For safe, efficient operation, the vent damper and all flue

product carrying areas of the appliance must be checked

annually byyou, with particular attention given to deterioration

from corrosion or other sources. If you see corrosion or other

deterioration,contactyour heatingcontractorfor repairs. Check

vent damper operation as follows:

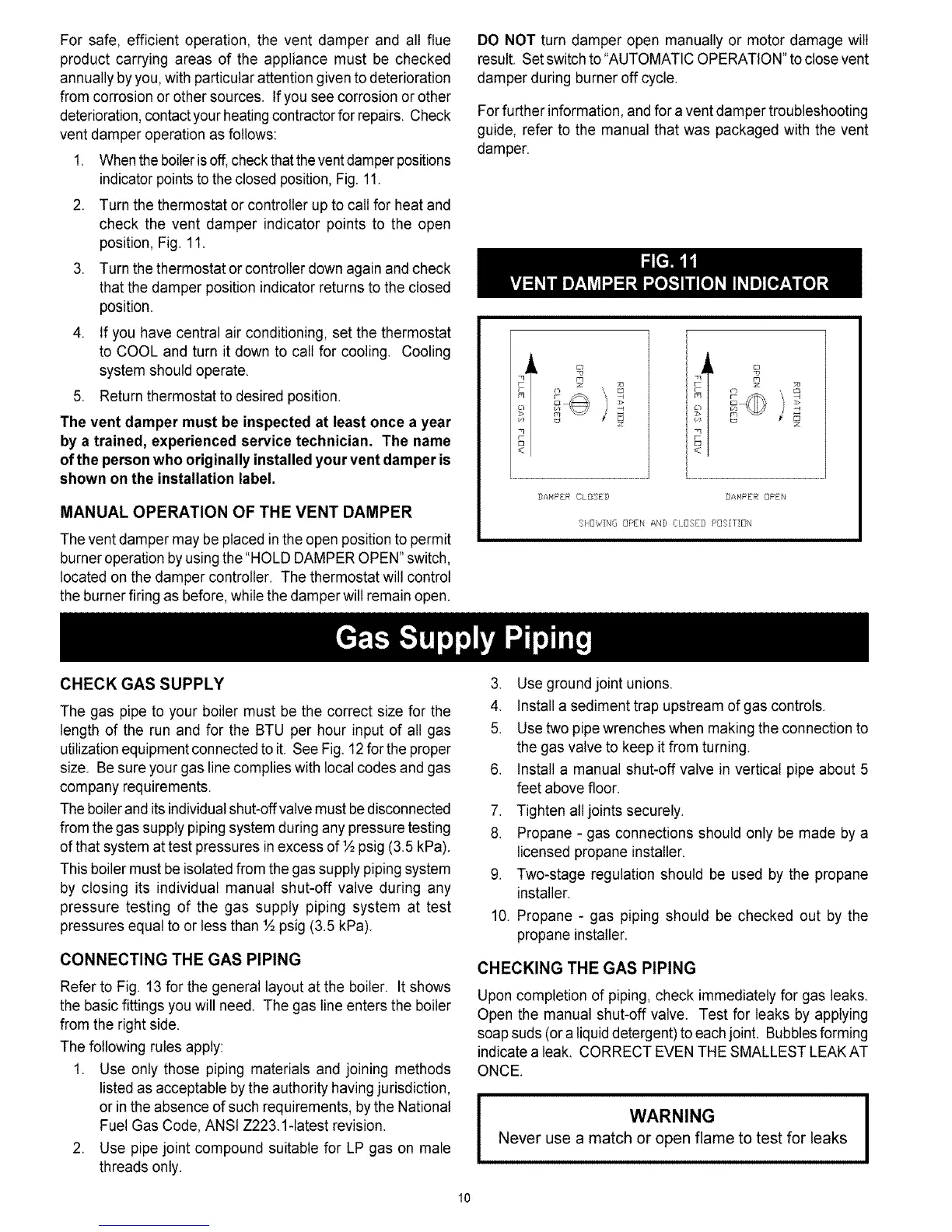

1. When the boilerisoff, checkthatthe ventdamper positions

indicator points to the closed position, Fig. 11.

2. Turn the thermostat or controller up to call for heat and

check the vent damper indicator points to the open

position, Fig. 11.

3. Turn the thermostat or controller down again and check

that the damper position indicator returns to the closed

position.

4. If you have central air conditioning, set the thermostat

to COOL and turn it down to call for cooling. Cooling

system should operate.

5. Return thermostat to desired position.

The vent damper must be inspected at least once a year

by a trained, experienced service technician. The name

ofthe person who originally installed your vent damper is

shown on the installation label.

MANUAL OPERATION OF THE VENT DAMPER

The vent damper may be placed in the open position to permit

burner operation by using the "HOLD DAMPER OPEN" switch,

located on the damper controller. The thermostat will control

the burner firing as before, while the damper will remain open.

DO NOT turn damper open manually or motor damage will

result. Set switchto "AUTOMATIC OPERATION" to close vent

damper during burner off cycle.

Forfurther information, and for a vent damper troubleshooting

guide, refer to the manual that was packaged with the vent

damper.

z

DAMPER CLOSED DAMPER DPEN

SHOWING OPEN AND CLOSED POSITION

CHECK GAS SUPPLY

The gas pipe to your boiler must be the correct size for the

length of the run and for the BTU per hour input of all gas

utilizationequipment connected to it. See Fig. 12for the proper

size. Be sure your gas line complies with local codes and gas

company requirements.

The boilerand its individualshut-off valve must bedisconnected

from the gas supply piping system during any pressure testing

of that system attest pressures inexcess of ½ psig (3.5 kPa).

This boiler must be isolated from the gas supply piping system

by closing its individual manual shut-off valve during any

pressure testing of the gas supply piping system at test

pressures equal to or tessthan ½ psig (3.5 kPa).

CONNECTING THE GAS PIPING

Refer to Fig. 13 for the general layout at the boiler. It shows

the basic fittings you will need. The gas line enters the boiler

from the right side.

The following rules apply:

1. Use only those piping materials and joining methods

listed as acceptable by the authority having jurisdiction,

or in the absence of such requirements, by the National

Fuel Gas Code, ANSI Z223.1-1atestrevision.

2. Use pipe joint compound suitable for LP gas on male

threads only.

3. Use ground joint unions.

4. Install a sediment trap upstream of gas controls.

5. Use two pipe wrenches when making the connection to

the gas valve to keep it from turning.

6. Install a manual shut-off valve in vertical pipe about 5

feet above floor.

7. Tighten all joints securely.

8. Propane - gas connections should only be made by a

licensed propane installer.

9. Two-stage regulation should be used by the propane

installer.

10. Propane - gas piping should be checked out by the

propane installer.

CHECKING THE GAS PIPING

Upon completion of piping, check immediately for gas leaks.

Open the manual shut-off valve. Test for leaks by applying

soap suds (ora liquiddetergent) to each joint. Bubblesforming

indicate a leak. CORRECT EVEN THE SMALLEST LEAKAT

ONCE.

I WARNING I

Never use a match or open flame to test for leaks

10

Loading...

Loading...