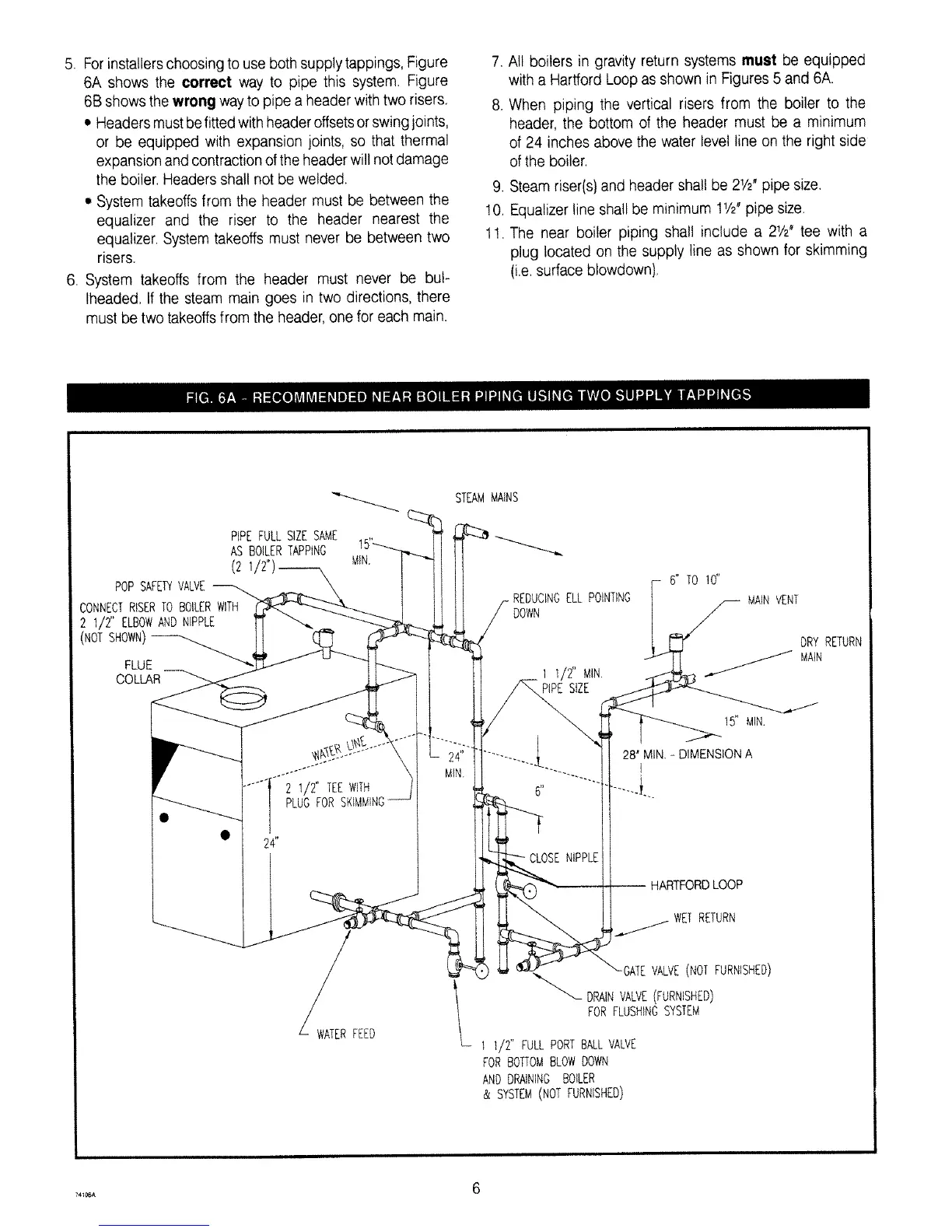

5. Forinstallers choosing to use both supply tappings, Figure

6A shows the correct way to pipe this system. Figure

6B showsthe wrong way to pipe a header with two risers.

• Headers must be fitted with header offsets orswing joints,

or be equipped with expansion joints, so that thermal

expansion and contraction of the header wilt not damage

the boiler. Headers shall not be welded.

• System takeoffs from the header must be between the

equalizer and the riser to the header nearest the

equalizer. System takeoffs must never be between two

risers.

6. System takeoffs from the header must never be bul-

lheaded. If the steam main goes in two directions, there

must be two takeoffs from the header, one for each main.

,

8.

All boilers in gravity return systems must be equipped

with a Hartford Loop as shown in Figures 5 and 6A.

When piping the vertical risers from the boiler to the

header, the bottom of the header must be a minimum

of 24 inches above the water level line on the right side

ofthe boiler.

9. Steam riser(s) and header shall be 21/2"pipe size.

!0. Equalizer line shall be minimum 11/2"pipe size.

11. The near boiler piping shall include a 21/2"tee with a

plug located on the supply line as shown for skimming

(i.e.surface blowdown).

PiPE FULLSIZE SAME

AS BOILERTAPPING

(2

POP SAFE_ VALVE

CONNECTRISERTO BOILERWITH

2 I/2" ELBOWANDNIPPLE

(NOTSHOWN)

FLUE

COLLAR

MIN,

....{"2112" W TN

PLUGFORS

24"

W_AT_RFEED

STEAMMAINS

REDUCINGELL POINTING

DOWN

6" TO t0"

I1/2" MIN.

PiPE StZE

15" MIN,

28" MIN - DIMENSION A

I

i

NIPPLE

HARTFORDLOOP

RETURN

-GATEVALVE(NOTFURNISHED)

_-- DRAINVALVE(FURNISHED)

FOR FLUSHINGSYSTEM

I ;/2" FULLPORTBALLVALVE

FORBOTTOMBLOWDOWN

ANDDRAINING BOILER

& SYSTEM(NOT FURNISHED)

MAINVENT

ORYRETURN

MAiN

_4106A 6

Loading...

Loading...