15

ARCHIMEDE LCD SERIES - ENG

ELECTROIL

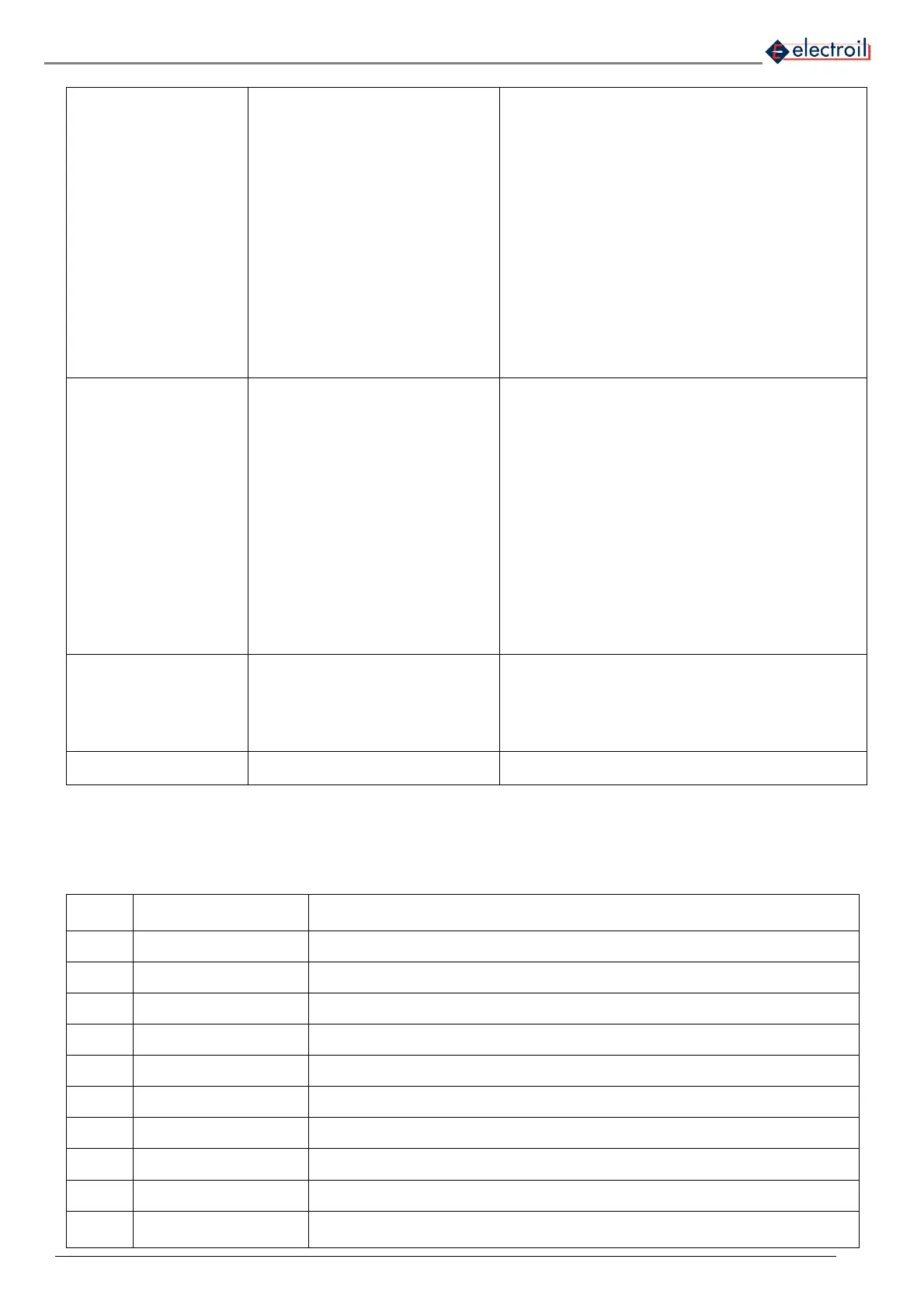

Pressure Control

1. Pressure Hysteresis [BAR]

2. Max Limit Pressure [%]

3. Dry working stop delay [s]

4. Dry working re-start delay time

[min]

