Fault Finding Guide

31

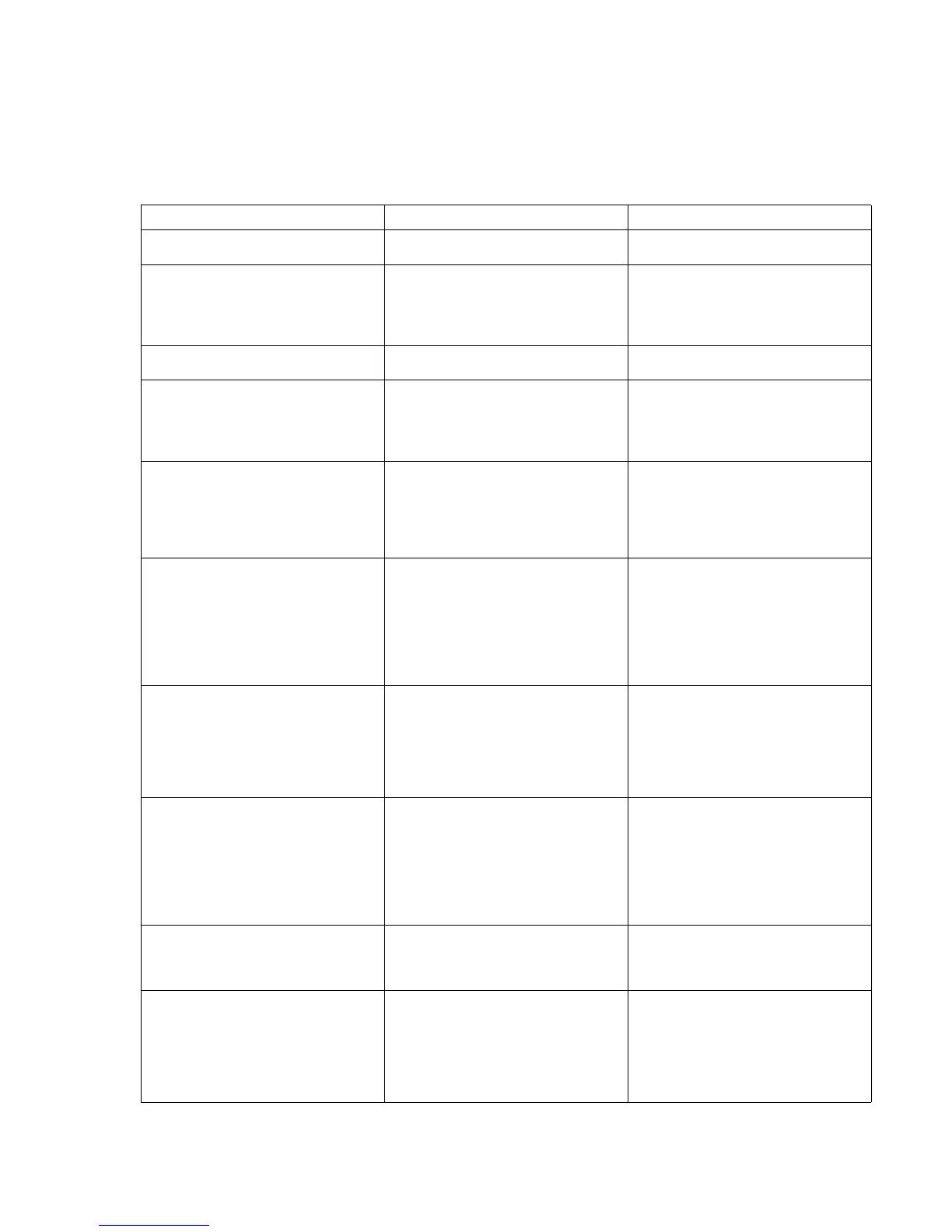

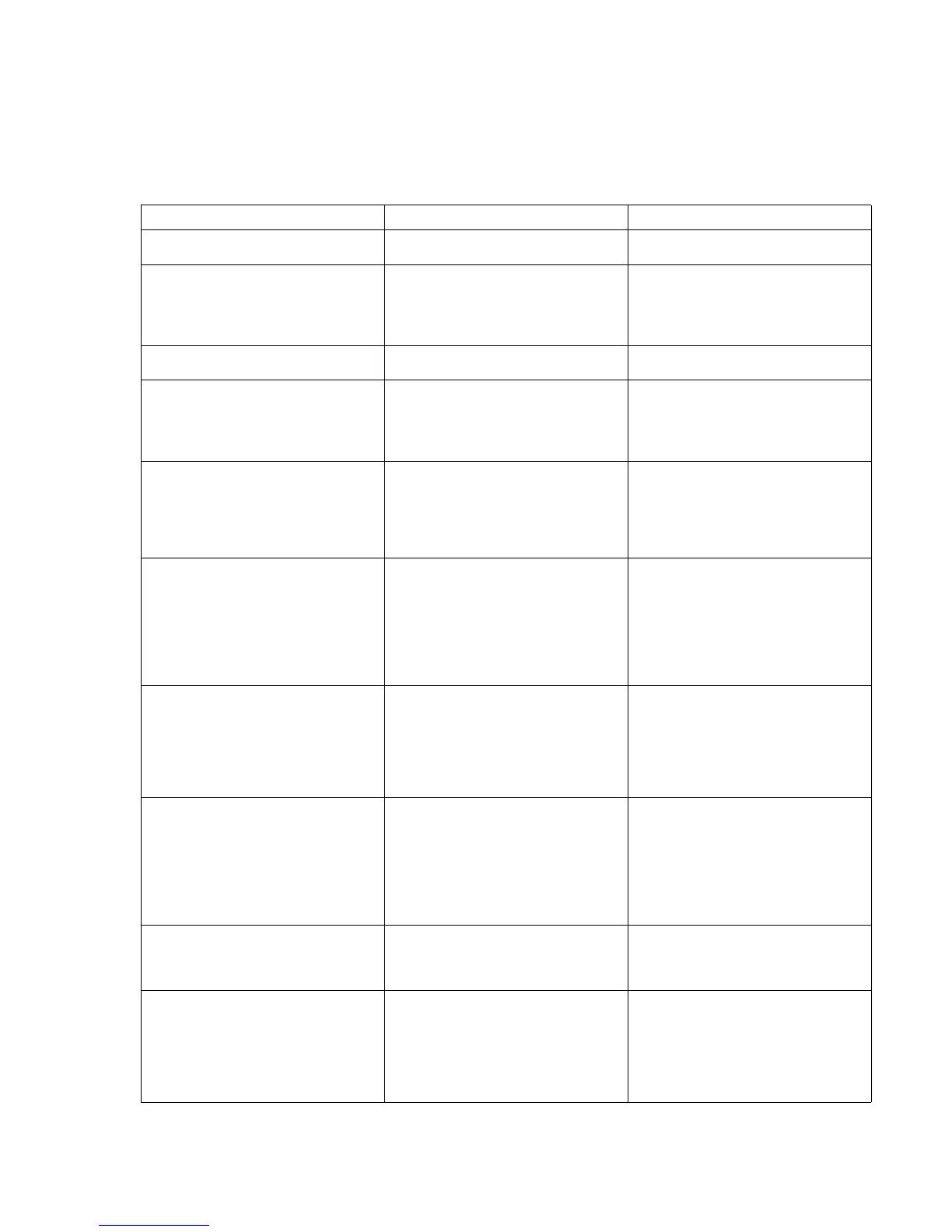

Problems relating to the Receiver.

Symptoms Cause Action

The detector output is at Fault (<1mA). The

HHT receives no data

The Receiver is not powered Check the power supply and cabling

The Receiver has an internal fault Remove the Receiver head and gimbal

assembly from its mounting, replace it with a

spare with the same configuration, and

return it to the factory. Realign and re-zero

the detector in the normal way

The detector output is at full scale (20mA) The self-zeroing sequence has not been

completed

Align and zero the detector in the normal

way

The detector fails to complete the self-zero-

ing sequence. The HHT shows the Optics

flag is set.

An internal check has detected abnormally

high signal strength. This is normally due to

the Attenuator Plate not being fitted

Measure the distance between the Transmit-

ter and the Receiver. The Attenuator Plate

must be fitted if the distance is below 16

metres. The central cut-out must be removed

if the distance is between 8 and 16 metres

The detector fails to complete the self-zero-

ing sequence. The HHT shows flags indicat-

ing Transmitter and/or Receiver

misalignment, even though no flags were set

in normal operation

The tests for correct alignment are made

more stringent during the self-zeroing proce-

dure. This is to give the detector the best

chance of working reliably, allowing for small

movements in the supporting structure over

a period of time

Check that both the Transmitter and

Receiver are rigidly mounted. Carefully

repeat the alignment procedure, ensuring

that both the Transmitter and Receiver are

aligned at the centre of the strong central

peak. Restart the self-zeroing procedure

The detector output is at Pre warning. The

HHT shows the Optics flag is set

The signal strength has remained for some

time significantly below the signal recorded

when the detector was last zeroed. The mar-

gin of signal loss, and the interval for which

it must be maintained, to generate the warn-

ing are both part of the Receiver configura-

tion. Typical values are 40% loss for more

than four days

Check the lenses of Transmitter and

