▪ We recommend the use of a foreline vacuum isolaon valve to allow the pump to

warm up before pumping condensable vapours or if a vacuum needs to be

maintained when the pump is not running.

▪ Avoid high levels of heat input to the pump from the process gases, otherwise the

pump may overheat and seize, and cause the motor thermal overload device to

open.

▪ If using the pump in a high ambient temperature with a high gas throughput, the

temperature of the pump body may exceed 70 °C (158 °F). We recommend the use

of addional guarding to prevent contact with hot surfaces under these condions.

▪

Make sure that the exhaust pipeline cannot become blocked. If an outlet-isolaon

valve is ed, make sure the pump cannot be operated with the valve closed.

▪

Provide for a purge of inert gas when the pumping system is shut down, to dilute

dangerous gases to safe concentraons. A suitable gas-ballast control valve for

introducon of purge gas into the pump is available as an accessory (refer to

Solenoid operated gas-ballast control valve on page 38).

Contact our applicaon team for further advice on diluon requirements if required.

4.3 Unpack and inspect

Remove all packing materials and protecve covers and check the pump. If the pump is

damaged, nofy your supplier and the carrier in wring within three days, state the Item

Number of the pump together with your order number and your supplier's invoice

number. Retain all packing materials for inspecon. Do not use the pump if it is

damaged.

Check that your package contains the items listed in Table: Checklist of items on page 18.

If any of these items is missing, nofy your supplier within three days.

If the pump is not to be used immediately, replace the protecve covers. Store the pump

in suitable condions, as described in Storage on page 34.