5. Minimum flow stop delay [s]

6. Re-start delay after minimum flow

stop [s]

7. Cos φ limit

8. Alternation time

1. Pressure control hysteresis- Default: 0.20 BAR;

2. Max value of pressure % referred to Set-point

pressure value – Default: 130% (increase the value

up to 200% in case of alarm 14 “Max Pressure”);

3. Dry working stop delay time for pump filling– Default:

40 seconds;

4. Dry working re-start delay time after firsts 4th try;

after the 5th try the Inverter stop with manual re-start

(STOP + START)– Default: 15 minutes;

5. Delay time before minimum flow stop – Default: 15

second;

6. Re-start delay time after minimum flow stop -Default:

1 second;

7. When cos φ go down this value the pump stop for

dry working (may be absence of input water or air) –

Default: 0.5;

8. Alternation time on the change from one to other

pump to define the first to start

Group Functioning

1. Control type

• Pump Speed

• Pump Pressure

• MasterSlave

2. Reference speed [RPM]

3. Pumps number (2..8)

4. Code (0..7)

5. Radio Frequency (780..820 MHz)

6. Stand-by preheating temperature

1. Set Control Type (Default: Pump Pressure):

• Pump speed: directly regulation of the speed in

absence of pressure sensor; security stop for null

flow and dry working conditions, only with manually

re-start.

• Pump pressure: feedback control of pressure - need

the pressure sensor;

• MasterSlave – group functioning with others Inverters

2. Value of the reference speed on the Speed control;

3. Pumps Number: Number of pumps in group

functioning (2..8).

4. Code: 0 for Master; >=1 for Slave

5. Radio Frequency: communication R/T frequency

(must be the same for the inverters on the group)

6. Minimum preheating temperature with the engine

stopped – Default: 25°C (the function can be

deactivated by setting the relevant parameter to 0)

P.I.D. factors

1. K

proportional

2. K

integral

3. Pressure ramp

1. K

proportional

: 0-100. Pressure error multiplayer –

Default: 25

2. K

integral

: 0-100. Integral of pressure error

multiplier - Default:25

3. Pressure ramp [bar/s]: 0.1-10.00 – Default: 0.5

BAR/s

Alarm history

Alarm N°

Type

Visualization of last 100 alarm events (see table 7) in

chronologic order.

