52

NOTICE

During initial ignition, burner may not ignite. This may

cause boiler to shut down until any air in gas pipes is

vented. Repeat ignition procedure until gas reaches the

burner. To reset boiler operation, press

for at least

2 seconds.

9.10 De-Aeration Function

Used to eliminate air inside the heating circuit when boiler

is installed or after maintenance when water is drained from

primary circuit.

1.

Press buttons together and hold for 6 seconds.

On appears on display for a few seconds, followed by

program row 312.

2.

10 minutes. Function will automatically stop at end of the

cycle.

3.

To manually exit this function, press buttons

together and hold for 6 seconds.

9.11 Commission Set Up (Gas) - Changing The Type

Of Gas

During the rst installation boiler carries out an automatic

commissioning function.

The system is able to detect the gas type present in the

network.

Correct gas type setting, is made by pressing two buttons at

the same time, see section 9.6 Commissioning.

Change of gas type is made after

• Change parameter P02. See section 9.6

Commissioning and section 9.15 Parameter Settings.

• Check minimum gas pressure is suitable for selected gas:

minimum gas pressure is determined with boiler operating

source operational as well (whole house load)

Gas A (NG) = 3.5" (8.7 mbar)

Gas E (LPG) = 8.0" (19.9 mbar)

• Place supplied label with indication of gas type close to

the data plate of boiler replacing the original.

• Perform Automatic Calibration Function - Section 9.8.

• Manufacturer recommends

verication of CO2 concentration

on the ue.

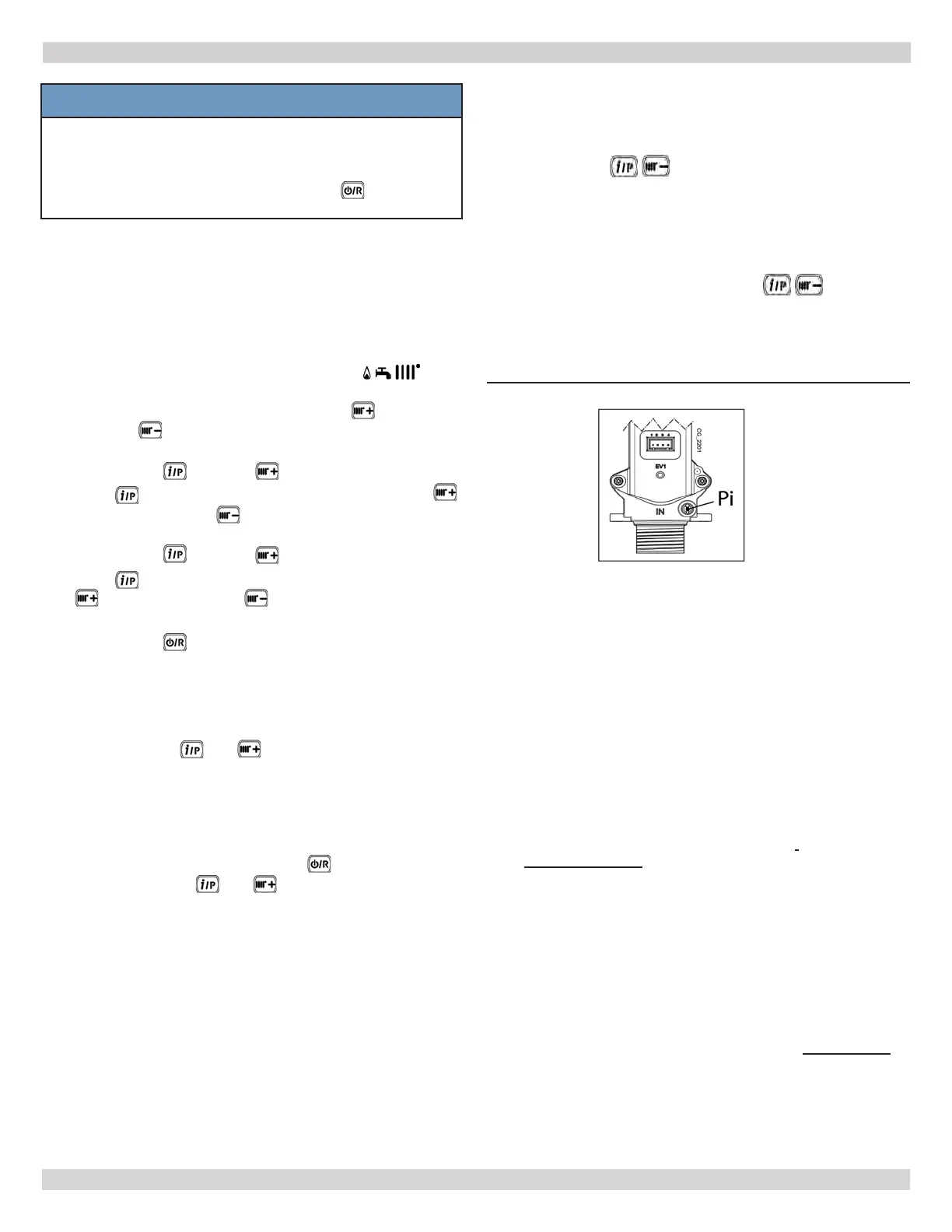

FIGURE 9-3 - Gas Inlet Tap - Pi

9 - START UP PROCEDURE

PI = Gas Supply Inlet Pressure Tap

IMPORTANT INFORMATION

A. If venting or gas recognition function is interrupted

by power blackout, start function again when power is

restored. Press

and together and hold at same

time for at least 6 seconds.

B. If display shows fault E118 (low pressure in hydraulic

pressure.

C. If gas recognition function is interrupted due

to fault (e.g.: E133 no gas) press

to

reset. Then press and (for at least

6 seconds) to restart the function again.

If gas recognition function is interrupted due to

overheating, restart function by pressing and holding

down together for at least 6 seconds.

D. Combustion of this appliance has been factory controlled,

calibrated and set for operation with Gas A (Natural

Gas).

E. During Gas Type Control Function, combustion ratio will

increase for a short period of time while gas type is being

established.

9.9 Manual Calibration Function:

Manual Calibration phase starts at the end of the Automatic

Calibration.

The Display shows the boiler power and adjustment of the

CO2 value (parameter setting) during Manual Calibration

sequence.

The process begins at minimum power.

A. After Automatic Calibration sequence with

minimum power combustion by pressing

to lower %

CO

2

, and to raise % CO

2

.

B.

range, press

and then to reach ignition power.

C. Press to adjust ignition power combustion. Press

to lower % CO

2

, and to raise % CO

2

.

D.

range, press

and then to reach maximum power.

E. Press to adjust maximum power combustion. Press

to lower % CO

2

, and to raise % CO

2

.

F.

range, press

to exit Manual Calibration Function ESC

is displayed on the sceen..

240013360

REV A [07/01/2021]

Loading...

Loading...