ELECTRONIC SPEED CONTROL (48V)

Page F-23

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings

Continuity Check

To prevent possible inju-

ry or death resulting

from a battery explo-

sion, use an insulated wrench and remove the BL-

wire from the battery to disconnect electrical power to

vehicle.

Before attempting to perform a continuity check, turn

the key switch to ‘OFF’ and place the direction selec-

tor in neutral.

Before any electrical service is per-

formed on 48 volt model vehicles, the

Run-Tow/Maintenance switch must be placed in the ‘Tow/Mainte-

nance’ position.

If a power wire (battery, motor or controller) is disconnected for

any reason on the 48 volt model vehicle, the Run-Tow/Mainte-

nance switch must be left in the ‘Tow/Maintenance’ position for

at least 30 seconds after the circuit is restored.

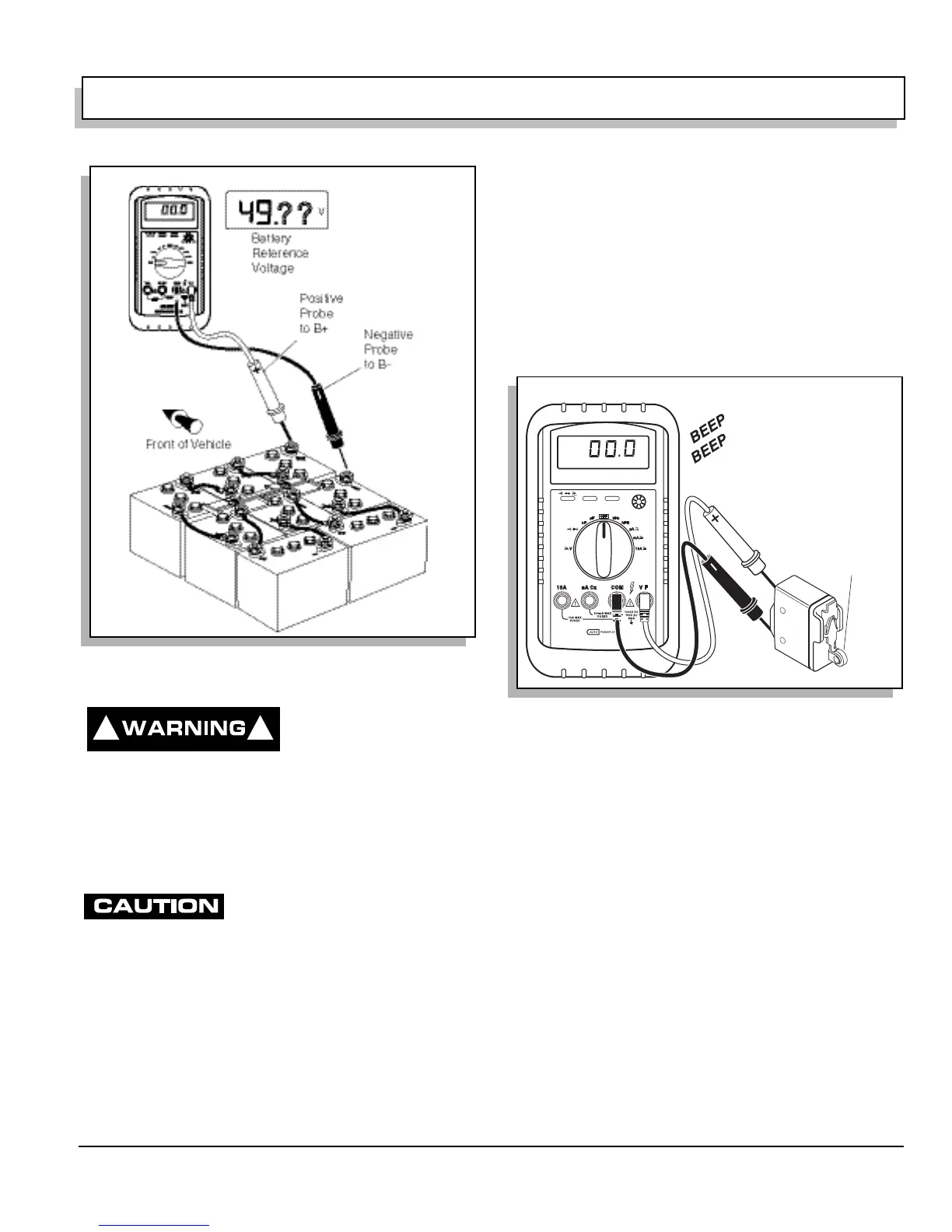

Turn the key switch to ‘OFF’ and place the direction

selector in neutral before disconnecting power by remov-

ing the BL- connection to the battery. Always use insu-

lated wrenches when working on batteries. To check

for continuity, set the DVOM to the KΩ setting and select

‘Continuity’. The meter will give an audible signal when it

detects continuity. If the meter does not have a continuity

setting, set it to KΩ, the meter will indicate “0” when it

detects continuity.

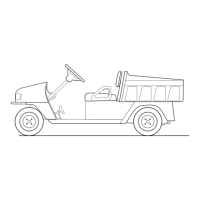

Testing a Switch for Continuity

Place one probe on one contact of the switch, place the

second probe on the second terminal of the switch (Ref

Fig. 5 on page F-23).

Actuating a normally open (NO) switch will cause the

DVOM to show “0” or give an audible indication when the

switch is operated. A normally closed (NC) switch will

cause the meter to show “0” or give an audible indication

when the probes are attached without activating switch.

The audible indicator will stop and the meter display will

indicate a value greater than “0” when the switch is acti-

vated.

The change in display or audible indicator demonstrates

that the switch is functioning.

Testing a Solenoid for Continuity

Place one probe on one of the large terminals and the

other probe on the second large terminal (Ref Fig. 6 on

page F-24). If the meter shows “0” or gives an audible

indication, the solenoid terminals are “welded” closed

and the solenoid must be replaced.

If the continuity test indicates that contacts are not

“welded” and the wiring to the solenoid coil is good, the

coil has failed and the solenoid must be replaced.

Fig. 4 Battery Reference Voltage

! !

Fig. 5 Continuity Check of Switch

Press to

activate

switch

Loading...

Loading...