16 X7502308206

©7/2015 ECHO Inc.

OPERATION PPF-225

Saw Chain Tension Adjustment

Always disconnect spark plug wire before servicing cutting

attachment. Wear gloves when handling saw chain,

otherwise serious personal injury may result.

To Adjust Saw Chain Tension

1. Move stop switch to STOP position.

2. Disconnect spark plug lead.

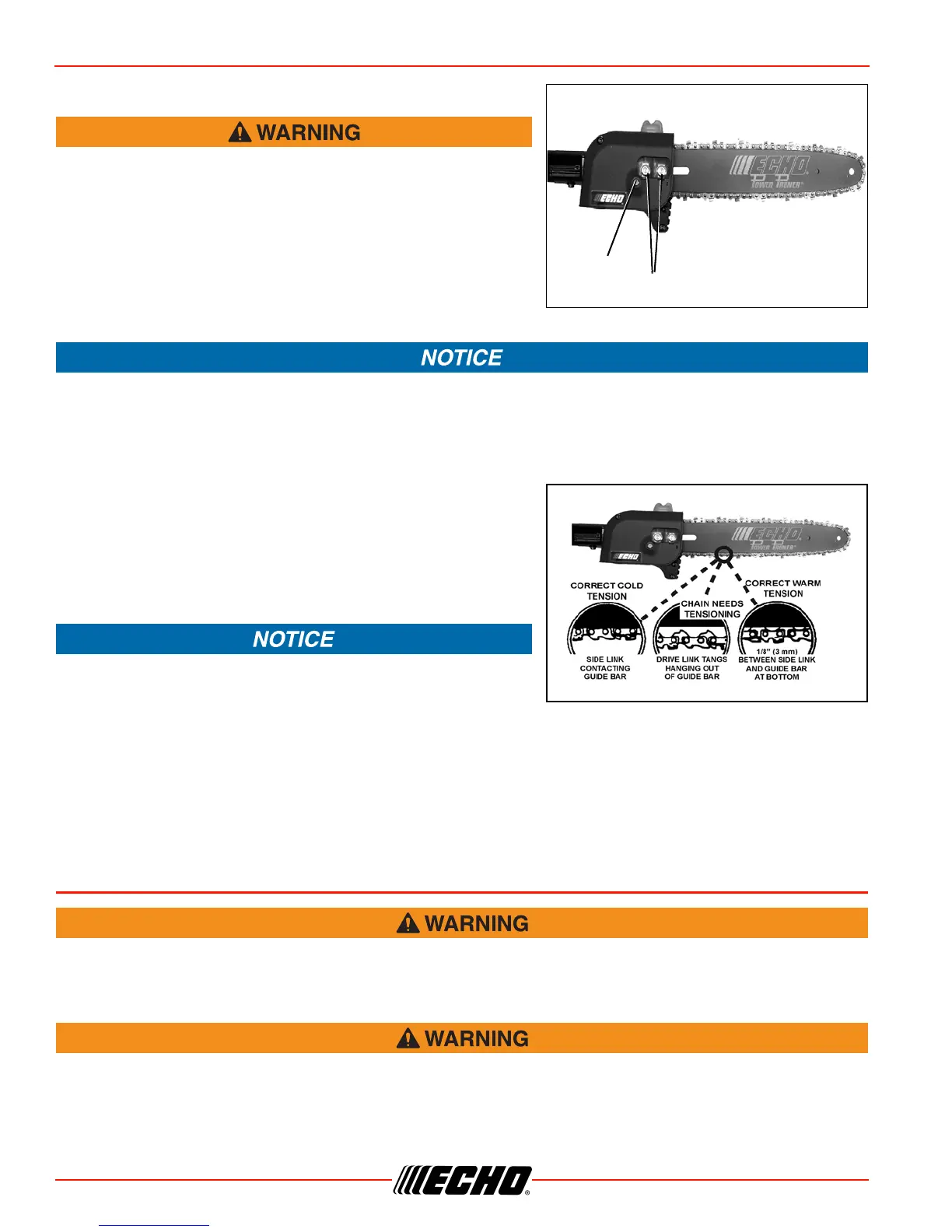

3. Loosen two guide bar nuts (A) until finger tight.

Always loosen guide bar nuts before turning the chain tension adjuster, otherwise the clutch cover and

tensioner will be damaged.

