30

6 - HYDRONIC PIPING

6.1 General

• Primary/Secondary piping required.

• Install piping in accordance with authority having

jurisdiction.

• Support system piping and safety relief valve discharge

piping. Boiler's internal piping and wall mount bracket can

be damaged if subjected to excessive weight.

NOTICE

The intended use of the internal heat exchanger pump

is a boiler loop. Do not use as a primary system pump.

• Size central heating pump (and domestic hot water pump,

if used) for system requirements only. Internal heat

exchanger pump compensates for pressure drop through

boiler internal piping and heat exchanger.

•

boiler.

• If oil is present in system water, use approved detergent

to wash system.

• It is necessary to semi-annually check the water quality of

central heating systems.

• Manufacturer recommends installation of magnetic dirt

separator in the hydronic system where there are cast

iron or steel components, or where the previous boiler

was a cast iron heat exchanger. The abrasive, extremely

heat exchange surfaces and accumulate in pump cavities

• Flush system to remove any solid objects such as metal

• Flush system until water runs clean and piping is free of

sediment.

•

separately. If purge valves and isolation valves are not

installed, install them to properly clean the system.

• When purging installations that include standing iron

radiators and systems with manual vents at high points,

start with nearest manual air vent. Open the vent until

working toward furthest air vent.

• Install a basket strainer if large amounts of sediment is

present. Keep basket clear of sediment build up.

• Manufacturer recommends a water treatment product be

used for sediment removal.

• Ensure piping in the heating system has an oxygen

barrier.

