EBARA

CORPORATION

.

3. Precautions during stop operation

1) When the pump is left underwater in stop-operating state, measure the insulation resistance of motor

intermittently. If there is no abnormality in the insulation resistance, operate the pump to prevent the

sliding section of the pump from rusting. When the pump is entered restarting, the procedure shall

conform to 6 "Operation".

2) When the pump is stored on ground, clean the pump and then store it at a dry site. (temperature of

storage: -5~40°C) On reusing the pump, follow the instructions of 5 "Installation" and 6

"Operation".

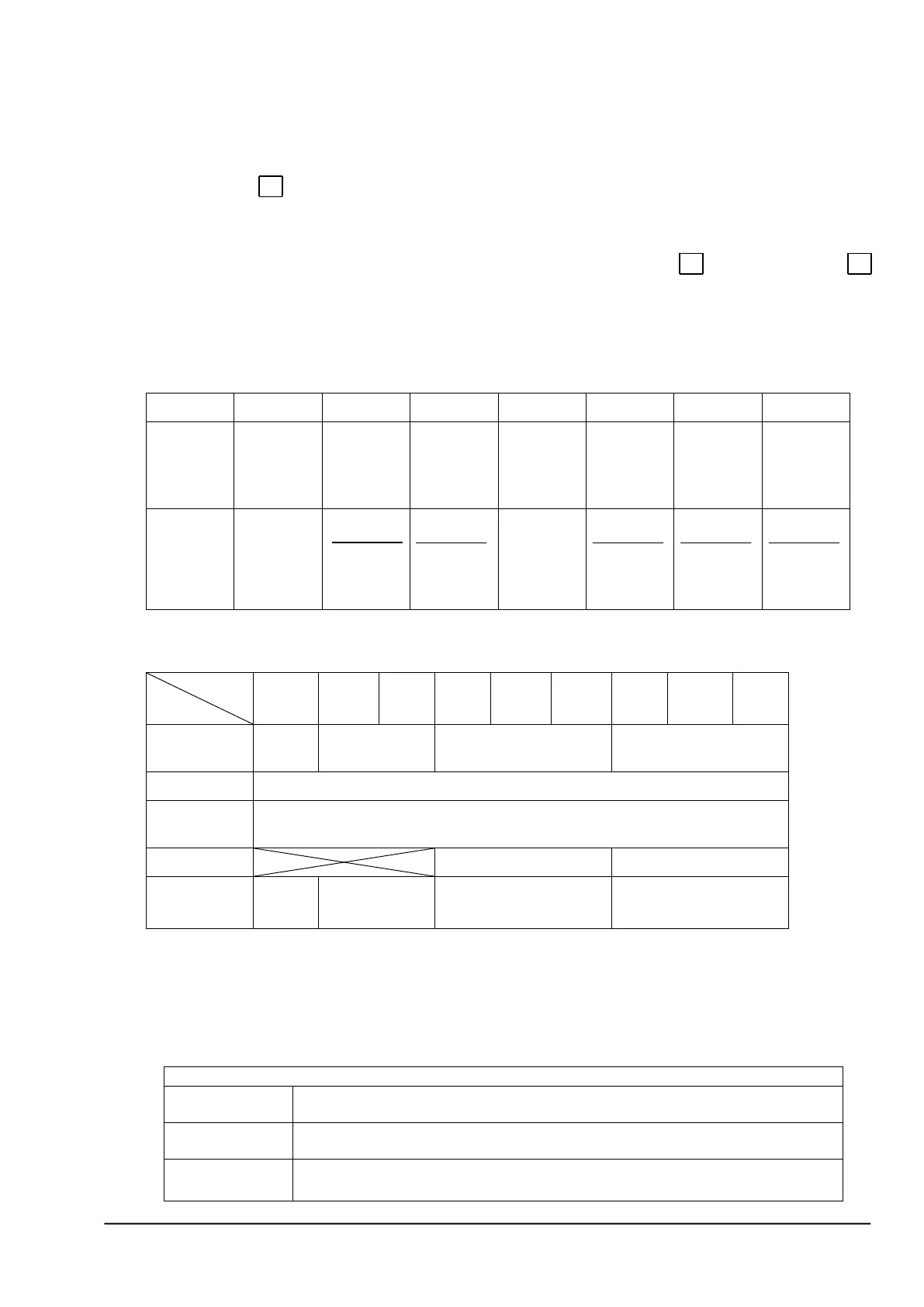

4. Consumables

1) Replace the parts when they enter the following-described condition.

Symptoms

or

approximate

period for

replacement

Oil in the

mechanical

seal

chamber

becomes

cloudy.

At every

disassembly

for

inspection.

At every oil

replacement.

Lubricant

becomes

cloudy or

blackish.

At every

disassembly

for

inspection

Every 20000

cycles of

operation

Every

100000

cycles of

operation

Expected

replacement

time

One year or

6000 hours

of total

operating

hours, either

of shorter

one.

