STP-301/451 Series Instruction Manual

11-12

Troubleshooting

11.3.5 Overhaul

The recommended maintenance intervals for different process applications are tabulated

below:

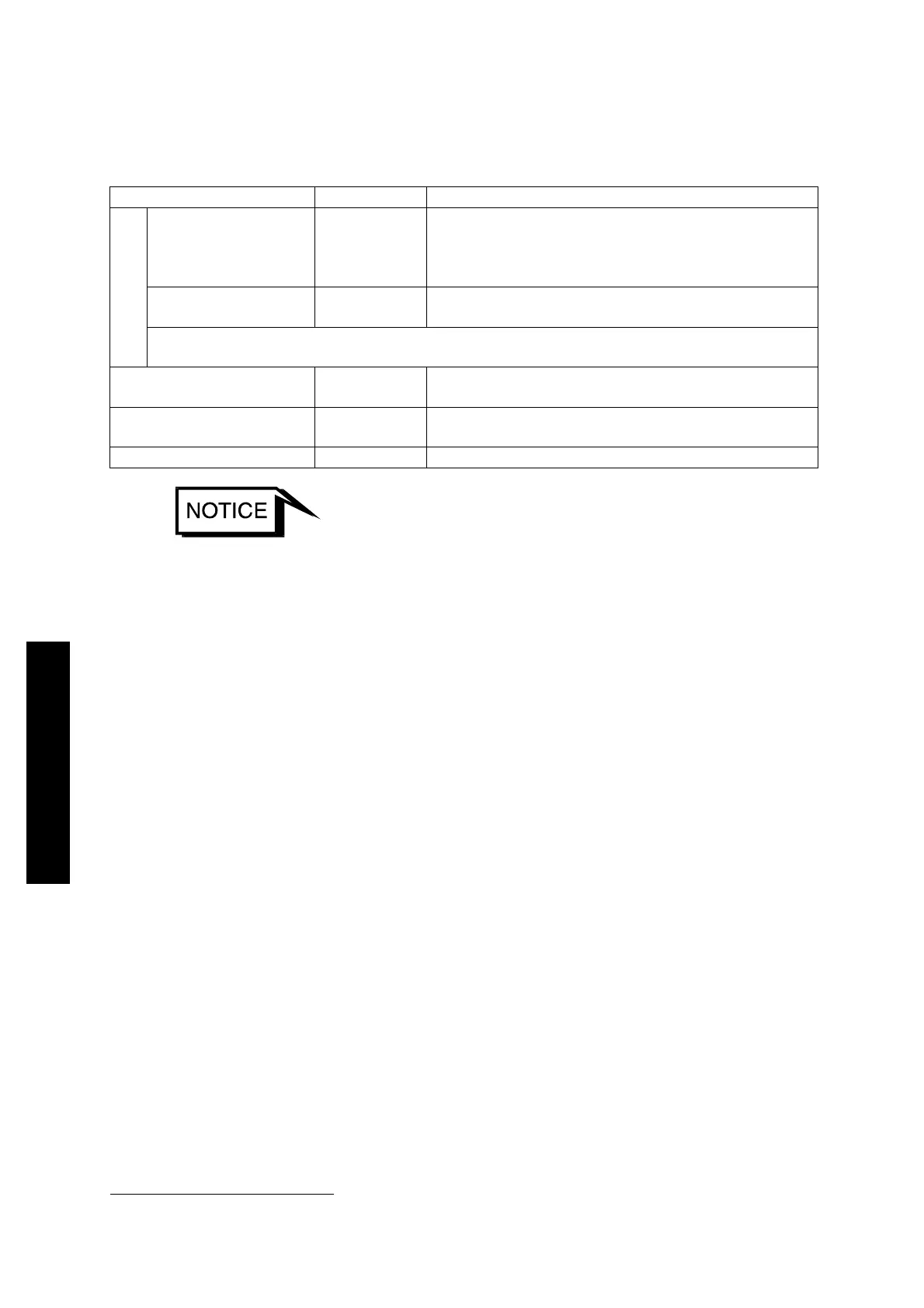

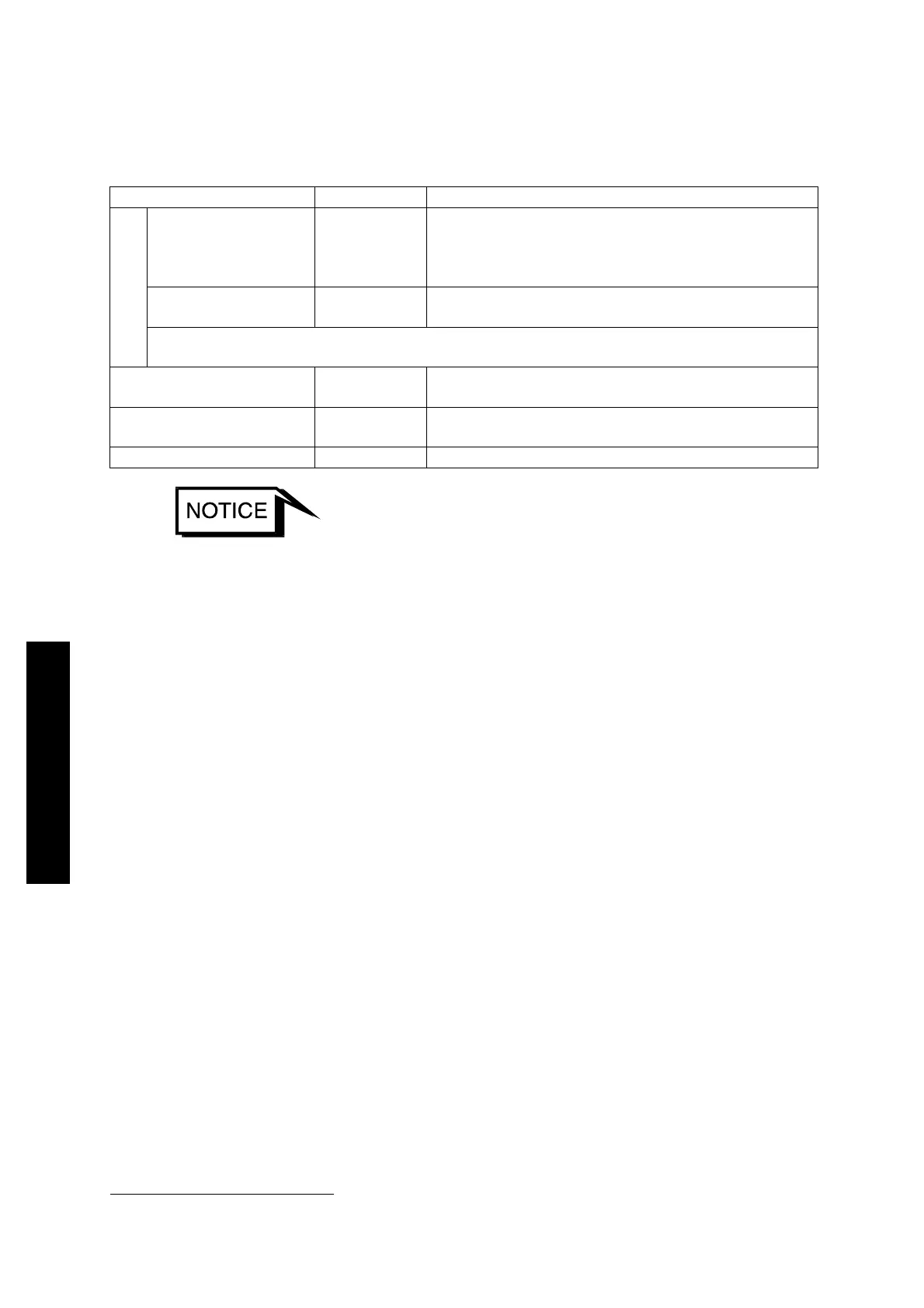

Process Period Remarks

Metal Etch 1 year Ensure that TMS (Temperature Management

System) is fitted and operational to prevent

accumulation of by-product deposition in the

pump.

Other Etch

Processes

2 years

Etching

*1

It is recommended to change the pump rotor after 5 years due to accumulated wear of

the protective plating material

Other semiconductor

process

2 years Processes resulting in accumulation of deposits in

the pump will require more frequent service.

Clean applications

(Only vacuum pumping)

5 years

Other use (2 years) Dependent on application, contact Edwards.

◇ The touch down bearing inside the STP pump will be worn out after a number of full

speed touch downs.

The costs of replacing parts that need to be replaced because of deterioration or abrasion will

be at your own charge.

When overhaul of the STP pump or the STP control unit is needed, contact Service office.

*1

“Etching” includes semiconductor etching and LCD etching.

Loading...

Loading...