The near boiler piping, that is the piping around the boiler,

must be considered as part of the boiler for proper water

level control, and to produce dry steam. Correct near boiler

piping is crucial to the proper operation of the boiler and

the heating system. Followthese recommendations carefully.

1. Place boiler in selected location, as near chimney as

possible.

2. Install the pop safety valve, using the furnished 3/4"

coupling, intothe 3/4" pipe nipple on the top ofthe boiler.

Make a discharge pipe, using 3/4' pipe (not furnished}

to carry the water or steam to a nearby drain. Do not

connect the discharge pipe directly to a drain but leave

an air gap. The downstream end of the discharge pipe

must be unthreaded. No shutoff of any description shall

be placed between the pop safety valve and the boiler,

,

,

or on discharge pipes between such safety valves and

the atmosphere. Installation of the pop safety valve shall

conform to the requirements ofthe ANSltASME Boiler and

Pressure Vessel Code, Section IVThe manufacturer is not

responsible for any water damage.

This boiler is equipped with two 21/2"supply connections

and two 21/2"return connections, one each on both the

left and right sides of the boiler. Unused connections must

be plugged with the 21/2_ plugs (furnished}.

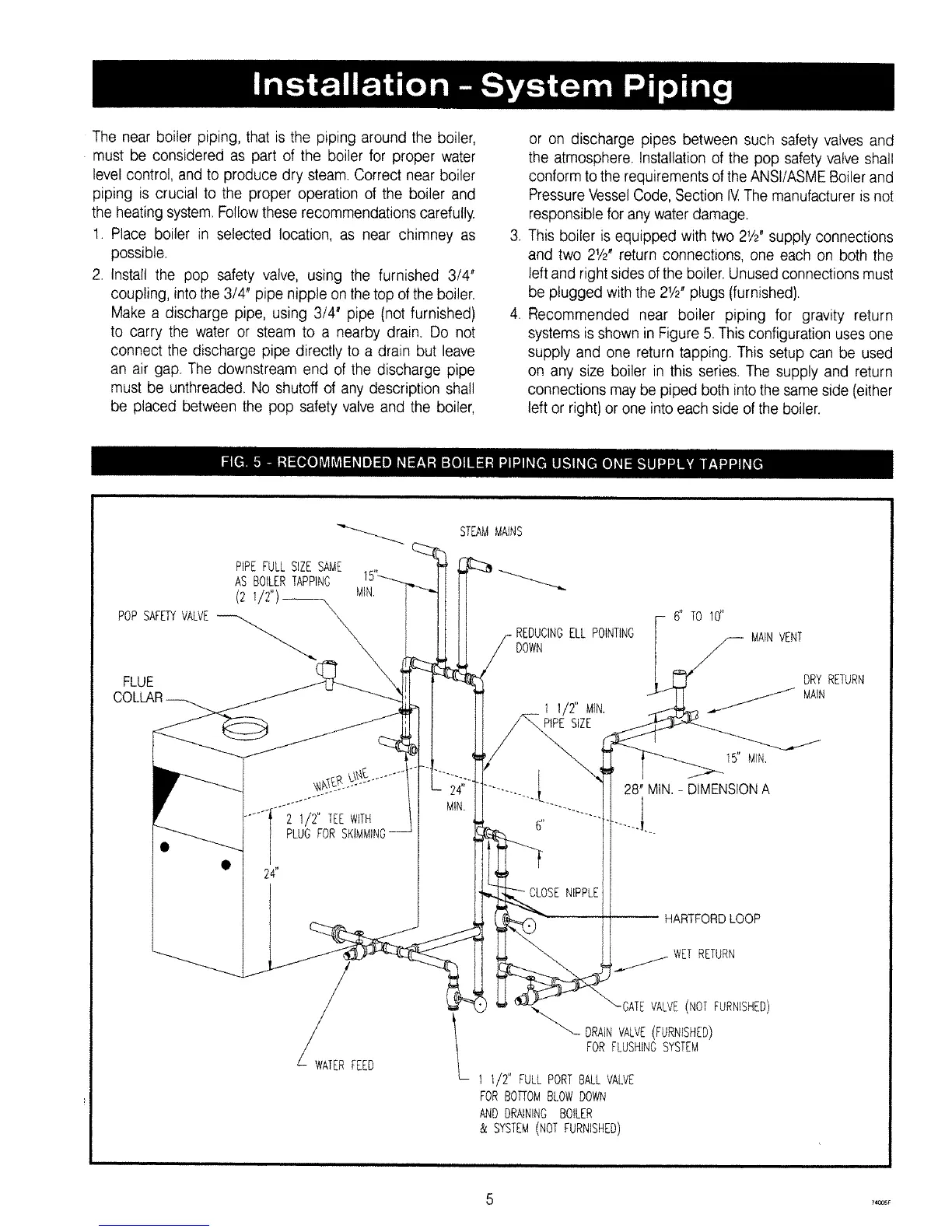

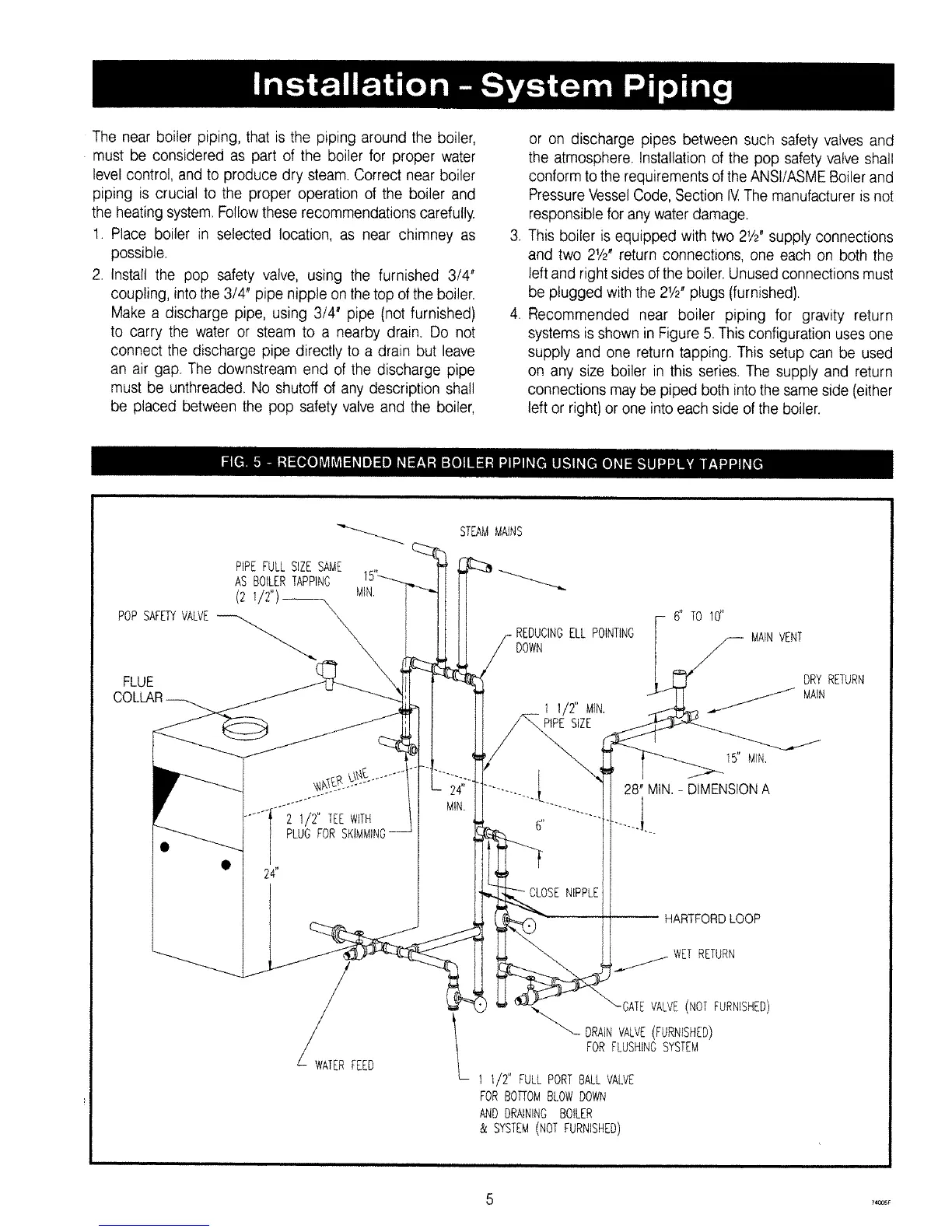

Recommended near boiler piping for gravity return

systems is shown in Figure 5. This configuration uses one

supply and one return tapping. This setup can be used

on any size boiler in this series. The supply and return

connections may be piped both into the same side (either

left or right} or one into each side of the boiler.

POP SAFETYVALVE

FLUE

PIPEFULLSIZESAME

AS BOILERTAPPING

(2 ii2")_ MIN'

2 1/2" TEE WiTH

PLUGFOR

• 24"

FEED

STEAMMAINS

REDUCINGELL POINTING

DOWN

6" TO 10"

MAINVENT

1 1/2" MtN.

PIPESiZE

NIPPLE

15' MIN,

28' MIN.- DIMENSIONA

I

-- HARTFORD LOOP

WET RETURN

GATEVALVE(NOTFURNISHED)

_"'--DRAiN VALVE(FURNISHED)

FOR FLUSHINGSYSTEM

I t/2" FULLPORTBALLVALVE

FOR BOTTOMSLOWDOWN

AND DRAININGBOILER

& SYSTEM(NOT FURNISHED}

DRY RETURN

MAIN

Z4OCBF

Loading...

Loading...