EBARA

CORPORATION

.

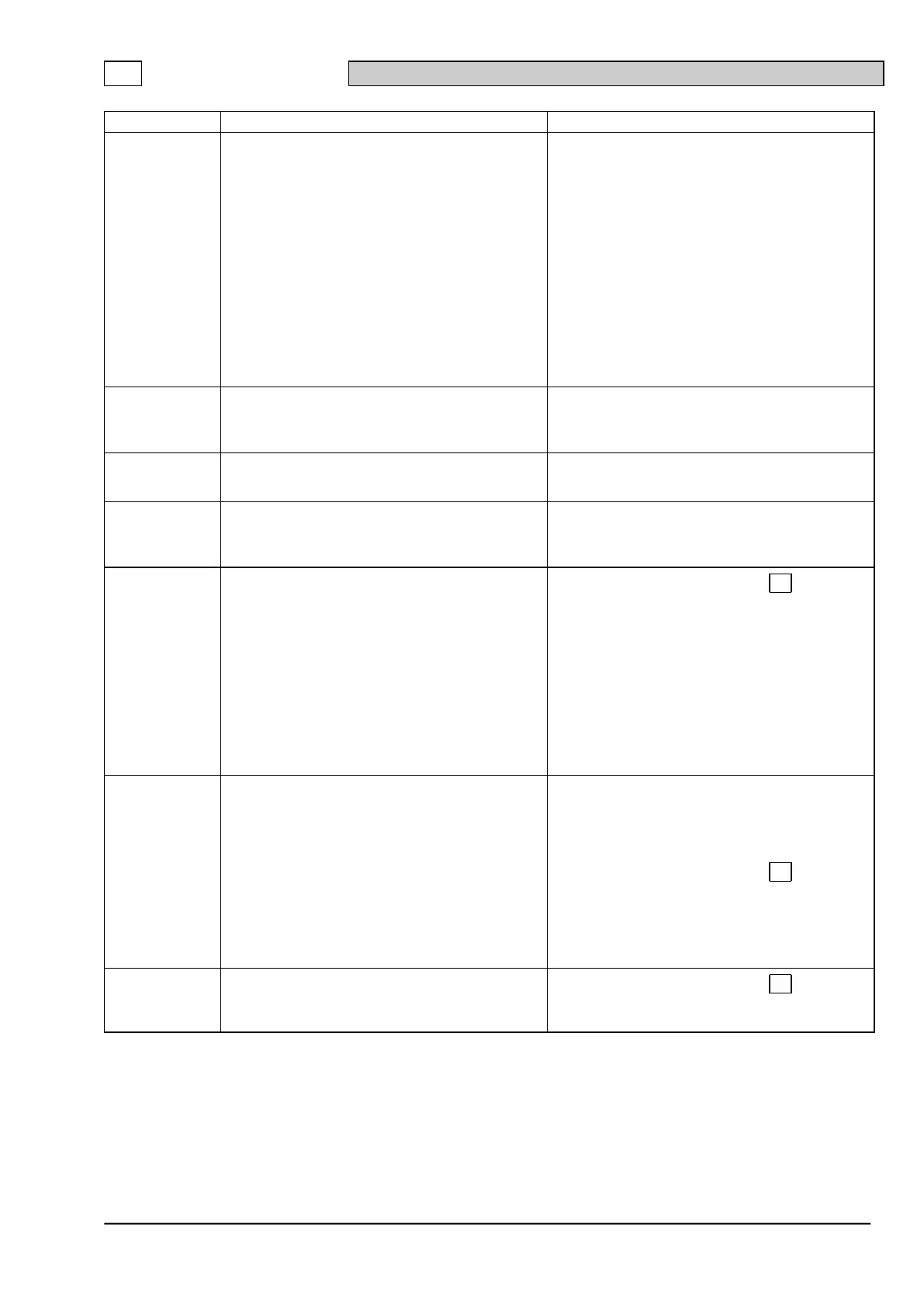

Pump does not

start, or starts

but immediately

stops.

- Float movement is obstructed.

- Power failure has occurred.

- Excessive imbalance in power supply

voltage.

- Excessive voltage drop.

- Phase interruption.

- Faulty connection in power circuits.

- Error in control circuit wiring.

- Blown fuse.

- Faulty magnet switch.

- Level switches are malfunctioning or faulty.

- Electrical leakage breaker activated.

- Foreign matter trapped in pump.

- Motor burned out.

- Motor bearings worn out.

- Mechanical seal locked.

- Remove the obstructions.

- Contact electric power company.

- Contact electric power company.

- Contact electric power company.

- Check wiring connections and magnetic switch.

- Check power circuits.

- Correct wiring error.

- Replace with fuse of correct capacity.

- Replace with item of correct specification.

- Replace or repair.

- Perform repair at location of leakage.

- Eliminate foreign matter.

- Replace or repair.

- Replace or repair.

- Replace or repair.

Operates, but

stops after a

while.

- Prolonged dry operation has activated automatic

cut-off function.

- High liquid temperature has activated automatic

cut-off function.

- Raise stop water level.

- Lower liquid temperature.

Thermal

protector

activates.

- Liquid temperature is high.

- Pump is run in air for prolong time.

- Overcurrent

- Lower liquid temperature.

- Raise stop water level.

- Refer to the column for overcurrent.

Flood-sensing

device

activates.

- Mechanical seal leaks.

- No longer serviceable.

- Replace the mechanical seal.

(Liquid quality and operation conditions need to

be reviewed.)

- Replace the mechanical seal.