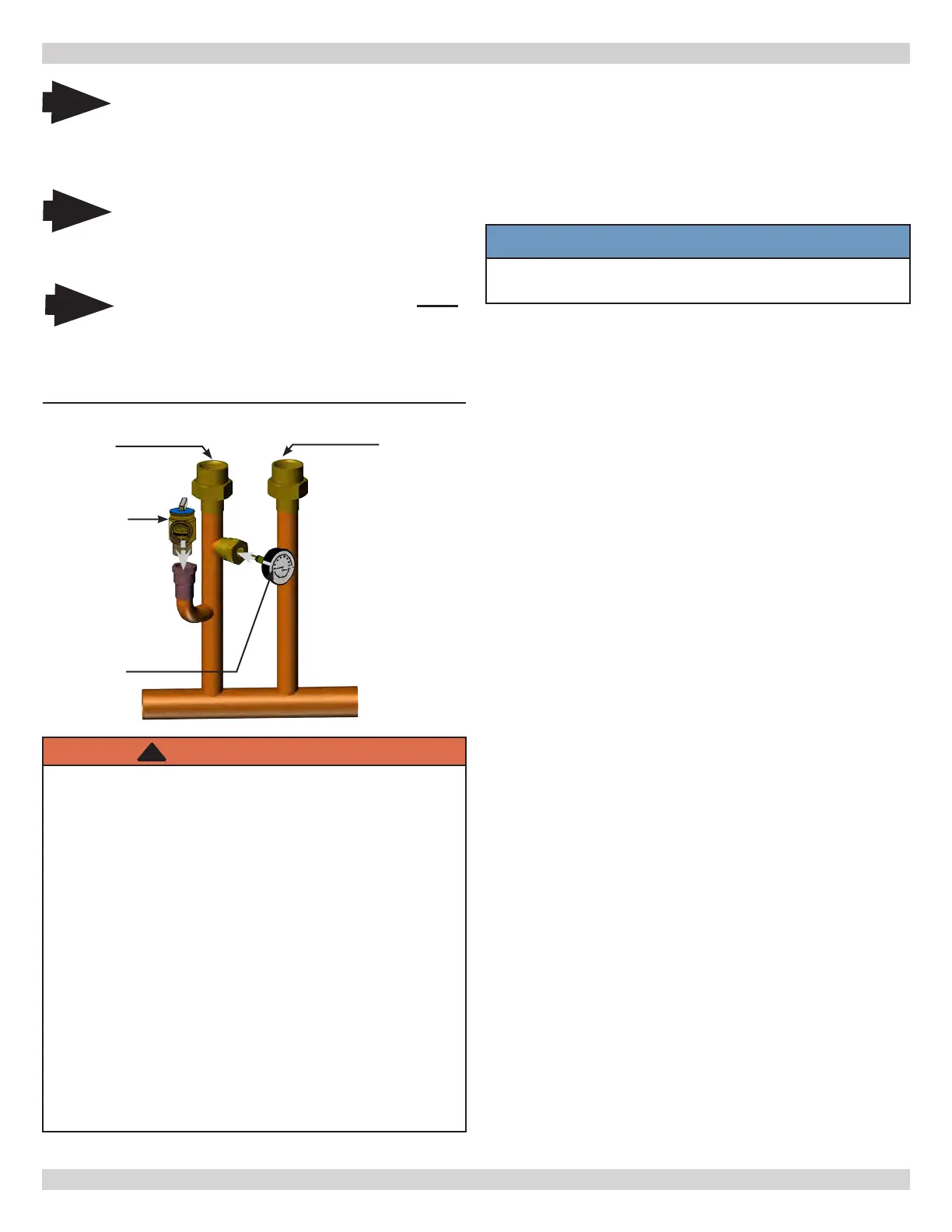

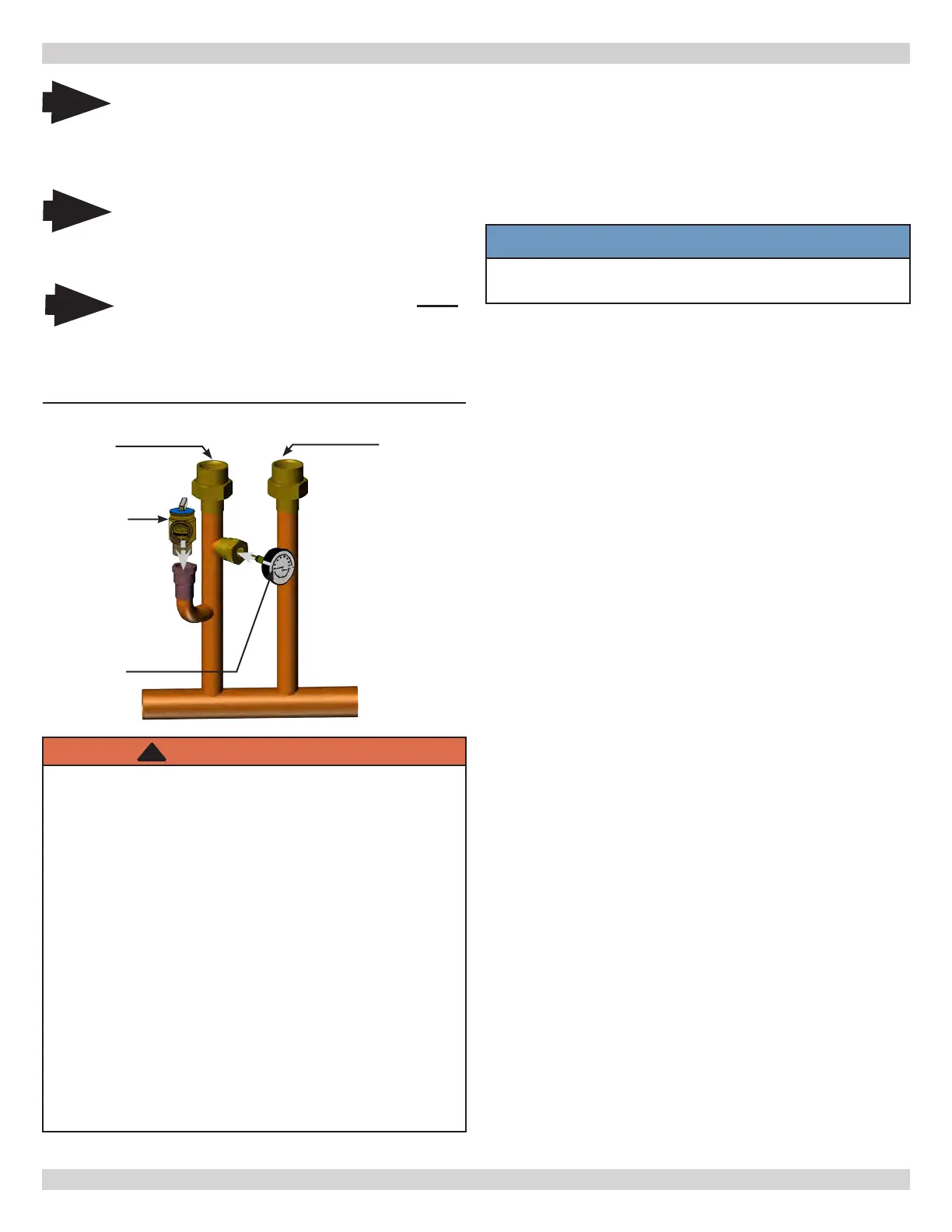

FIGURE 6-1 Safety Relief Valve

Note

Boiler rated at 50 psig (345 kPa) maximum

allowable working pressure. Boiler provided with

30 psig (206 kPa) safety relief valve.

WARNING

• Poison hazard. Ethylene glycol is toxic. Do not use

ethylene glycol.

• Never use automotive or standard glycol antifreeze,

even ethylene glycol made for hydronic systems.

• Ethylene glycol can attack gaskets and seals used in

hydronic systems.

• Do not use petroleum based cleaning or sealing

compounds boiler system.

•

water.

• Use only inhibited propylene glycol solutions

with closed water heating system.

•

glycol before installing new Boiler.

• Provide user with Material Safety Data Sheet

!

Safety Relief Safety Relief

ValveValve

Note

When installing safety relief valve it must be

installed in a vertical position with spindle at

top.

TP GaugeTP Gauge

System SupplySystem Supply

System ReturnSystem Return

Note

System pressure above 43 psi [2.96 bar] WILL

result in boiler shutting down.

240013360

REV A [07/01/2021]

Loading...

Loading...