4

EN

7. SPECIFICATIONS

7.1. PUMP SPECIFICATIONS

U.M. EVMS EVM

Max. temperature of liquid

pumped

°C

depends on the mechanical seal

(see Data Book)

Max. qty. / max. size of solids

Ppm/

mm

50 /

0.1 ÷ 0.25

Max. working pressure MPa 1.6 ÷ 2.5 1.6 ÷ 3.0

Delivery diameter

* G 1” ÷ Ø 100mm

Suction diameter

* = threading according to ISO 228

7.2. MOTOR SPECIFICATIONS

U.M. EVMS EVM

TYPE T.E.F.C.

IP rating IP 55

Max. starts

per hour

N.°

100

60

30

15

8

kW

≤ 0.55

0.75÷3.0

4÷9.2

11÷22

30÷37

Insulation class and

temperature rise

F

(classe B for temperature rise)

Type of duty Continuous S1

Ratings See motor rating plate

This list shows specication of Ebara motors. In case of using other

motors, please see nameplate of motors and check the motor

manufacturer’s specication.

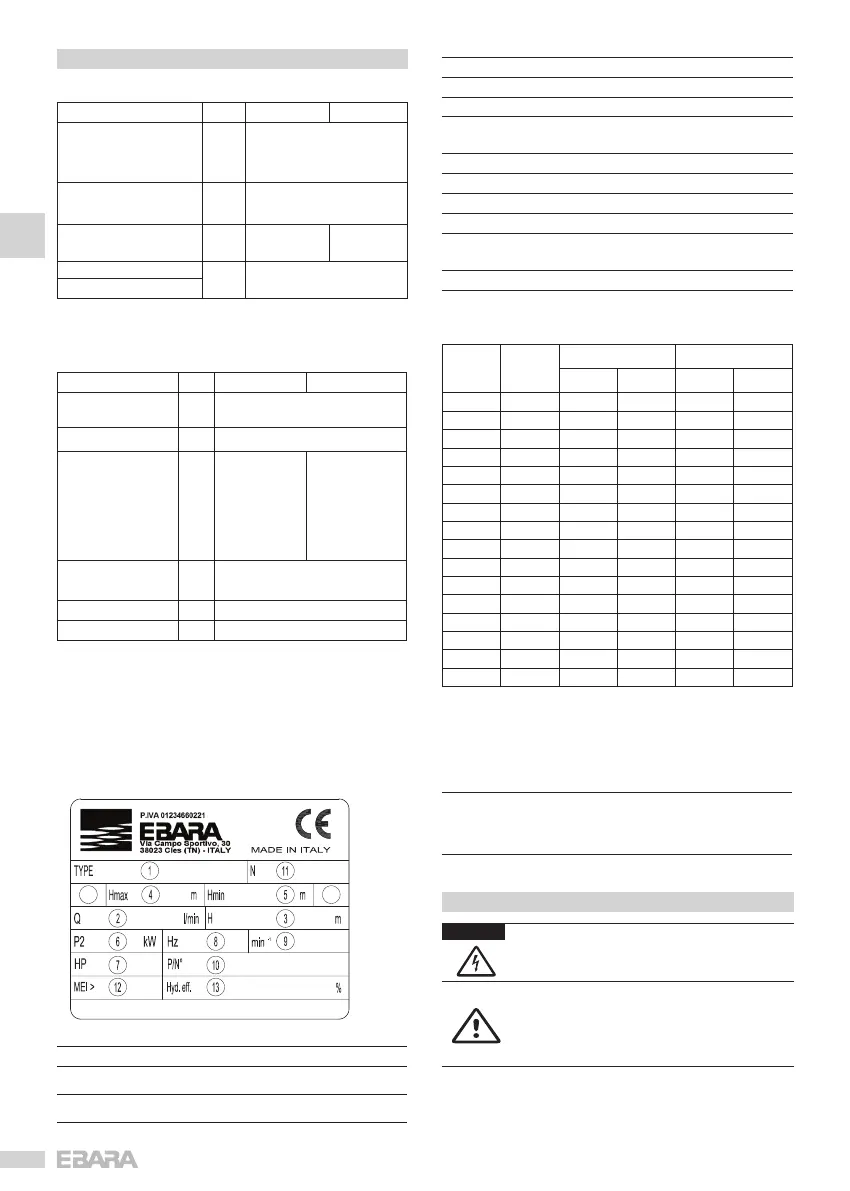

7.3. PUMP RATING PLATE

The nameplate is an aluminium label applied to the pump which bears its

technical specications.

Relevant numbers:

1) “TYPE” Pump model

2) “Q” Indicates upper and lower ow rate limits

3) “H”

Indicates head limits corresponding to minimum and

maximum ow rate

4) “Hmax” Maximum head

5) “Hmin” Minimum head

6) “P2” Rated power of the motor (output at shaft)

7) “HP”

Rated power of the motor expressed in HP (Horse

Power)

8) “Hz” Frequency

9) “min-1” Speed of rotation

10) “P/N°” Pump item number

11) “N” Material code

12) “MEI” Index of the pump’s quality in relation to its efciency

13) “Hyd. Eff. ” Hydraulic efciency of the pump

7.4. INFORMATION ON AIRBORNE NOISE

Power

[Kw]

Motor

size

50 Hz 60 Hz

LpA [dB]* LwA [dB]** LpA [dB]* LwA [dB]**

0.37 71 <70 – <70 –

0.55 71 <70 – <70 –

0.75 80 52 – 57 –

1.1 80 52 – 57 –

1.5 90 60 – 65 –

2.2 90 60 – 65 –

3 100 62 – 67 77

4 112 66 – 71 81

5.5 132 68 78 73 84

7.5 132 68 78 73 84

11 160 73 83 78 89

15 160 M 74 84 79 90

18.5 160 L 74 84 79 90

22 180 M 77 89 82 93

30 200 L 78 89 83 94

37 200 L 78 89 83 94

The table gives maximum sound emission values for motor-driven pumps.

* Sound pressure level - Mean value of measurements taken one metre

from the pump. Tolerance ± 2.5 dB.

** Sound power level. Tolerance ± 2.5 dB.

THE MANUFACTURER RESERVES THE RIGHT TO AMEND TECHNI-

CAL DATA FOR THE PURPOSE OF PRODUCT IMPROVEMENTS AND

UPDATING.

8. PREPARING FOR USE

WARNING!

Installationmustbecarriedoutbyaqualiedengineer.

Free the pump from the packaging and lift it and lower it

with suitable lifting gear in compliance with safety rules.

Note that the motor’s lifting hooks are not suitable for

lifting the motor-driven pump.

8.1 COUPLING TO THE MOTOR

The motors to be coupled to the EVM pumps must meet IEC standards and

must have the preload spring positioned as illustrated:

Loading...

Loading...