Checktobesureyouhavetherightsizeboilerbeforestartingtheinstallation.

_,eeratingandcapacitytableonpreviouspage.Alsobesurethenewboileris

_orthetypeofgasyouareusing.Checktheratingplateontherightsideofthe

boiler.

Youmustseethattheboilerissuppliedwiththecorrecttypeofgas,freshair

forcombustion,andasuitableelectricalsupply.Also,theboilermustbecon-

nededtoasuitableventingsystemandanadequatepipingsystem.Finally,a

thermostat,properlylocated,isneededforcontroloftheheatingsystem.Ifyou

haveanydoubtsastothevariousrequirements,checkwithlocalauthorities

andobtainprolessionathelpwhereneeded.Takethetimetocompleteall of

thestepsforSAFEandPROPERoperationoftheheatingsystem.

Ifthisboilerisinstalledinabuildingunderconstruction,specialcaremustbe

takentoinsureacleancombustionairsupplyduringtheconstructionprocess.

Airborneparticulatessuchasfromdrywalldustandfromfiberglassinsulation

canclogtheburnerportsandcauseincompletecombustionandsooting,

Theseboilersaredesignedforuseinclosedheatingsystemswhereallofthe

steamisreturnedtotheboilerascondensateandtheamountofmake-upwater

requiredisminimal.Theseboilersarenotdesignedfororintendedforusein

opensystemsofprocessapplicationsusing100%make-upwater.Damageto

theboilerresultingfromsuchuseshallnotbecoveredunderthewarranty.

Whererequiredbytheauthorityhavingjurisdiction,theinstallationmustcon-

formtoAmericanSocietyofMechanicalEngineersSafetyCodeforControls

andSafetyDevicesforAulomaticallyFiredBoilers,No.CSD-1.

Theinstallationmustconformto therequirementsof theauthorityhaving

jurisdictionor,intheabsenceofsuchrequirements,totheNationalFuelGas

Code,ANSIZ223.1-1atestrevision.

Thefollowingstepsareallnecessaryforproperinstallationandsafeoperation

ofyourboiler.

1. LOCATINGTHEBOILER 5. GASSUPPLYPIPING

2. FRESHAIRFORCOMBUSTION 6. ELECTRICALWIRING

3, INSTALLATION- SYSTEMPIPING 7. CHECKING&ADJUSTING

4. CHIMNEY& VENTPIPECONNECTION

KEEP BOILER AREA CLEAN AND FREE FROM COMBUSTIBLE MATERIALS,

GASOLINE AND OTHER FLAMMABLE VAPORS AND LIQUIDS

1.Selectlevellocationascentralizedwithpipingsystem,andasnearchim-

neyaspossible.

2.Placecratedboilerat selectedlocation,removecratebypullingcrate

sidesfromtopandbottomboards.Combustiblefloors:Whenboileristo

beinstalledonacombustiblefloor,aSpecialBasePlatemustbeused-

1.46-14-031(2-6Section)or146-14-032(7-9Section).Thisboilermust

notbeinstalledoncarpeting.

3.I1thisboilerisequippedwithcastironburners,it isalsoequippedwith

stainlesssteelwiretiesto holdlhebackendolthecastironburnersin

placeduringshipping.In orderto removetheburnersforcleaningor

inspection,thewiretiesmustbecutandremoved.Thewiretiesare

accessedthroughthecombustionair openingonthebacksideofthe

boileratthebottomoftherearjacketpanel,andmaybecutwithanywire

cuttingpliers.Iftheboileris installedatitsminimumclearancesit may

bedifficulttoreachthewiretiesaftertheboileris installed,andthewire

tiesshouldbeculnow.Thewireliesareonlyneededduringshipping,

anddo notneedtobereplaced.Boilersequippedwilh stainless

steelburnersdonothavewireties andthisinformationdoes

notapply.

4.Boileristobelevel.Metalshimsmaybeusedunderbaselegsforfinal

leveling.

5.Equipmentshallbeinstalledina Iocalioninwhichthefacilitiesforven-

tilationpermitsatisfactorycombustionof gas,properventing,andmain-

tenanceofambienttemperatureatsalelimitsundernormalconditionsof

use,Equipmentshallbelocatedsoasnotto interferewithpropercircu-

lationofair.Whennormalinfiltrationdoesnotprovidethenecessaryair,

outsideair shall be introduced(See Page4 - "FreshAir for

Combustion").

6.Adviseownerto keepairpassagesfreeofobstructions.Ventilatingand

combustionairmustenterboilerroomwithoutrestrictions.

7. Theboilershallbeinstalledsuchthattheautomaticgasignitionsystem

componentsareprotectedfromwater(dripping,spraying,rain,etc.)dur-

ingapplianceoperationandservice(condensatetrap,controlreplace-

ment,etc.).

