24

XT SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

Steam outlet connections with hose

INSTALLATION

WARNING

Preventing back pressure/abnormal operation in dual cylinder humidifi ers and installations where two individual units are

connected to a single dispersion panel.

Read and follow all steam hose installation instructions. Failure to follow these instructions could result in excessive back pressure or

abnormal operation of the unit. Severe personal injury or damage to the unit may result.

Notes:

• For horizontal runs longer than 5' (1.5 m) or vertical runs long than 10'

(3m), tubing is required. Do not use steam hose.

• See Table 61-1 for optional kits listed below.

* Provided in optional connector kit Part No. 191070-101

** Provided in optional connector kit Part No. 191070-002

*** Provided in optional connector kit Part No. 162825-202F

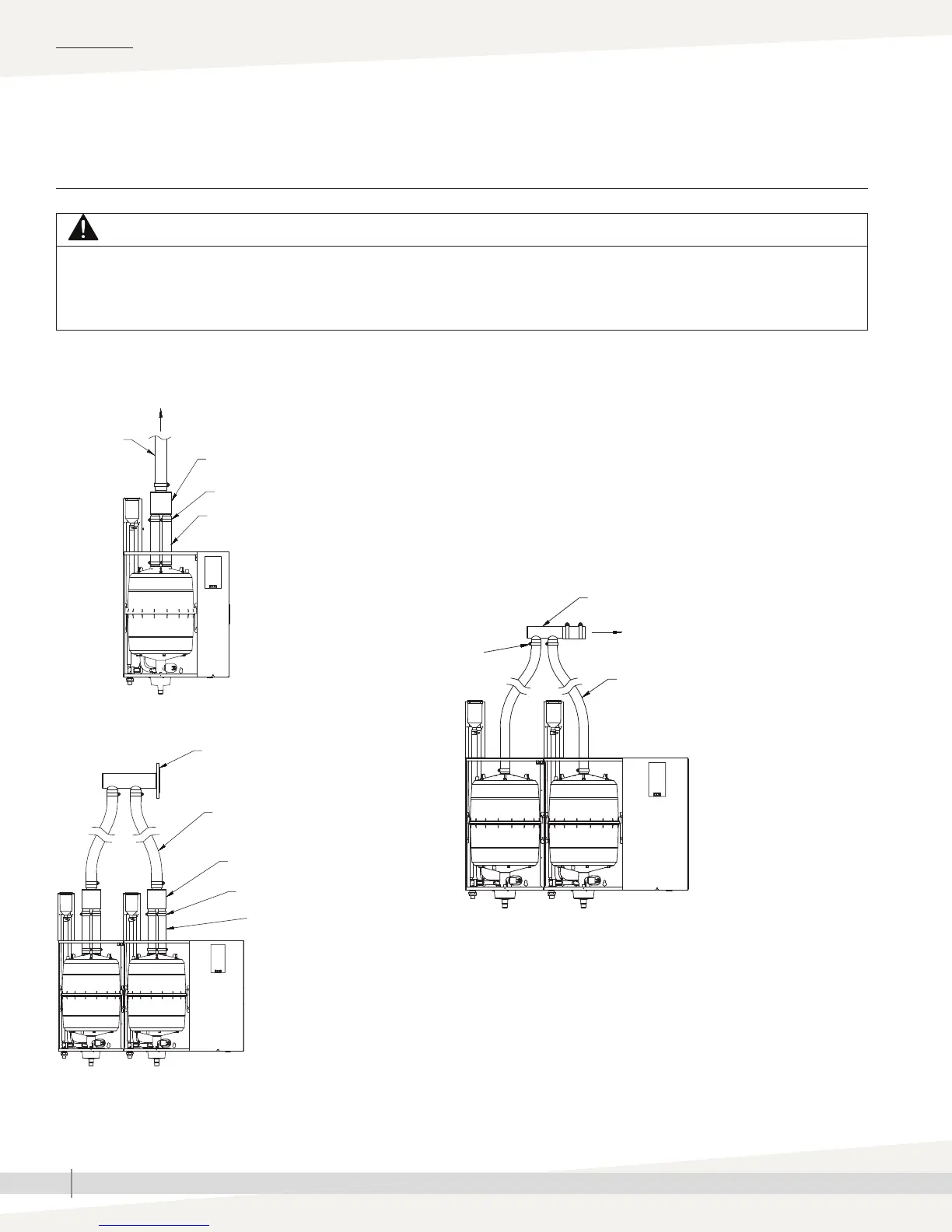

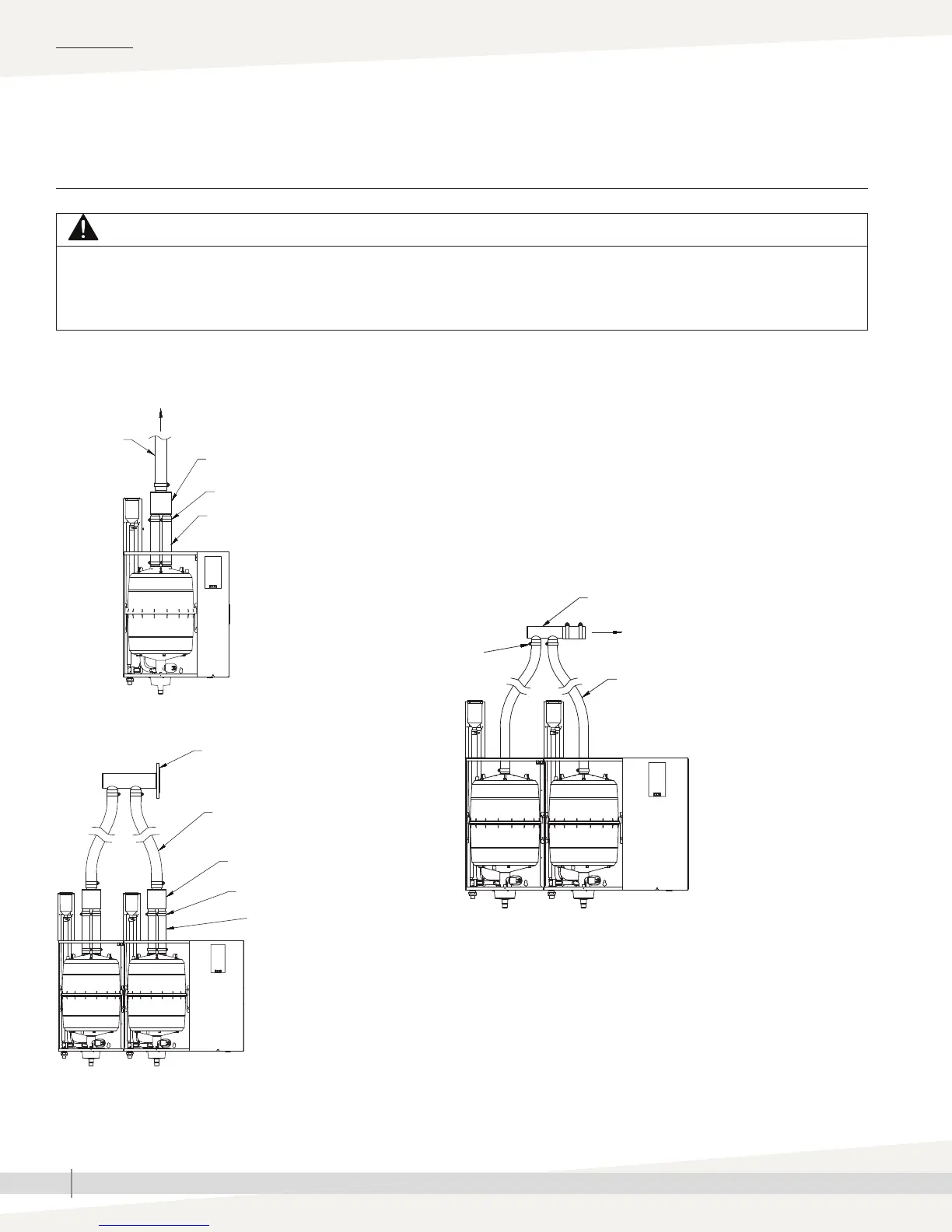

FIGURE 24-1: STEAM OUTLET CONNECTIONS WITH HOSE, MODELS XTP 033 THROUGH XTP096 WITHIN 10' (3 M) OF

DISPERSION ASSEMBLY

Dispersion:

2" (DN50)

steam hose,

10' (3 m)

maximum

Stainless steel Y connector*

Hose clamp*

OM-7981

OM-7979

Models XTP 033, 042, and 048

1½" (DN40) steam hose*,

12" (305 mm) long

Model XTP 050

OM-7980-XT

Stainless steel Y connector*

Hose clamp*

1½" (DN40) steam hose*,

12" (305 mm) long

2" (DN50) steam hose. Each cylinder

to connect to dispersion separately. For

distance greater than 10', use hard pipe.

3" (DN80) fl ange connection***

attaches directly to dispersion

Models XTP 067 through 096

To dispersion assembly

Hose clamp**

1½" (DN40) steam hose. Each cylinder

to connect to dispersion separately. For

distance greater than 10', use hard pipe.

Steam hose** attaches directly to

dispersion, 2" (DN50) on Ultra-sorb and

Rapid-sorb

Stainless steel tube connector**

Loading...

Loading...