressure reducer's

handwheel. Check the

pressure gauge setting.

NOTICE

Only use a device if it is clean.

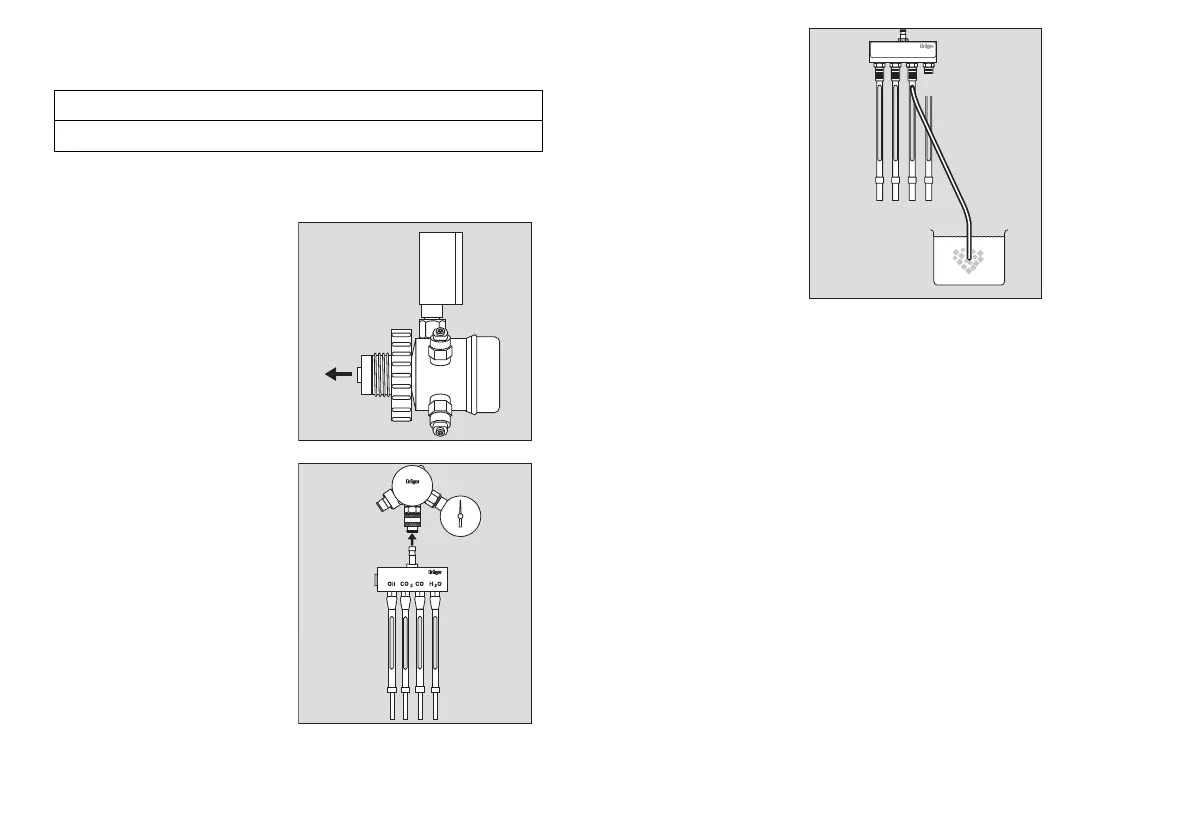

● Insert the bubble test hose in

the corresponding test

connection (3) of the

measuring device.

● Dip the other end of the

bubble test hose (4) in a

container full of water.

● Slowly open the compressed

gas supply valve and clean

the compressed gas system

(disperse compressed gas).

In case of regularly

maintained systems:

2 to 3 minutes.

For other systems:

5 to 6 minutes.

● Count the rising bubbles:

Severe build up of bubbles on CO

2

, CO, nitrous gases, H

2

S and SO

2

test connection. In case of little or no bubble build up, clean the

device, see “Cleaning” on page 32.

Severe build up of bubbles (uncountable) on oil and H

2

O test

connection. In case of little or no bubble build up: clean the device,

see “Cleaning” on page 32.

●Close valve.

01021765.eps

Oil CO

2

CO H

2

O

3

4

Loading...

Loading...