Instruction Leaflet IL0102002E

Effective April 2018

Ring Main Unit Operation Instruction

10 EATON CORPORATION www.eaton.com

Figure 6-2 Basic schemes

7.1. Overall structure

The typical scheme is a one/in-two/out three-section common

enclosure RMU, including one incoming, one ring feeder and one

ring outgoing.

The layout of the typical scheme is shown in Figure 4 (RVAC-KKT).

The overall structure is composed of two major parts, the

gas-filled sealed housing part and the non-gas-filled part such as

the control compartment, cable compartment, frame, and

pressure relief channel. The high voltage circuit is within the

gas-filled sealed housing, and the mechanism compartment is on

the top front, while the pressure relief channel is on the bottom

front. Fully shielding cable terminals are used for incoming and

outgoing lines.

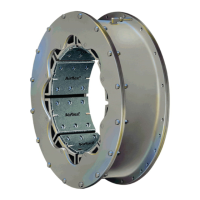

7.2.1. Sealed housing

7.2. Component structure

The sealed enclosure housing is made of high-quality stainless

steel plates, using fully enclosed welding method and SF6 gas,

with the rated pressure of 0.03 MPa. During the whole running

life, safe operations can be maintained without the need to refill

the gas. After assembling, the gas-filled housing can not be drilled

nor welded.

7.2.2. Three-position Load switch

The three-position load switch is installed inside the gas-filled

housing, with its operating mechanism installed inside the control

compartment. The three-position load switch offers closing,

opening and grounding positions. The three-position load switch is

in the opening position when the knife is in the middle position.

The three-position load switch is in the closing position and ground

position separately when the knife is in the two-limit positions.

The load switch side and the ground switch side of the

three-position load switch are equipped with clear and reliable

mechanical opening/closing indicator (see Figure 7).

Loading...

Loading...