EASZ-2 Manual v1.12 - 12.2.2018 Page 25 / 30

7.5. Two-Point Calibration Procedure

This is the recommend form of on-site calibration to ensure that your units are set to a higher accuracy.

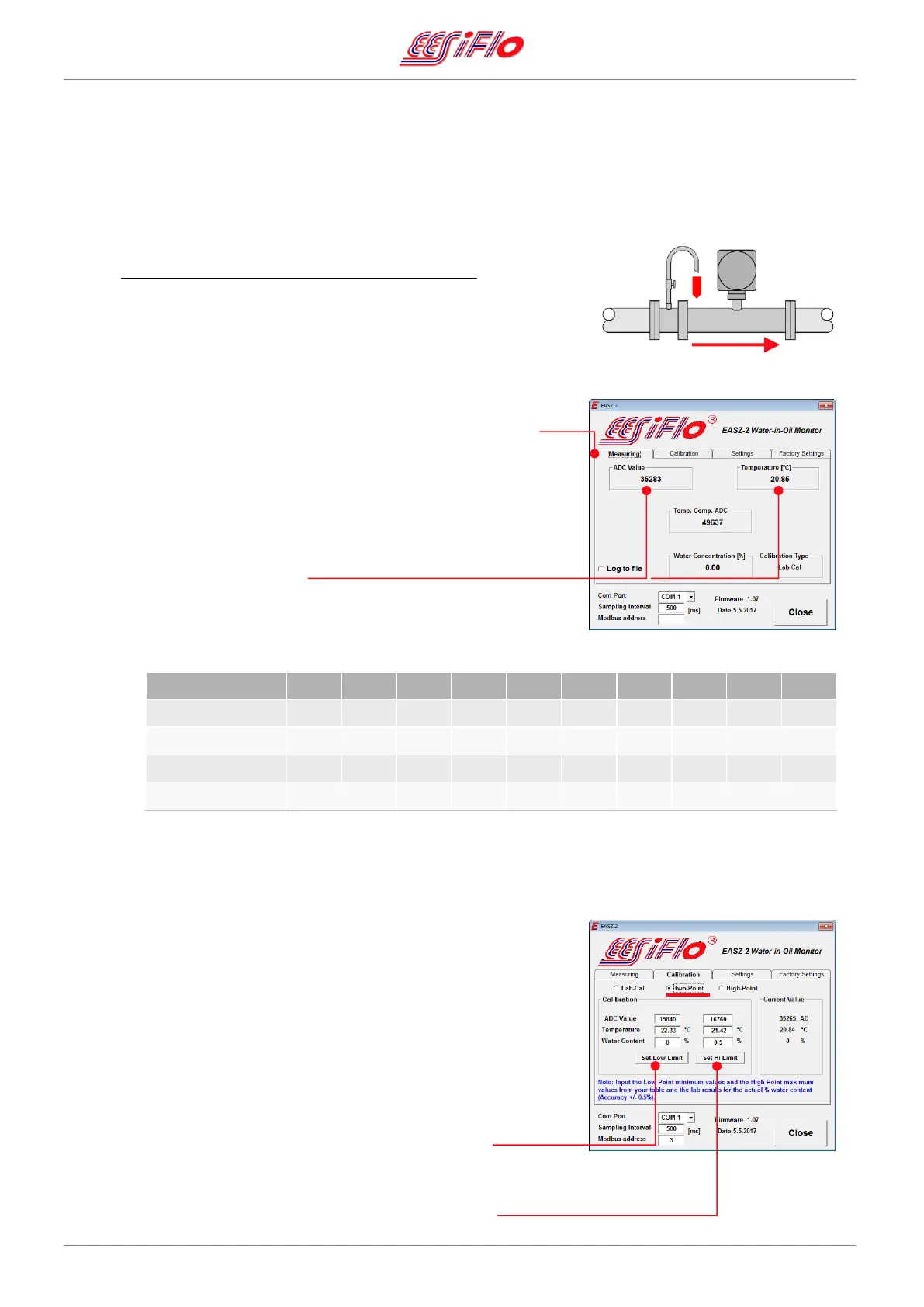

If this calibration is performed correctly the accuracy of the readings is ± 0.1%.

Should a higher accuracy of ± 0.05% be required it is necessary to use the factory calibration service from

an EESIFLO authorized service centre.

To calibrate the unit correctly follow the instructions:

1) Ensure that the pipeline is in operation and flowing full of

clean oil of the type and grade required without any air

bubbles or foreign particles.

2) Connect a computer to the EASZ-2 with an original

USB-RS or USB-CL Com Cable.

3) Start the EASZ-2 software and click the “Measuring” tab.

4) Take a sample of the oil from the sampling point just in front

of the EASZ-2 unit. This needs to be sent to the lab for

testing to determine the real water content (%).

