8. CYCLE MONITORING

1) TIMER – TIME ONLY

The Lubrication cycle is simply operated

according to a preset Timer value.

Therefore, no input is monitored to confirm

the correct completion of the lubrication

cycle.

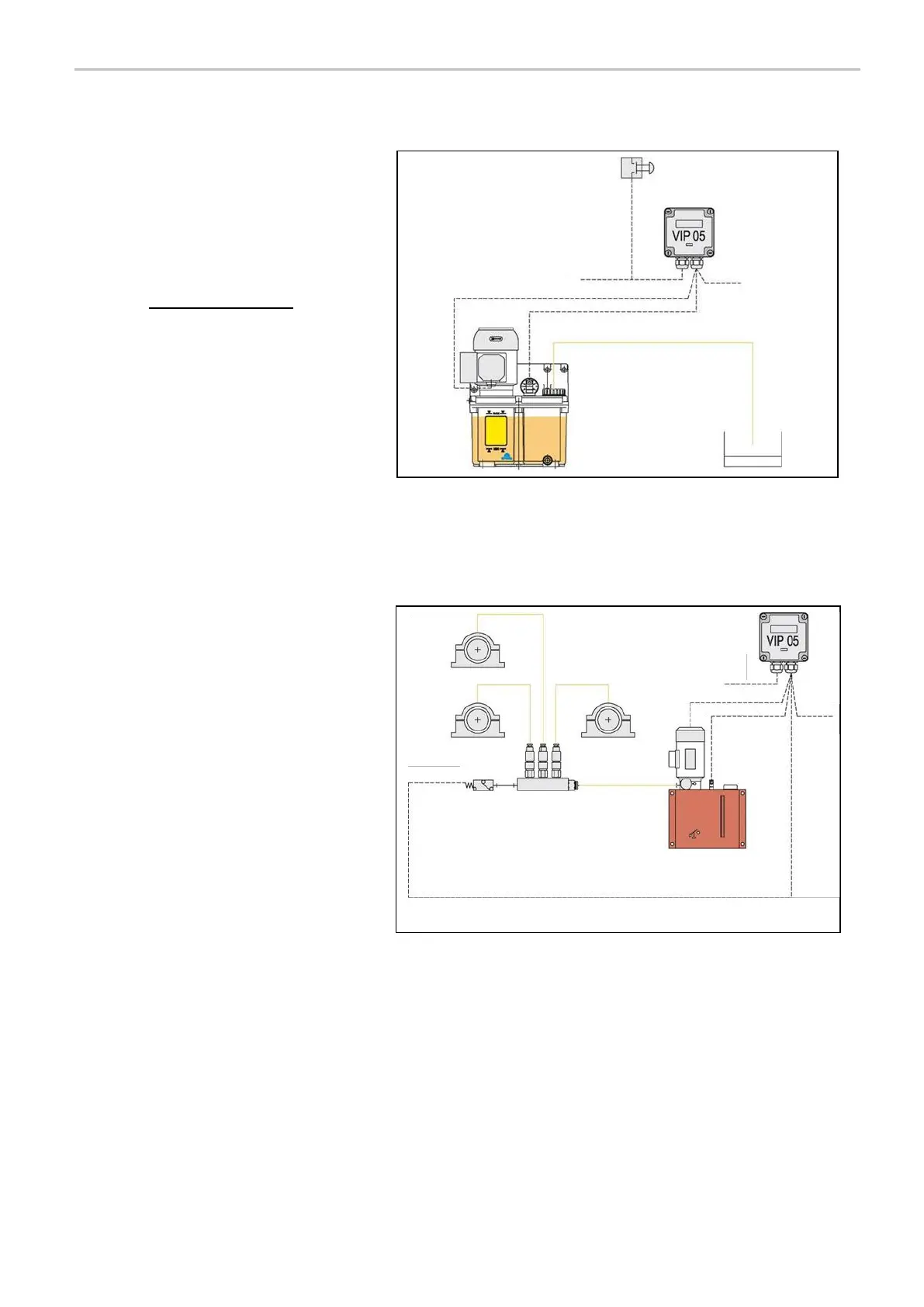

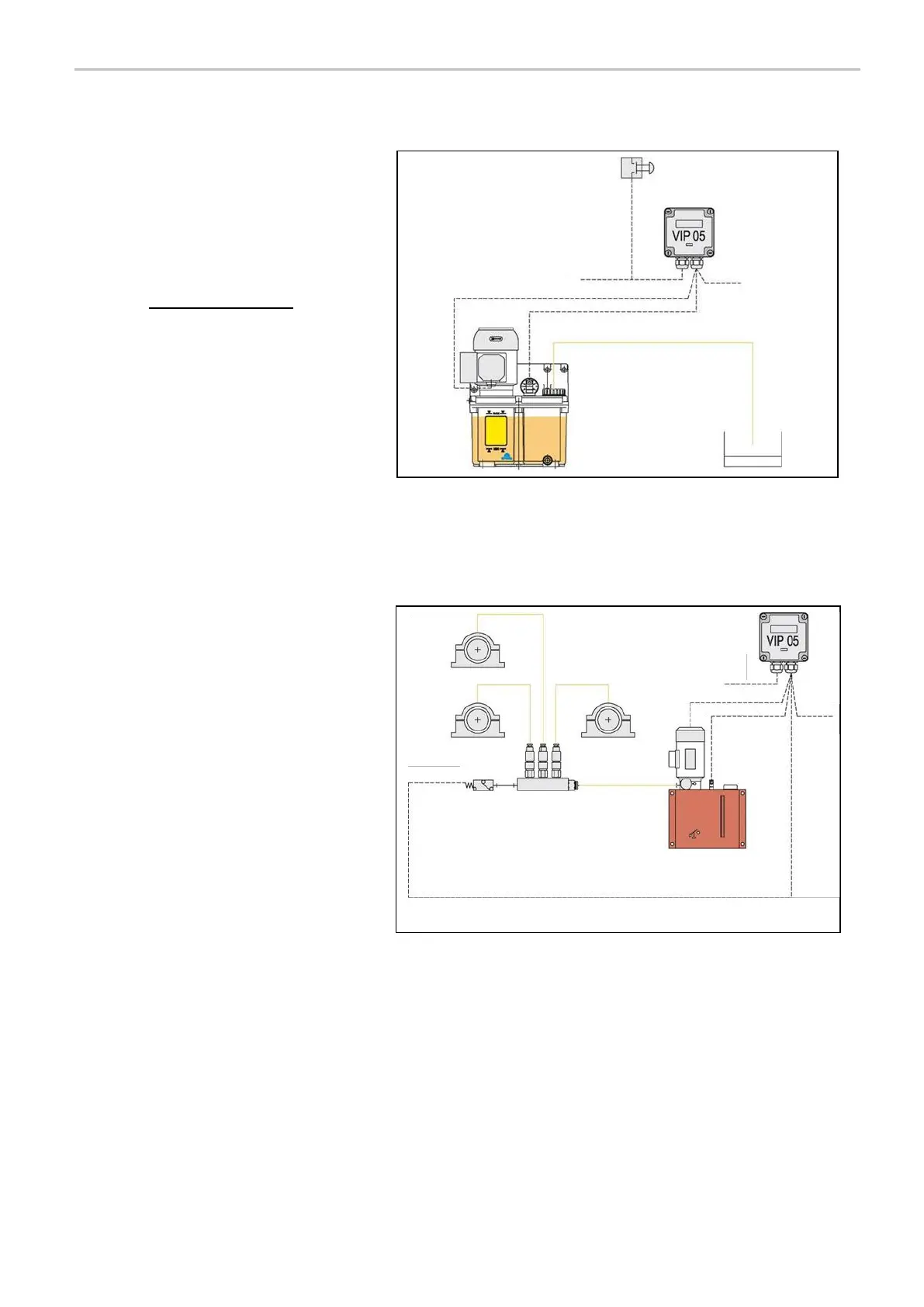

2) PS – PRESSURE SWITCH

Pressure switch monitoring is typically used

in injector system.

The VIP5 will monitor input P1 to verify that

it is an OPEN contact at the start of the

cycle.

The pump is activated and the pressure

switch must CLOSE within a timeout period

otherwise a cycle alarm is generated.

Once the P1 contact is closed, a DELAY

timer checks that the switch is not broken

for a set time before switching off the

pump. This ensures that pressure spikes at

the start of a lubrication cycles on long lines

are filtered out.

A WAIT timer can be set to allow the

injectors to reset when using multi cycle

configuration.

Loading...

Loading...