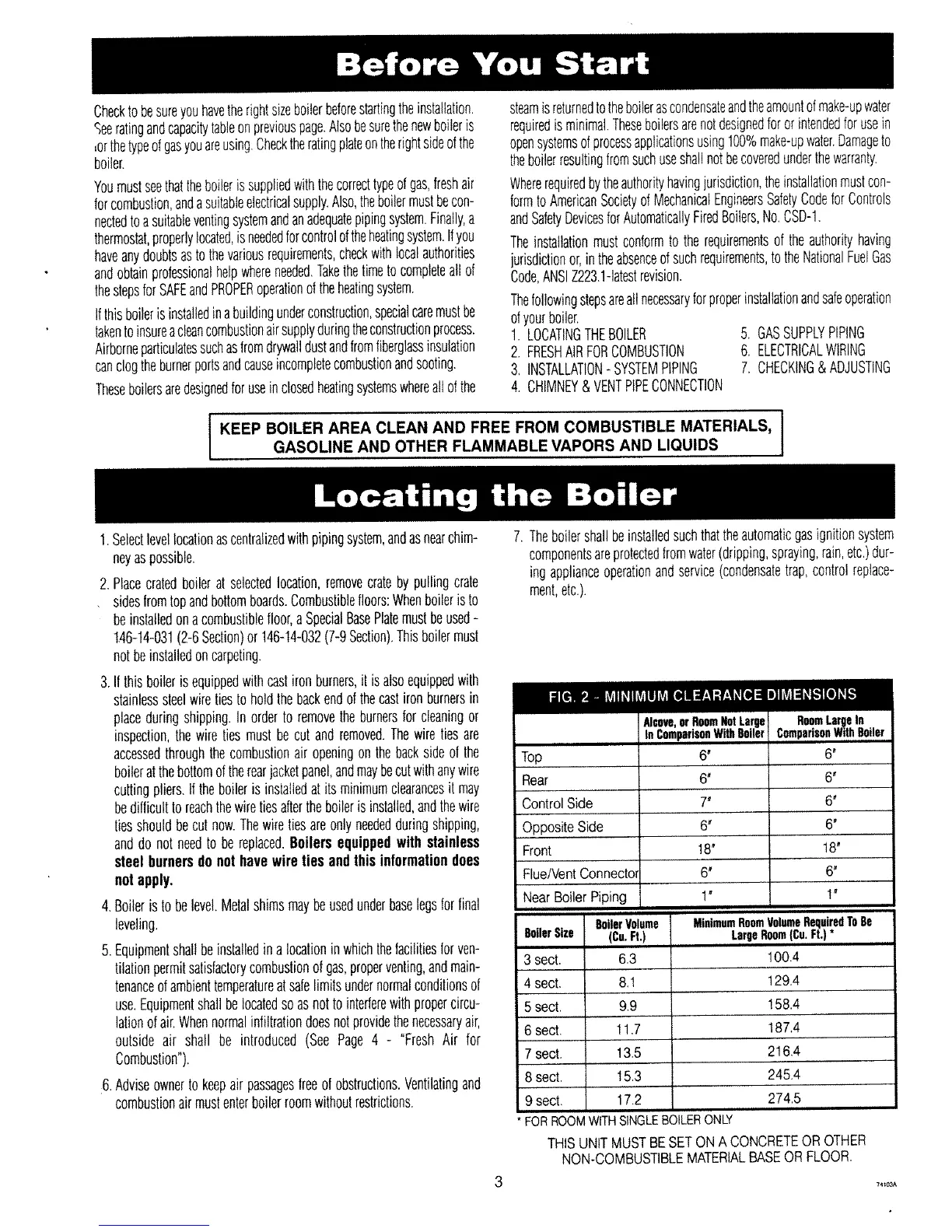

Top

Rear

Control Side

Opposite Side

Front

Flue/Vent Connectol

Near Boiler Piping

BoilerVolume

BoilerSize (Cu.Ft.)

3 sect. 6.3

4 sect. 8,1

5 sect, 9.9

6 sect. 11,7

7 sect. 13.5

8 sect. 15.3

9 sect. 17.2

* FOBROOMWITHSINGLEBOILERONLY

Alcove,orRoomNotLarge

InComparisonWith6oiler

6" 6"

6" 6'

7" 6"

6" 6'

18" 18'

6" 6'

1' 1"

MinimumRoomVolumeRequiredToBe

LargeRoom(Cu.Ft.)*

100.4

129.4

!58.4

187,4

216,4

245,4

274,5

RoomLargeIn

ComparisonWithBoiler

THIS UNIT MUST BE SET ON A CONCRETEOR OTHER

NON-COMBUSTIBLEMATERIALBASEOR FLOOR.

?4_oaA

Loading...

Loading...