7CA 251/301 M251EN2

MAINTENANCE SCHEDULE

Read through the manual before carrying out any

maintenance operations. Proper care of the roller is essential

to ensure satisfactory operation.

Keep the machine clean so that any leakage, loose bolts or

loose connections can be easily detected. Make a habit of

checking around the roller and also on the ground. This is

usually the easiest way to detect any leakage at an early

stage.

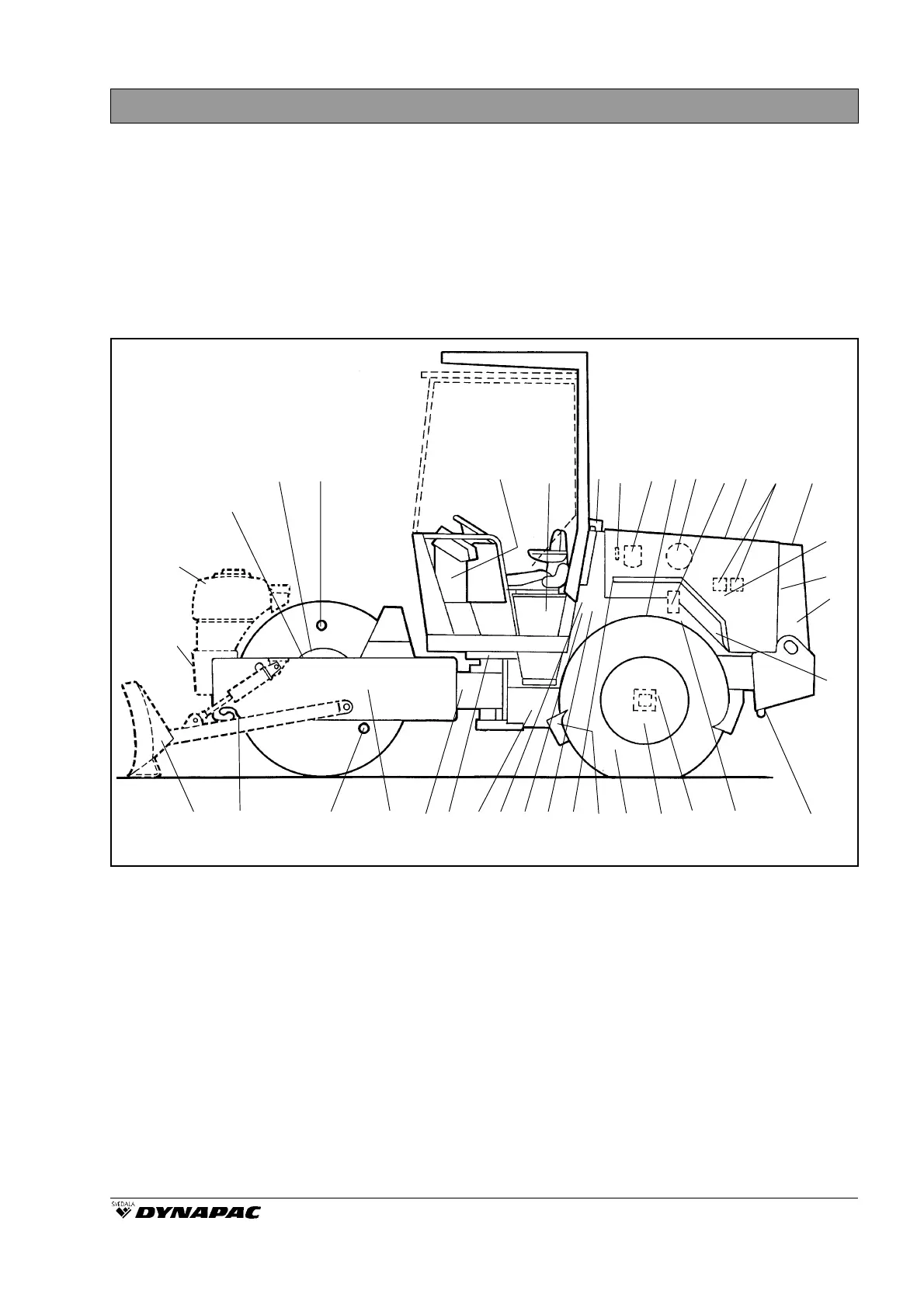

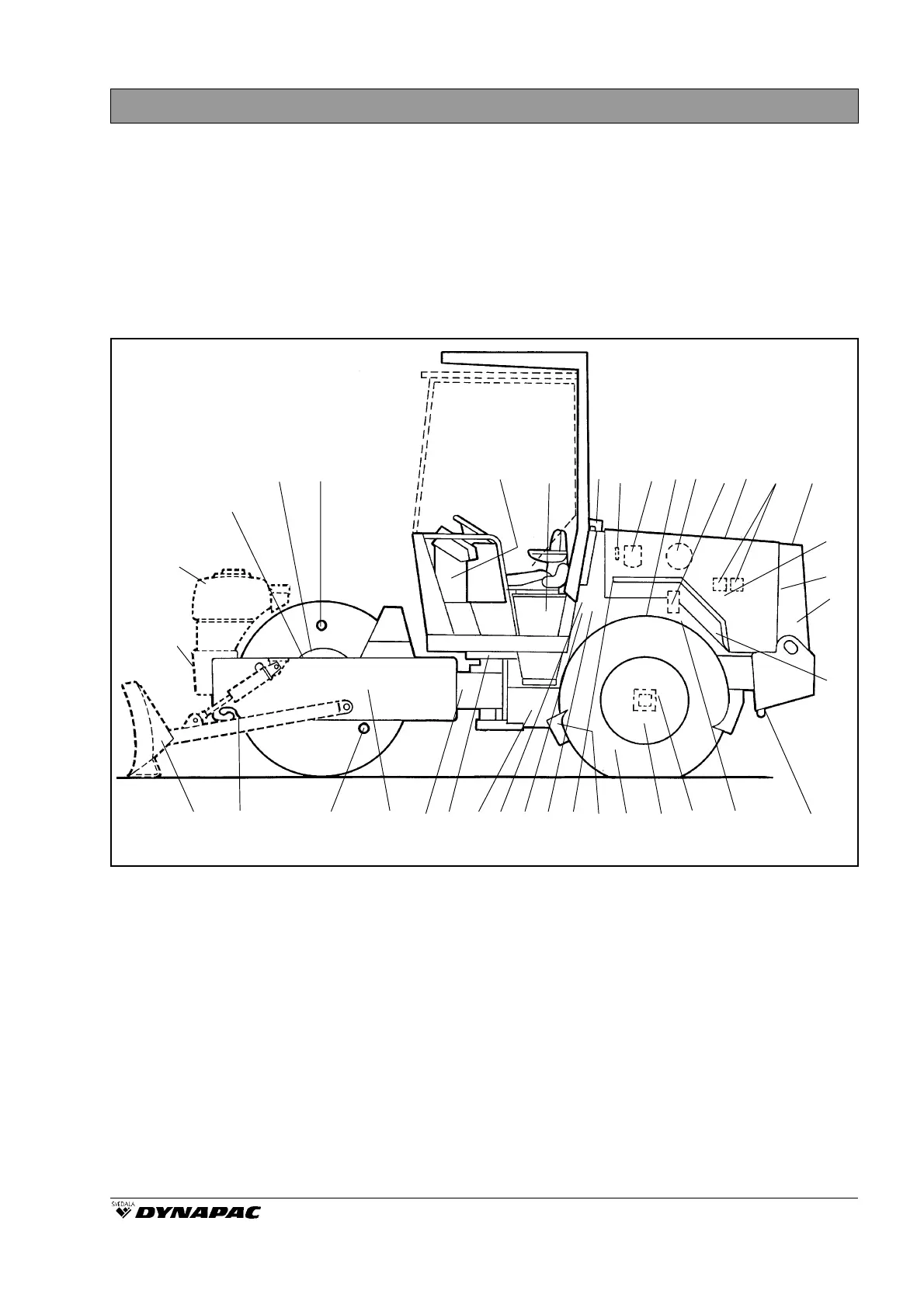

Fig. 1 Service points

1. Torque hubs (D and PD only)

2. Drum oil, filling

3. Fuse box

4. Battery

5. Hydraulic fluid, filling

6. Venting filter, hydraulic reservoir

7. Sight glass, hydraulic reservoir

8. Hydraulic fluid filter (3 off)

9. Air cleaner

10. Lubricating oil filter, engine

11. Engine hood, hinge

12. Fuel filter/Water separator, engine

13. Coolant, Cummins

14. Hydraulic fluid cooler, Cummins

15. Feed pump, diesel fuel

16. V-belt

17. Diesel fuel, filling

18. Engine suspension

19. Fuel tank, drain

20. Oil level, engine

21. Rear axle suspension

22. Rear axle, lubricating oil levels

23. Wheel nuts

24. Tire pressure

25. Scrapers (CA 251A)

26. Drain, hydraulic reservoir

27. Tyre sprinkler (CA 251A)

28. Hydraulic fluid cooler, Deutz

29. Flyweel cover, hydraulic pumps

30. Steering cylinder

31. Steering articulation

32. Rubber element, fastening bolts

33. Level plug, drum oil

34. Scraper

35. Sprinkler system (CA 251A)

36. Water tank (CA 251A)

37. Drum cassette, oil

38. Emulsion tank (CA 251A)

39. Levelling blade (optional

equipment)

40. Wind shield wash, cab (optional

equipment)

1 2 3 4,5 6 7 8 40 9 10 11 12 13,14

39 34 33 32 31 30 38 29 28 27 26 25 24 23 22,21 20 19

36

35

37

15

16

17

18

Loading...

Loading...