13

ARCHIMEDE LCD SERIES - ENG

ELECTROIL

• At the end of the check the pump will work normally.

• Regulate the desired pressure value directly pressing buttons + or -, during pump working.

We suggest to use the ACCURATE CHECK specially for single-phase pumps, Jet, self-priming and periferical

types.

6.3 User’s check after Inverter setting

Check the pump stop to output closed: At the first installation open the output on the pump flow, press START,

wait a few seconds for the plant go to pressure set, then close the output flow (slowly) and make sure that the motor

stops (after a few seconds) showing on display "MINIMUM FLOW". In case the motor doesn’t stop you must select

MOTOR DATA - POWER STOP and set a higher value than the default (102%) set by the constructor. The absolute

stop power value is presented at regular times on display at the top-central position (see fig. 17).

Check pump dry-working: After installing, if is possible, close the suction/intake line in order to simulate a dry run

situation of the pump and check that, after approximately 40 seconds (or the delay time setting), the pump stop and

the display show the message “DRY WORKING”. If, after this time, the pump does not stop, you must enter into

MOTOR DATA and set a higher value of DRY WORKING STOP POWER (default 80%), otherwise enter on

ADVANCED FUNCTIONS – PRESSURE CONTROL setting a higher value of the parameter COSFI LIMIT (by

default set to 0.50). Save data after modifying.

6.4 Programming Functions

• Display:

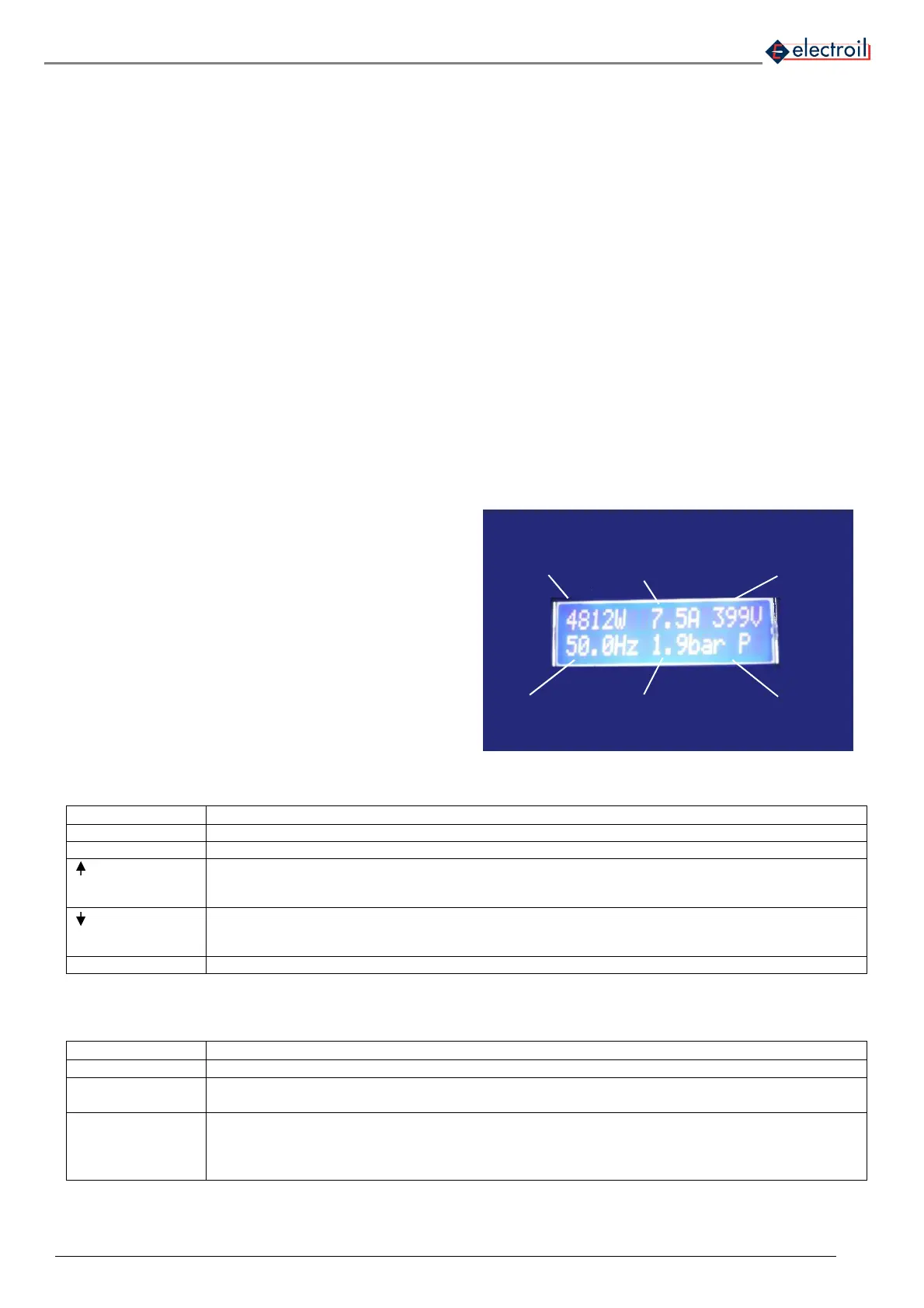

Figure 17: LCD Display data

• List of command on the control panel

FUN To enter on main functions menu

START/ENTER Pump start / To enter on the function and modify the values

+ It allows scrolling up the items on the menu or positive change in the value of variables; after the

variation press ENTER.

Encrease the reference pressure during functioning.

- It allows scrolling down the items on the menu or negative change in the value of variables; after the

variation press ENTER.

Decrease the reference pressure during functioning.

STOP/ESC Pump stop / To exit to the function and automatically saving

Table 3: List of commands on the control panel

• LED description

Power ON

• Green fixed: input voltage supply ON

Motor ON

• Green fixed: Motor running;

• Green flashing: before stopping for minimum flow

Alarm

• Red fixed: Alarm (see Alarm list – table 7). Require manually re-start (STOP+START)

• Red flashing high frequency: Alarm and motor stop with automatic re-start;

• Red flashing low frequency: Problem at the pressure sensor on group functioning – without

stopping pump

Table 4: Led description

INVERTER

POWER

ABSORBING

CURRENT ABSORBING

POWER FACTOR (PF)

MINIMUM FLOW STOP

/ INVERTER

TEMPERATURE

FREQUENCY

DELIVERY PRESSURE

PUMP (P) / MASTER-SLAVE

(C0, C1, ..)

Loading...

Loading...