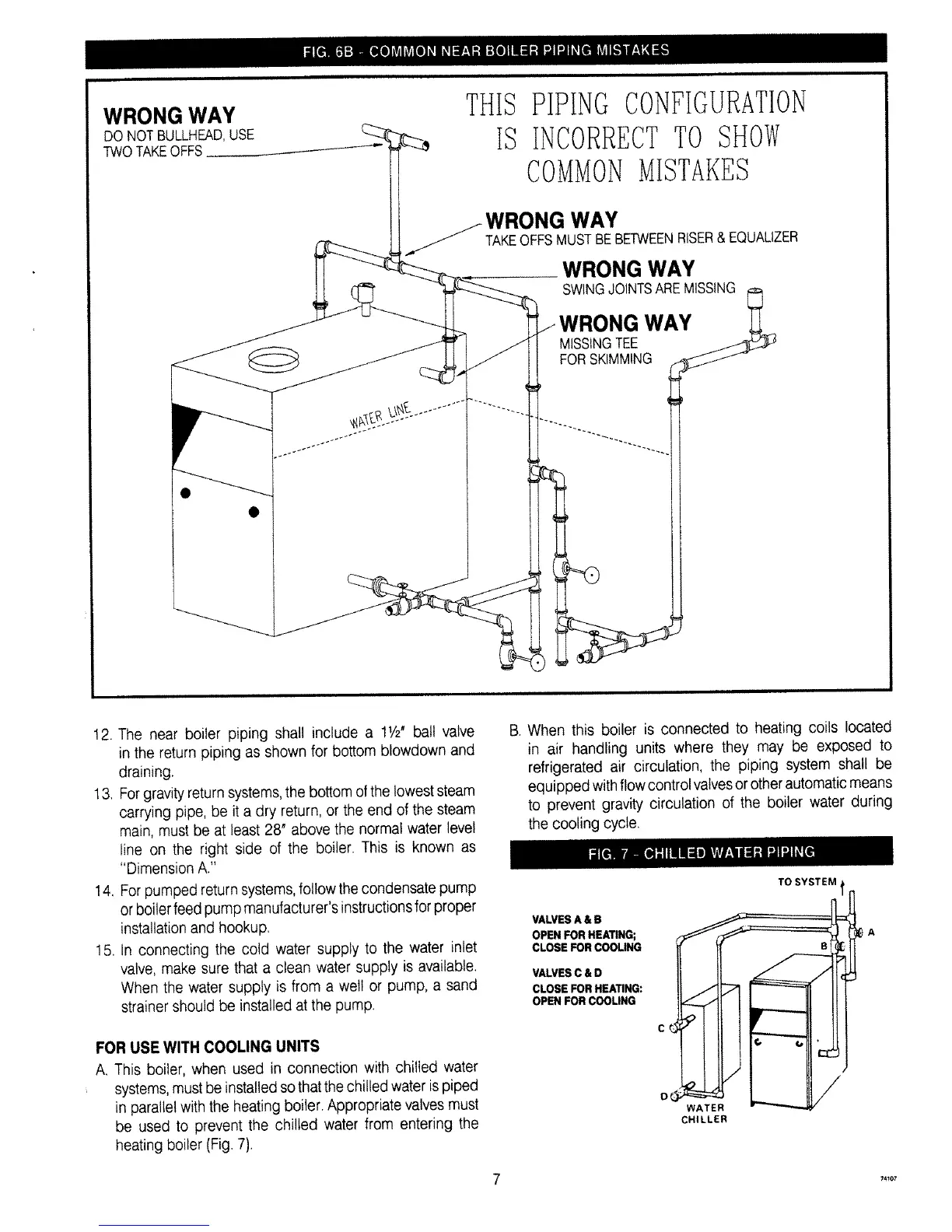

WRONG WAY

DONOTBULLHEAD,USE

TWOTAKEOFFS

THIS PIPING CONFIGURATION

tS INCORRECTTO SHOW

COMMONMISTAKES

WAY

TAKEOFFSMUSTBEBETWEENRISER&EQUALIZER

WRONG WAY

SWINGJOINTSAREMISSING

WRONG WAY

MiSSiNGTEE

FORSKIMMING

12. The near boiler piping shall include a 11h" ball valve

in the return piping as shown for bottom blowdown and

draining.

13. Forgravity return systems, the bottom of the lowest steam

carrying pipe, be it a dry return, or the end of the steam

main, must be at least 28" above the normal water level

line on the right side of the boiler. This is known as

"Dimension A."

14. For pumped returnsystems, follow the condensate pump

or boiler feed pump manufacturer's instructionsfor proper

installation and hookup.