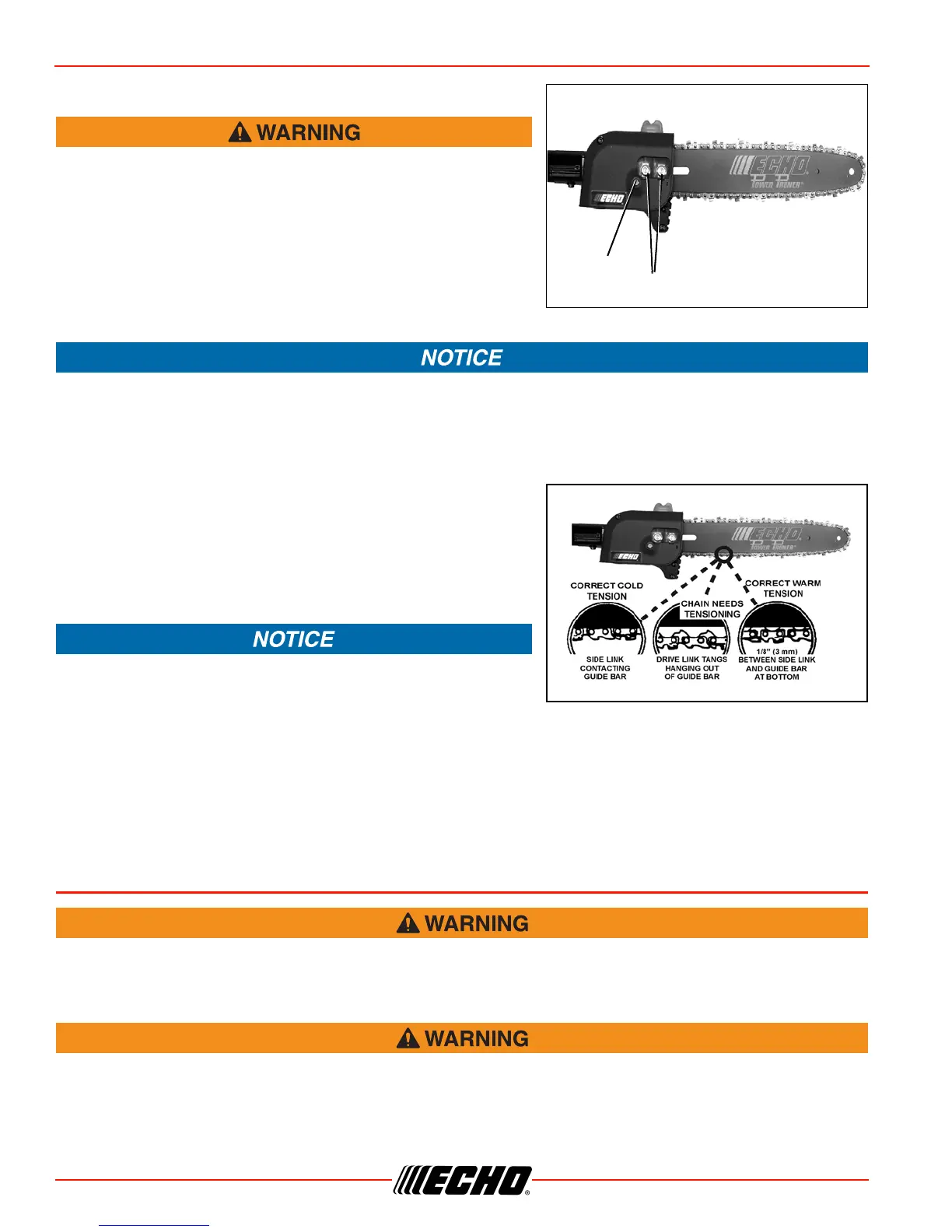

4. Hold the bar nose up, and turn the adjuster screw (B) clockwise until the chain fits snugly against the

underside of the bar, as shown. Cold Chain Only - turn adjuster screw CW an additional 1/8 - 1/4 turn.

5. Tighten both guide bar nuts with nose held up. Tighten rear

nut first.

6. Pull the chain around the guide bar by hand. Reduce the

chain tension if you feel tight spots.

7. When chain is properly tensioned, tighten guide bar nuts

securely.

Tighten guide bar nuts to 8 - 9 N•m (71 - 80 in. lbs.) DO NOT

over-tighten nuts. Damage may result

8. Keep chain properly tensioned at all times.

Note: All chains require frequent adjustment.

9. Connect spark plug lead.

OPERATION

Moving parts can amputate fingers or cause severe injuries. Keep hands, clothing and loose objects

away from all openings. Always stop engine, disconnect spark plug, and make sure all moving parts

have come to a complete stop before removing obstructions, clearing debris, or servicing unit.

Operation of this equipment may create sparks that can start fires. This unit is equipped with a spark

arrestor to prevent discharge of hot particles from the engine. Metal cutters can create sparks if the

cutter strikes rocks, metal, or other hard objects. Contact local fire authorities for laws or

regulations regarding fire prevention requirements.

Loading...

Loading...