16 CA 251/301 M251EN2

Battery cell

Battery - Checking the

electrolyte level

EVERY 50 HOURS OF OPERATION (Weekly)

1

2

3

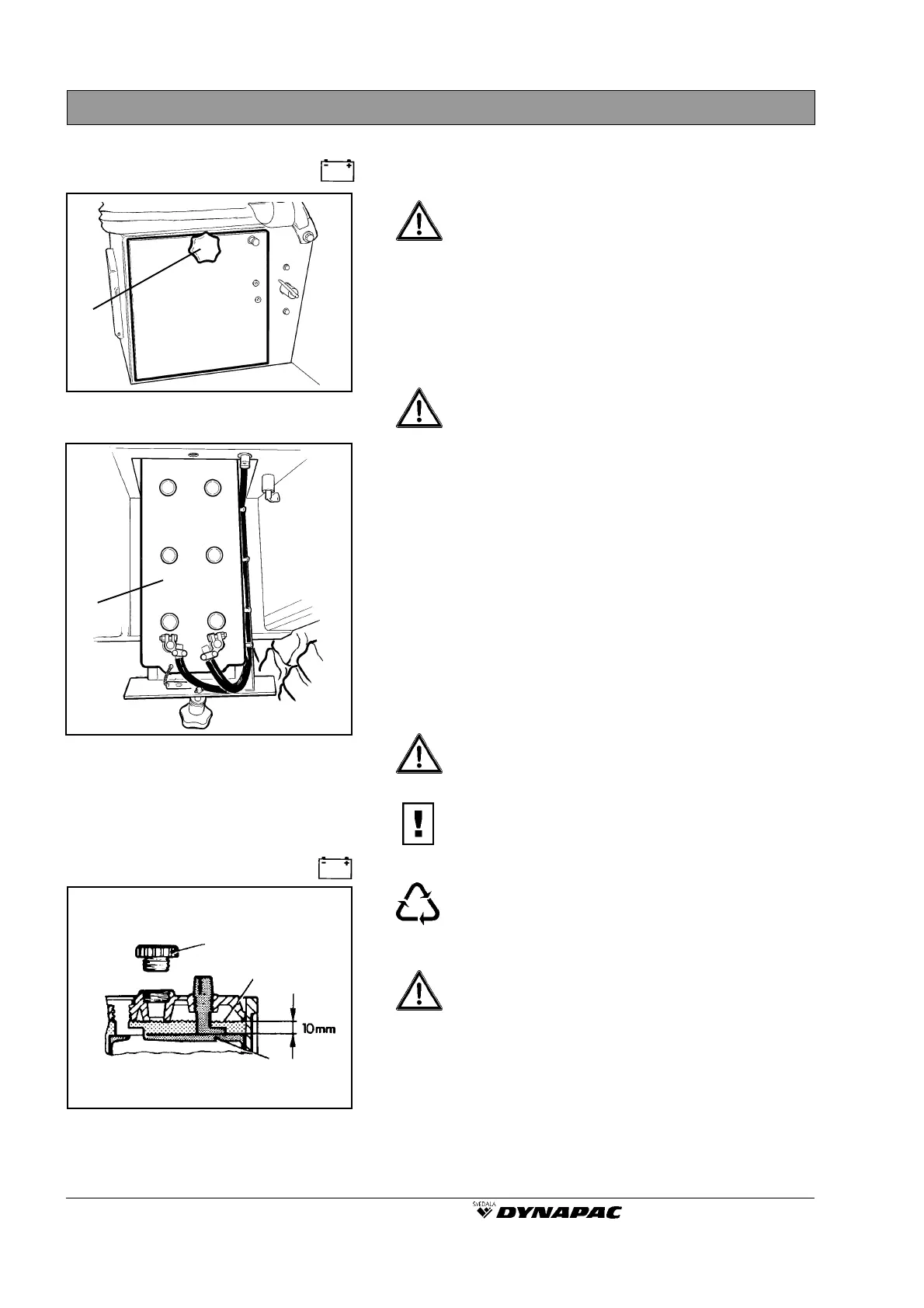

Fig. 22 Electrolyte level in battery

1. Cell cap

2. Electrolyte level

3. Plate

Never use a naked flame when checking

the battery. The electrolyte emits explosive

gas while the alternator is charging.

1. Turn the knob (1).

2. Pull out the battery shelf.

3. Wipe the top of the battery.

Wear protective goggles. The battery

contains corrosive acid. Flush with water

in the event of contact with the skin.

3. Take off the cell caps and check that electrolyte

level is about 10 mm (0.4") above the plates. Check

the level of all cells, and top up with distilled water

as required to the correct level. If ambient tempera-

ture is below zero, the engine should be run for a

while after topping up with distilled water, ie, there is

otherwise a risk that the battery fluid will freeze.

4. Make sure the venting holes in the cell caps are not

clogged. Refit the caps.

5. Battery terminals must be clean and well tightened.

Clean the terminals if corroded and grease them

with acid-free Vaseline.

Always ensure that the battery box is

closed and latched when driving.

When removing the battery, always

disconnect the negative cable first.

When fitting the battery, always connect the

positive cable first.

Take care of the battery after changing. The

battery contains lead which contaminates

the environment unless it is treated properly.

Before doing any electric welding on the

machine, disconnect the ground cable of

the battery and then disconnect all electric

connections to the alternator.

Fig. 20 Battery shelf

1. Knob

WARNING

WARNING

1

1

Fig. 21 Battery shelf

1. Knob

WARNING

CAUTION

WARNING

Loading...

Loading...