15. In connecting the cold water supply to the water inlet

valve, make sure that a clean water supply is available.

When the water supply is from a welt or pump, a sand

strainer should be installed at the pump.

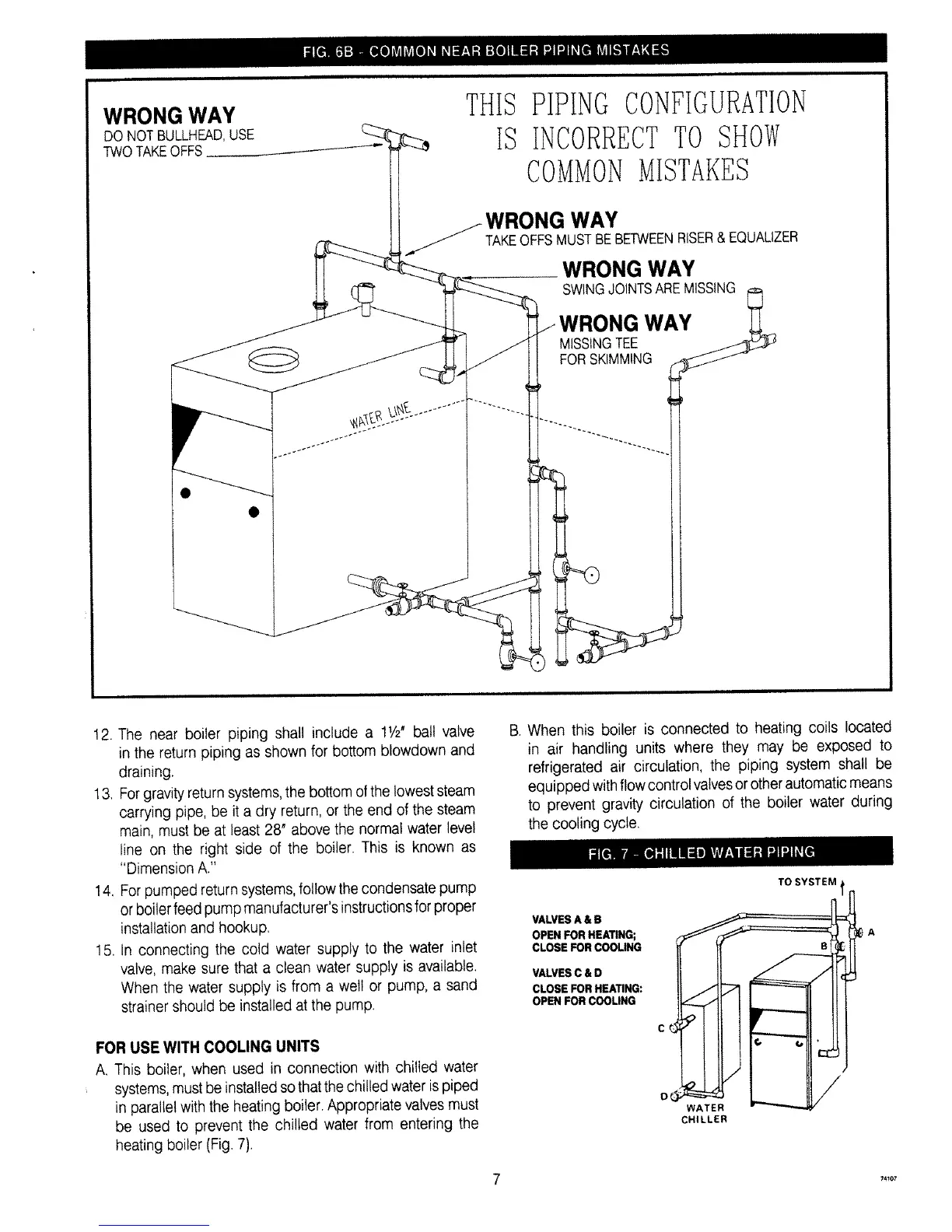

FOR USE WITH COOLING UNITS

A. This boiler, when used in connection with chilled water

, systems,mustbe installed so that the chilled water ispiped

in parallel with the heating boiler. Appropriate valves must

be used to prevent the chilled water from entering the

heating boiler (Fig.7).

B When this boiler is connected to heating coils located

in air handling units where they may be exposed to

refrigerated air circulation, the piping system shall be

equipped with flowcontrol valves or other automatic means

to prevent gravity circulation of the boiler water during

the cooling cycle.

VALVES A & B

OPEN FOR HEATING;

CLOSE FOR COOLING

VALVES C & O

CLOSE FOR HEATING:

OPEN FOR COOLING

WATER

CHILLER

TO SYSTEM t

74_o7

Loading...

Loading...