Part 5.5 Further Venting Options: PVC/CPVC/Polypro single pipe

REQUIREMENTS FOR INSTALLATION OF SINGLE PIPE VENTING ON ECO KING BOILERS IN CANADA

Venting PART 1 Installations must be made with ANY vent pipe system certified to ULC-S636. Examples are, M&G

Duravent, Cox Geelen and Centrotherm polypropylene and IPEX 636 PVC/CPVC. They are approved vent

manufacturers in Canada supplying vent material listed to ULC-S636, but are not exclusive. Any PVC/CPVC and PP

manufacturer approved to ULC S-636 can be used. Please see Table 1 below for an outline.

Table 1 Approved exhaust vent material on Eco King Boilers

Standards for installation in:

ANSI / ASTM D1785 & D2665

**When using PVC/CPVC for exhaust venting, an appliance adapter transitioning from PP to CPVC acts as

the starter pipe (field supplied).**

**When transitioning to 2” venting, a 3” to 2” reducing adapter should be used**

**For installations using PVC vent, the first seven (7) equivalent feet of vent must be PP or CPVC**

NOTE: See Part 3 for PP vent instructions and Part 5 on PVC/CPVC venting

NOTE: Eco King Boilers have a high temp flue gas protection switch

Venting PART 2 Air intake must be brought into the boiler from outside, with one exception outlined in part 4 of this

addendum, see page 4. Approved materials for air intake are listed in Table 2 below:

Table 2 Approved air intake material for Eco King Boilers

Standards for installation in:

Venting PART 3 The use of single pipe Eco King (M&G) polypropylene or any polypropylene venting rated to ULC

S-636 is now available to be used with Eco King Boilers. No special adapter needed. Please review the following

instructions:

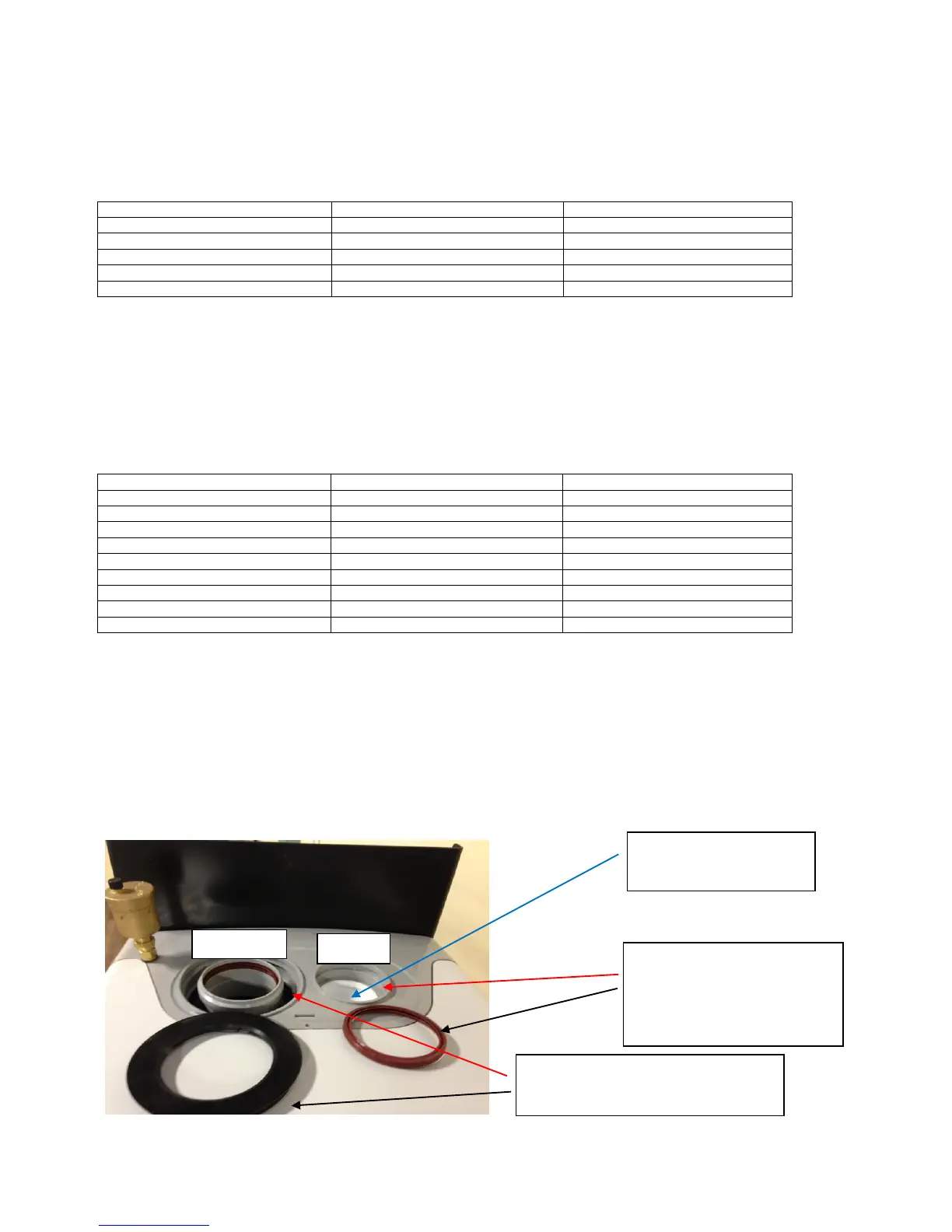

It is possible though to use a two pipe system (one for intake and one for exhaust) by following these steps:

1) A black O-ring seal (see figure 1) on the concentric air intake portion must be used to block air intake (see

figure 3). This black O ring is supplied with boiler. It is placed with the installation manuals in a plastic bag

2) Then the white cap on the separate single pipe air intake must be removed from the boiler (see figure 1)

3) Add the supplied O-Ring seal, which comes in a plastic bag with the install manuals (see figure 2)

4) Now the boiler is ready to be used in a two pipe system. Just connect any two 3” (80mm) polypropylene

fittings to the exhaust and intake. Look at Figure 4 to see how the two pipes system will look

32

O-Ring seal to cover air intake on

concentric opening. Insert where red

arrow points (see figure 3)

O ring seal for air intake when

using two pipes. To be placed

where red arrow points (see

figure 2)

Remove white cap to open

air intake inlet

Loading...

Loading...