Table 6: advanced functions sub-menu

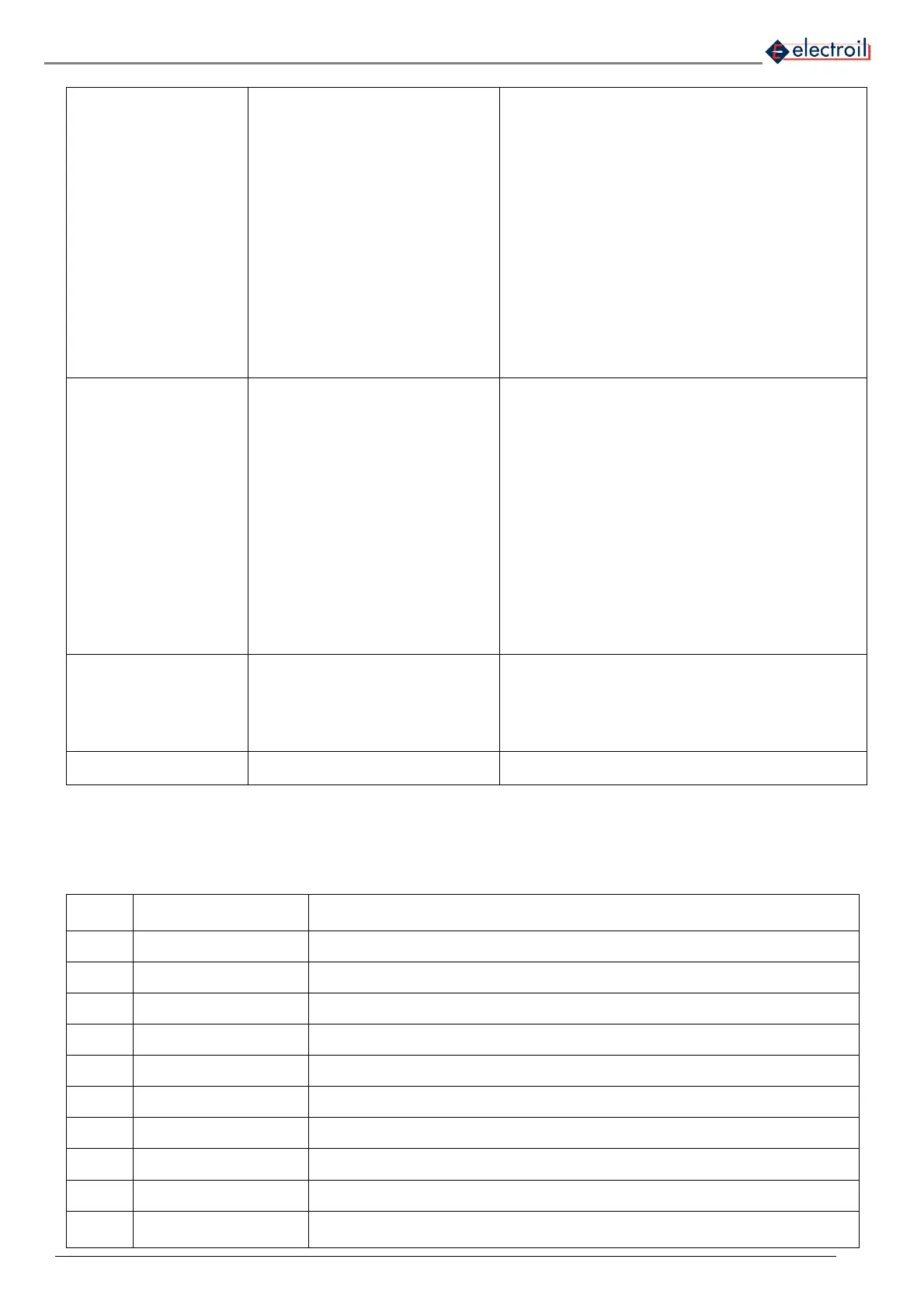

6.5 Alarms

N°

Alarm Type Description

1

Current Peak

Immediately stop probably caused by short-circuit

Automatic re-start; final stop after 10 consecutive events

2

Over-Voltage

Normally caused by over voltage pick supply. Automatic re-start; final stop after 10

consecutive events

3

Inverter Temperature

Over temperature IGBT protection (90°C)

Automatic re-start; final stop after 10 consecutive events

4

Thermal protection

Motor thermal protection related to nominal current set, for motor insulations saving at high

temperatures. Automatic re-start; final stop after 10 consecutive events

5

Dry operating

Null input flow or air presence;

Automatic re-start; final stop after 5 consecutive events

6

Pressure sensor problem

Pressure sensor output problem

Automatic re-start; final stop after 10 consecutive events

7 Under-Voltage

Input voltage under the minimum working limit.

Automatic re-start; final stop after 10 consecutive events

8 Enable OFF

Open contact between EN e C (figure 14-15-16): stop the motor; the motor restart when

the contact will close again

9 Over-Current IGBT

Over current on the IGBT, overtaking a current limit value setting

Automatic re-start; final stop after 10 consecutive events

10 INPUT-OUTPUT

inverted

Connection mistake: Voltage supply connected on the output and Motor cable connected

on the entrance: reverse in order to enable the motor

Loading...

Loading...