5) For each sample of oil taken from the pipeline record the

actual ADC and Temperature values displayed at the top

of the “Measuring” tab.

6) Enter the values into a table and repeat the process for a

wide range of water contents in the oil.

7) After the results of the samples are sent back from the lab

fill in the rest of the table and determine the maximum and

minimum % values (e.g., max is sample 8 and min is 5).

8) Before setting the low and high points in the software

ensure that there is at least a 10 value difference between

the maximum and minimum values.

9) Connect a computer to the EASZ-2 using an original

USB-RS or USB-CL Com Cable.

10) Start the EASZ-2 software, click the “Calibration” tab and

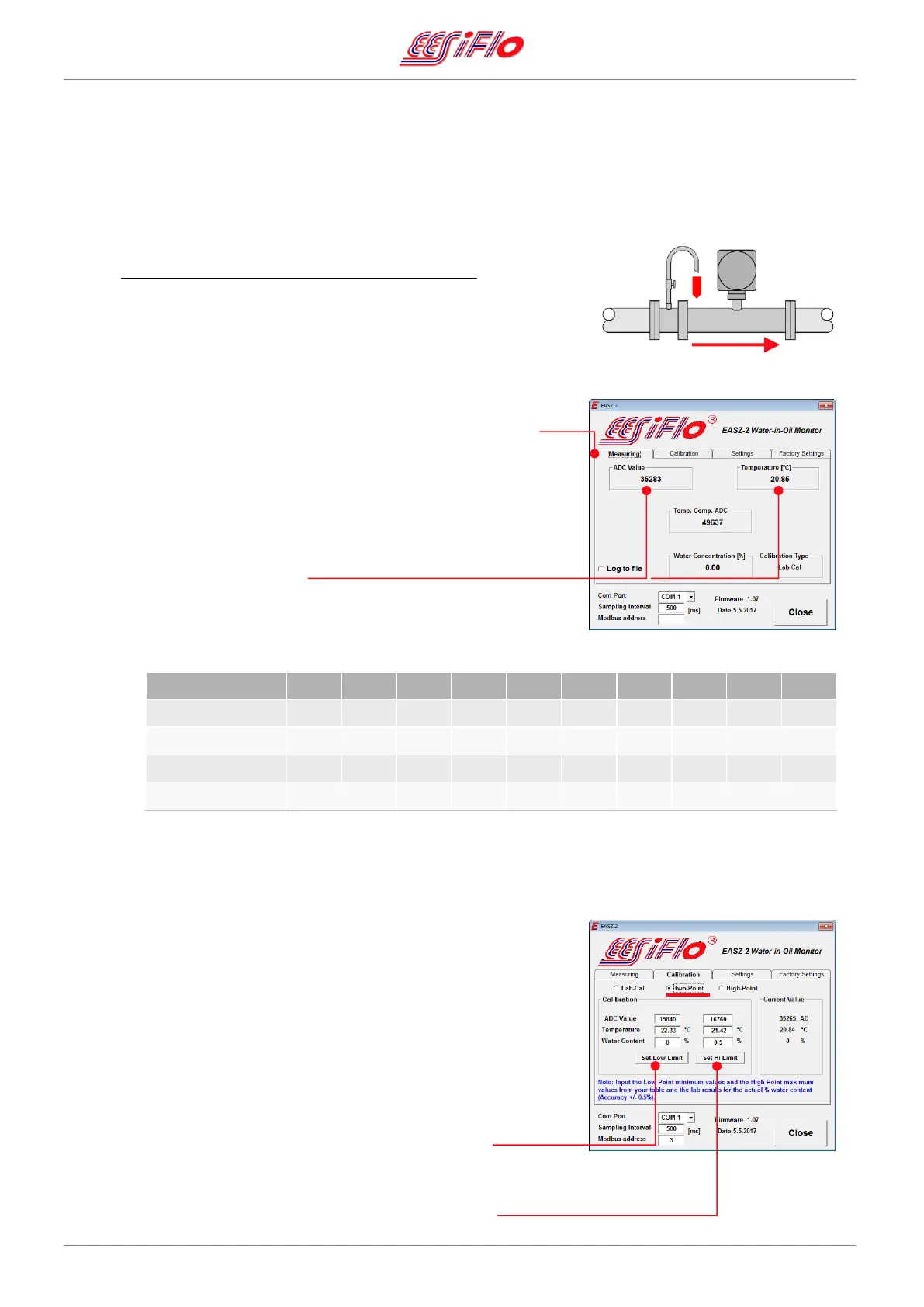

select the Two-Point Calibration option.

11) Add the min ADC and Temp values from the table and the

actual % Water Content value from the lab to the low-point

fields and then press the “Set Low-Point” button.

12) Add the max ADC and Temp values from the table and the

actual % Water Content value from the lab to the high-point

fields and then press the “Set High-Point” button.

Loading...

Loading...