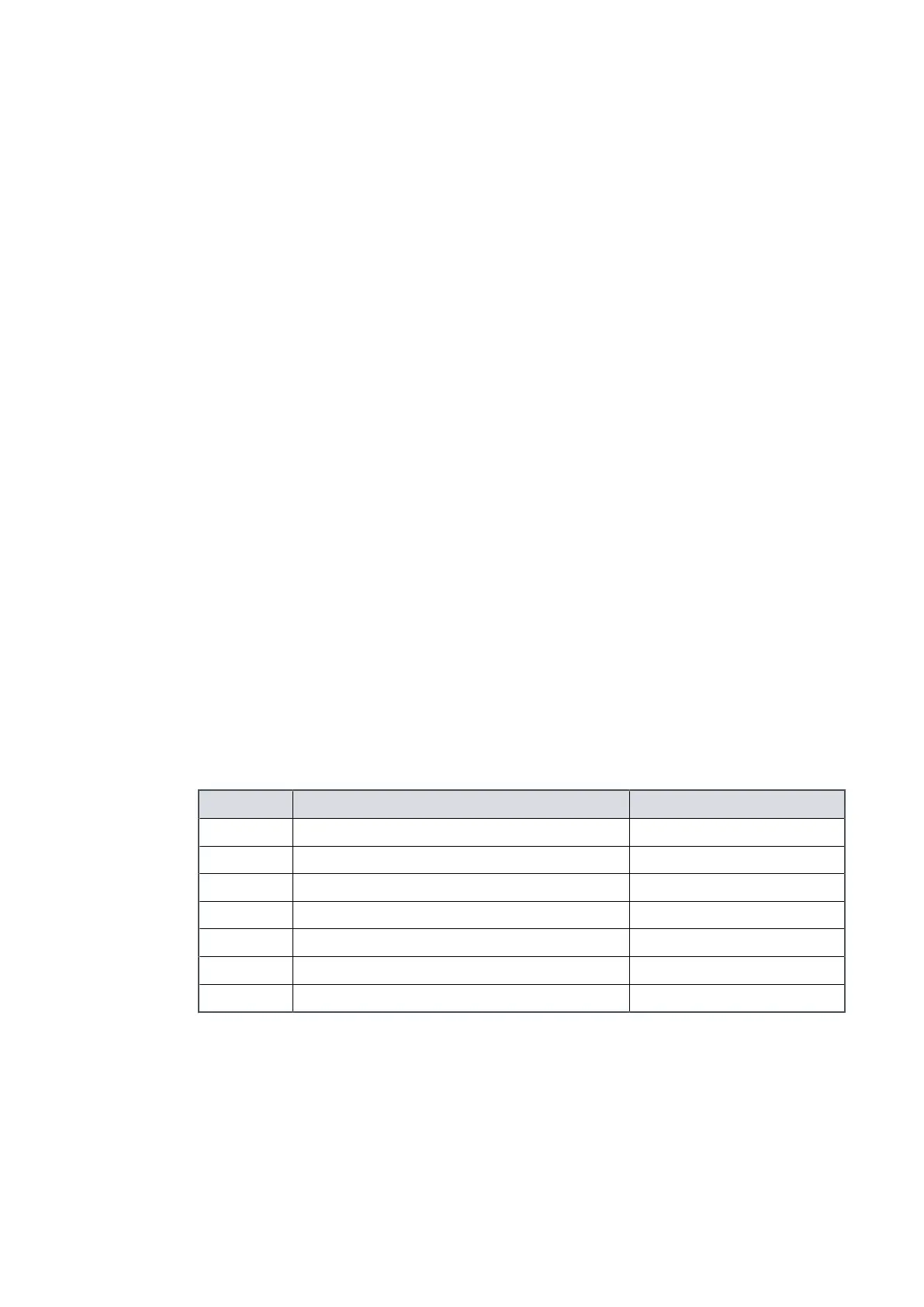

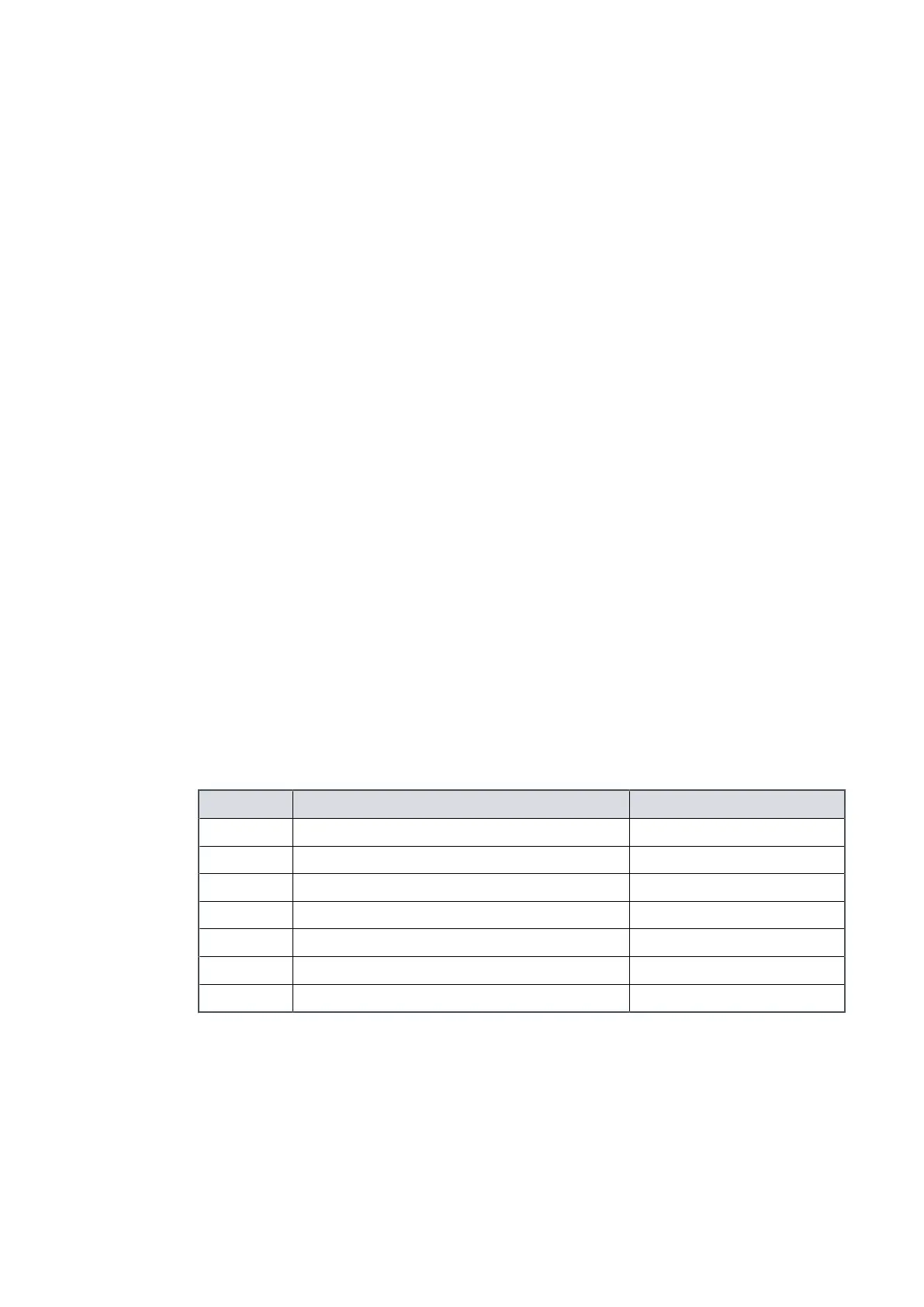

Table 8

Checklist of items

Quanty

Descripon

Check (ü)

1 Rotary vacuum pump

r

Fing pack containing the following:

1 Hexagon wrench, 4 mm

r

1 Hexagon wrench, 6 mm

r

1 NW10 centring ring

r

1 O-ring for centring

r

1 O-ring for outlet port

r

4.4 Locate the pump

The pump can be either free-standing on its baseplate which is ed with rubber pads,

xed by four xing bolt holes in the baseplate, or used with vibraon isolators. For the

locaon of xing holes in the baseplate, refer to Figure: Dimensions (mm) on page 14.

Provide a rm, level plaorm for the pump. Locate the pump so that the oil level

Page 18

A37132880_F - Installaon

Loading...

Loading...