21

LT800 ILT800EN3

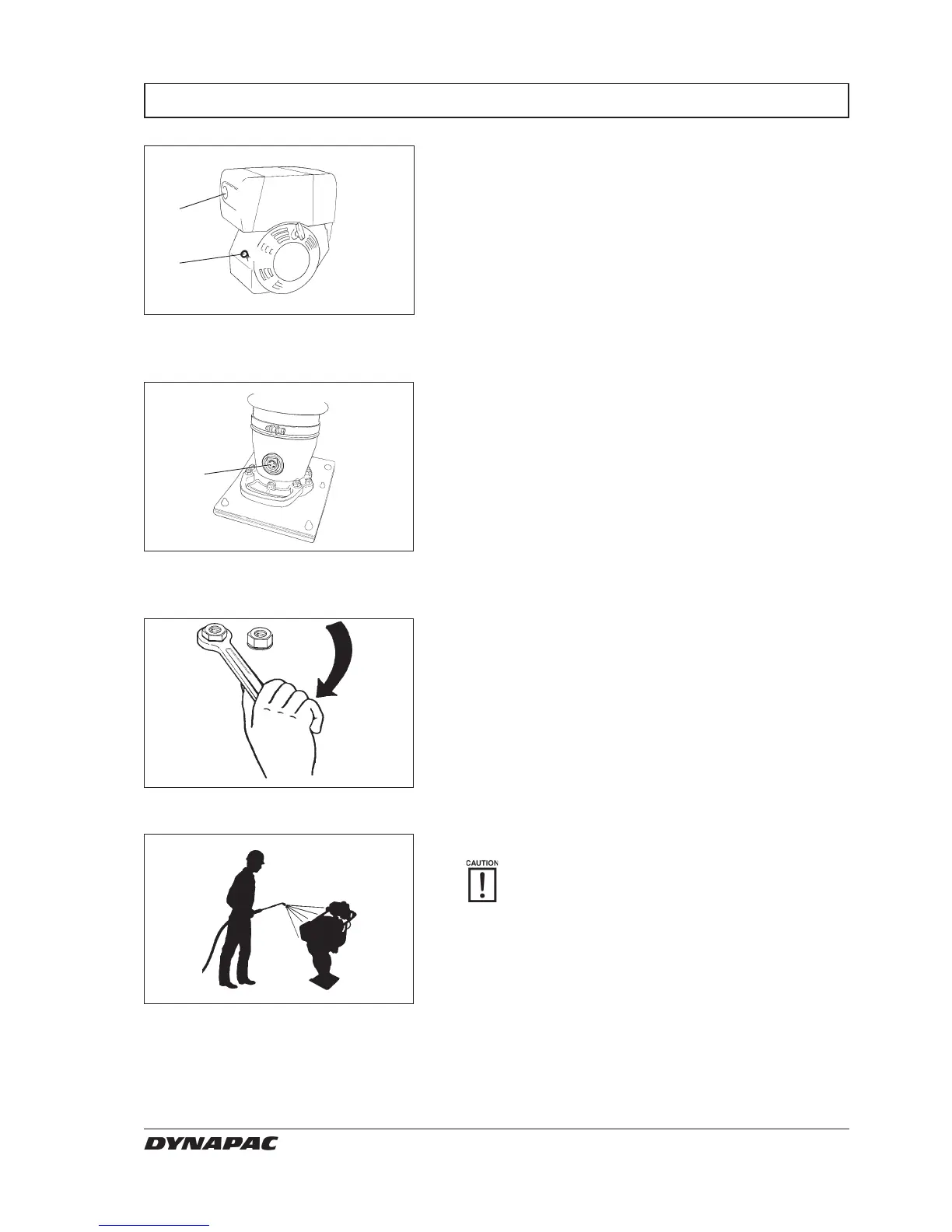

4. Check and, where necessary, tighten screws and

nuts.

5. Keep machine clean.

Never aim a water jet directly at the cap of the

fuel tank. This is especially important when

using a high-pressure jet. Put a plastic bag

over the filler cap of the fuel tank and secure

with a rubber band.

3. Check ramming system lubrication with sight glass

(1). The level should be at the middle of the sight

glass.