Receiver are clean. If necessary, clean, rea-

lign and rezero the detector. In some loca-

tions fog may persist for longer than the

chosen interval, causing the warning to be

generated. It may then be ignored, or a

longer interval entered

The detector behaves erratically. It changes

unpredictably from normal operation with

the HHT showing a strong signal to a Beam-

block and little or no signal although the

path is not obstructed. The HHT continues

to receive data at the normal rate even when

power is removed from the Transmitter

The Receiver is seeing light from more than

one Transmitter on the same Channel

Ensure that Receivers of all detectors within

sight of each other are configured to sepa-

rate Channels, and that each Transmitter is

configured to the same Channel as its own

Receiver

The detector output is at Beam-block. The

HHT shows the 'RxAlign' flag is set, even

though it was not set before the Beam-block

occurred

The optical tests which detect misalignment

of the Receiver also serve to prevent its giv-

ing false gas readings due to a partial

obstruction of the beam. If a partial obstruc-

tion capable of causing a false alarm per-

sists for longer than the Beam-block delay it

will cause a Beam-block that is indicated like

this

Check for causes of partial obstruction such

as a vehicle, a crane or a build-up of snow or

ice intruding into the beam path

The Receiver has become sufficiently mis-

aligned to cause a Beam-block in a time too

short for the warning to be generated

Investigate the cause of the movement. The

Receiver may have been struck or the sup-

porting structure may not be sufficiently

rigid

We have installed several detectors with

similar configurations. One shows a lower

response to the plastic test sheets than the

others

The inbuilt calibration is for the specified

gas, not for solid plastic. The sheets are

intended to demonstrate that the detector is

working correctly, not to simulate any partic-

ular quantity of gas. It is normal for individual

units to show widely differing responses to

the sheets

If required, the gas response can be tested

directly and in situ using the gas cells sup-

plied in the GCK400 kit

Loading...

Loading...