The above-given replacement time is a standard under normal operation.

Φ11.8×Φ22(inner dia. × outer dia.) Nominal W12(SUS)

Lubricant oil

(Turbine oil)

For the quantity of oil, refer to the appearance dimensional drawing.

For detail of Model, etc. of individual parts, inquiry shall be given to the supplier or EBARA CORP.

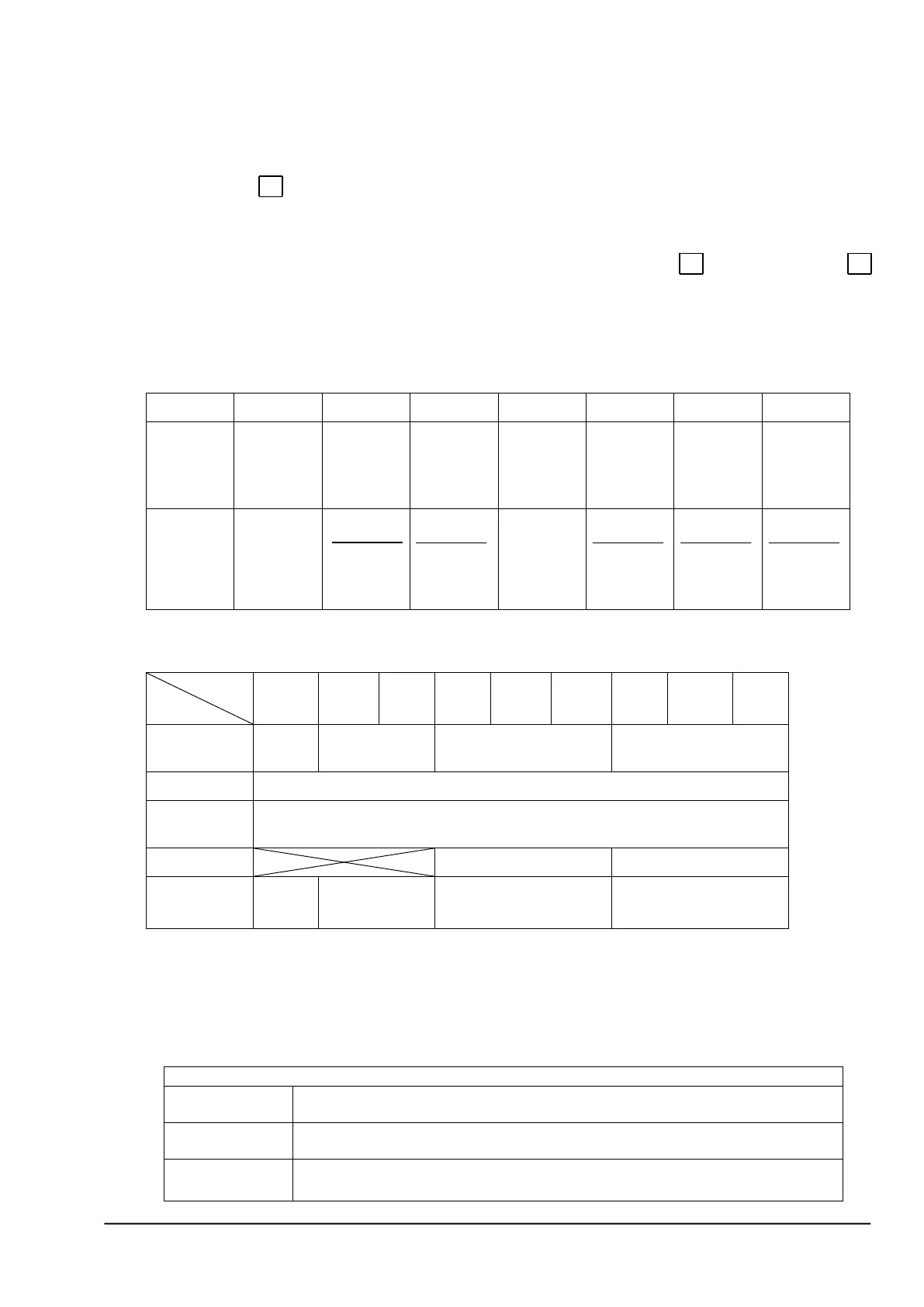

5. Action when protective device is activated

1)When thermal protector is activated:

Investigate the cause of the activation, take measures to eliminate the cause, then restart operation.

AC230V, 13A (Max)

AC200V-6mA or DC12V-10nA (Min)

Break Contact

(Normal: on, At temp. rise: OFF)

400V:2 cores YZW, Cab-tyre Cable 1mm

2.

Blue Brown, (non-polarity)

200V:2 cores 2PNCT, Cab-tyre Cable 1.25mm

2.

White Black,(non-polarity)

Loading...

Loading...