1. Sight glass

1

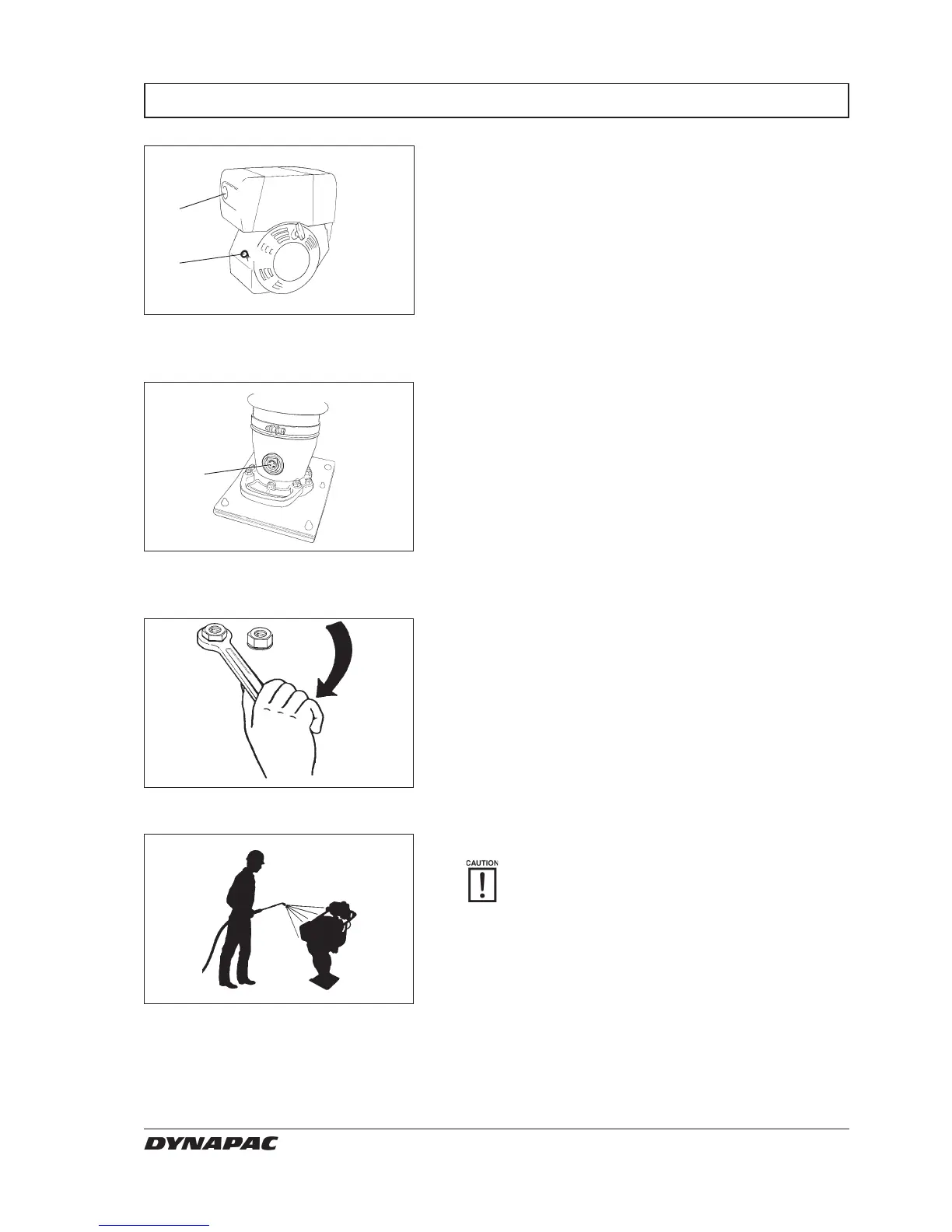

1. Check oil level (1) in the engine.

2. Check air cleaner (2).

We recommend reading the detailed engine instructions

supplied with the machine.

1. Oil dipstick

2. Air cleaner

1

2

L000197A

L000198A

L000028A

L000181A

MAINTENANCE – EVERY 10 HOURS OF OPERATION

Loading...

Loading...