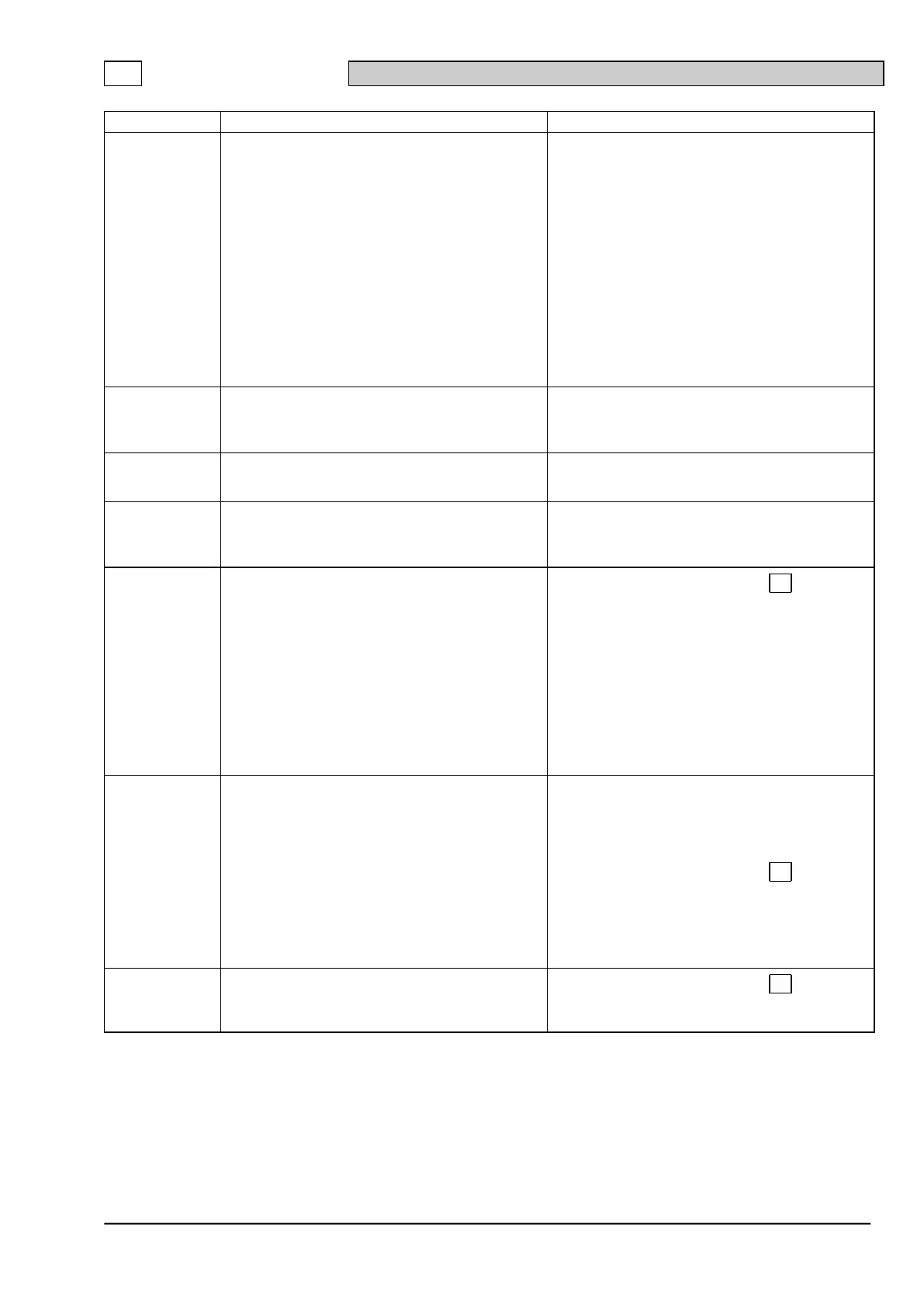

Pumping not

effected, or

insufficient

pumping

capacity.

- Pump running in reverse rotation.

- Gate valve is damaged.

- Excessive voltage drop.

- 60 Hz pump used with 50 Hz.

- Discharge head too high.

- Piping loss too large.

- Water level too low, air drawn in.

- Discharge pipe leaking.

- Discharge pipe clogged.

- Foreign matter in suction inlet.

- Pump interior clogged with foreign matter.

- Impeller(s) worn out.

- Obtain regular rotation (Refer to 6 -2. (2)).

- Inspect and repair.

- Contac electric power company.

- See nameplate for frequency.

- Rethink system plan.

- Rethink system plan.

- Raise water level or lower pump’s position.

- Inspect and repair.

- Unclog pipe.

- Remove foreign matter.

- Disassemble pump and eliminate foreign matter.

- Replace impeller(s).

- Excessive voltage imbalance between supply

phases.

- Excessive voltage drop.

- Phase interruption.

- 50 Hz pump used with 60 Hz.

- Pump running in reverse rotation.

- Head too low. Water flow rate too high.

- Foreign matter trapped in pump.

- Motor bearing worn out.

- Contact electric power company.

- Contact electric power company.

- Check connections and magnet switch.

- See nameplate for frequency.

- Obtain regular rotation (Refer to 6 -2. (2)).

- Turn down the gate valve. If there is no gate

valve, replace the pump with the lower head

pump.

- Disassemble pump and eliminate foreign matter.

- Replace or repair.

Vibration

excessive or

noise.

- Pump running in reverse rotation.

- Foreign matter trapped in pump.

- Piping resonating.

- Obtain regular rotation (Refer to 6 -2. (2)).

- Disassemble pump and eliminate foreign matter.

- Make improvements in piping to stop resonance.

Loading...

Loading...