104

Page

Installation

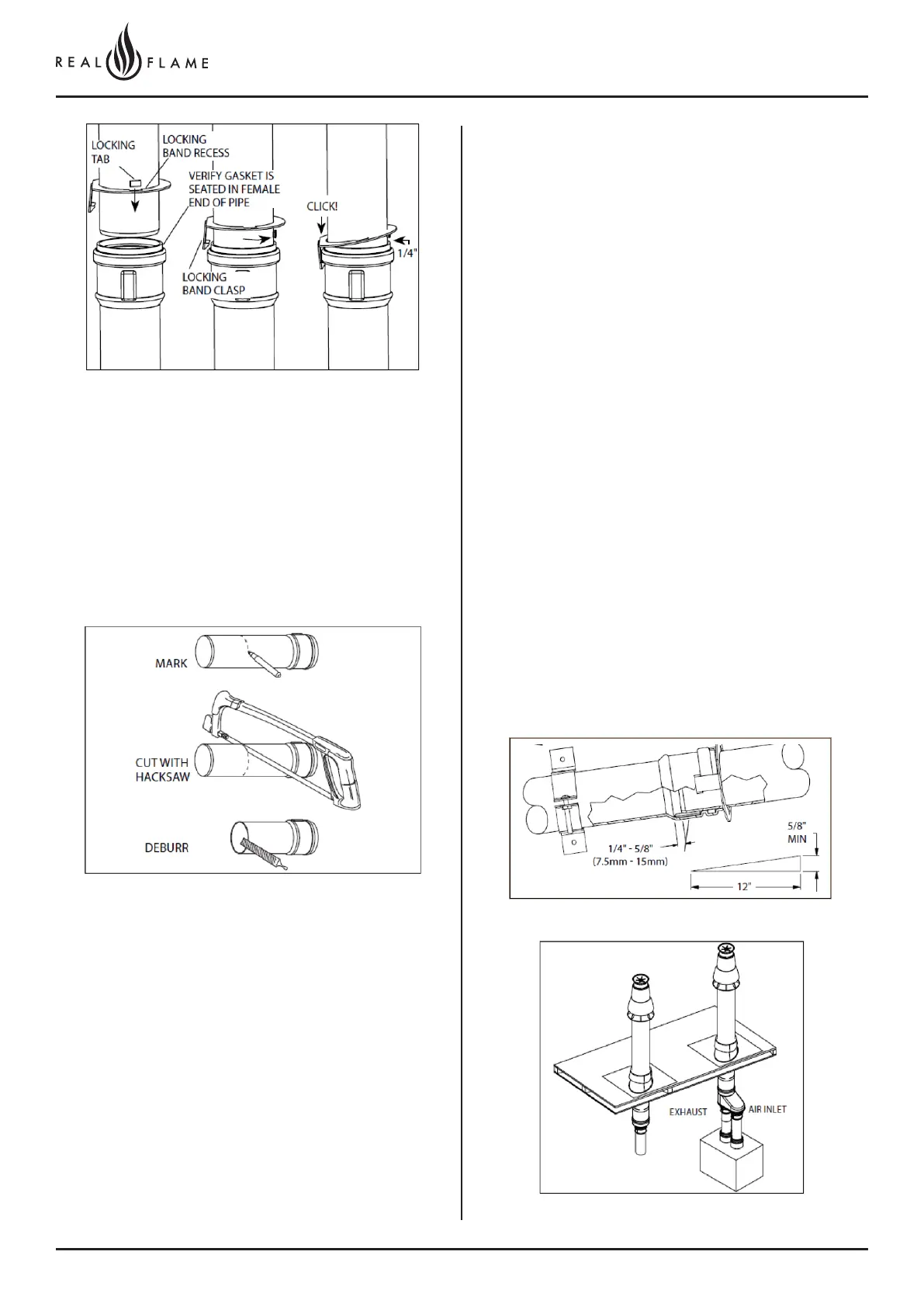

1. Pipe lengths may be cut to length. Use an alternative

clamp (PPS-PAC/PPS-LBC) for the connection if a

locking tab is removed.

• Cut square (not an angle) to the end of the pipe.

• Remove burrs before assembly.

2. Check with appliance manufacturer for any restrictions

or limits on vent length, number of elbows, etc.

3. The slope of the vent pipe must be at least 3° (50mm

per meter) back to the appliance.

4. Every horizontal section must be supported.

5. The venting system shall be securely supported

using suitable hangers. Duravent hardware is

recommended; field supplied support hardware

suitable to the AHJ is acceptable, hardware must not

deform on damage the vent. Make sure the load on

the vent system is not supported by the appliance. On

Duravent and other certain clamp styles, 1/4˝ or

greater All-thread may be used as an extension.

6. Vertical installations must be supported every 3 meters

or less.

7. Elbows and tees are sufficiently supported when a

bracket is fixed at the female end of the connected

straight section.

Vertical Concentric

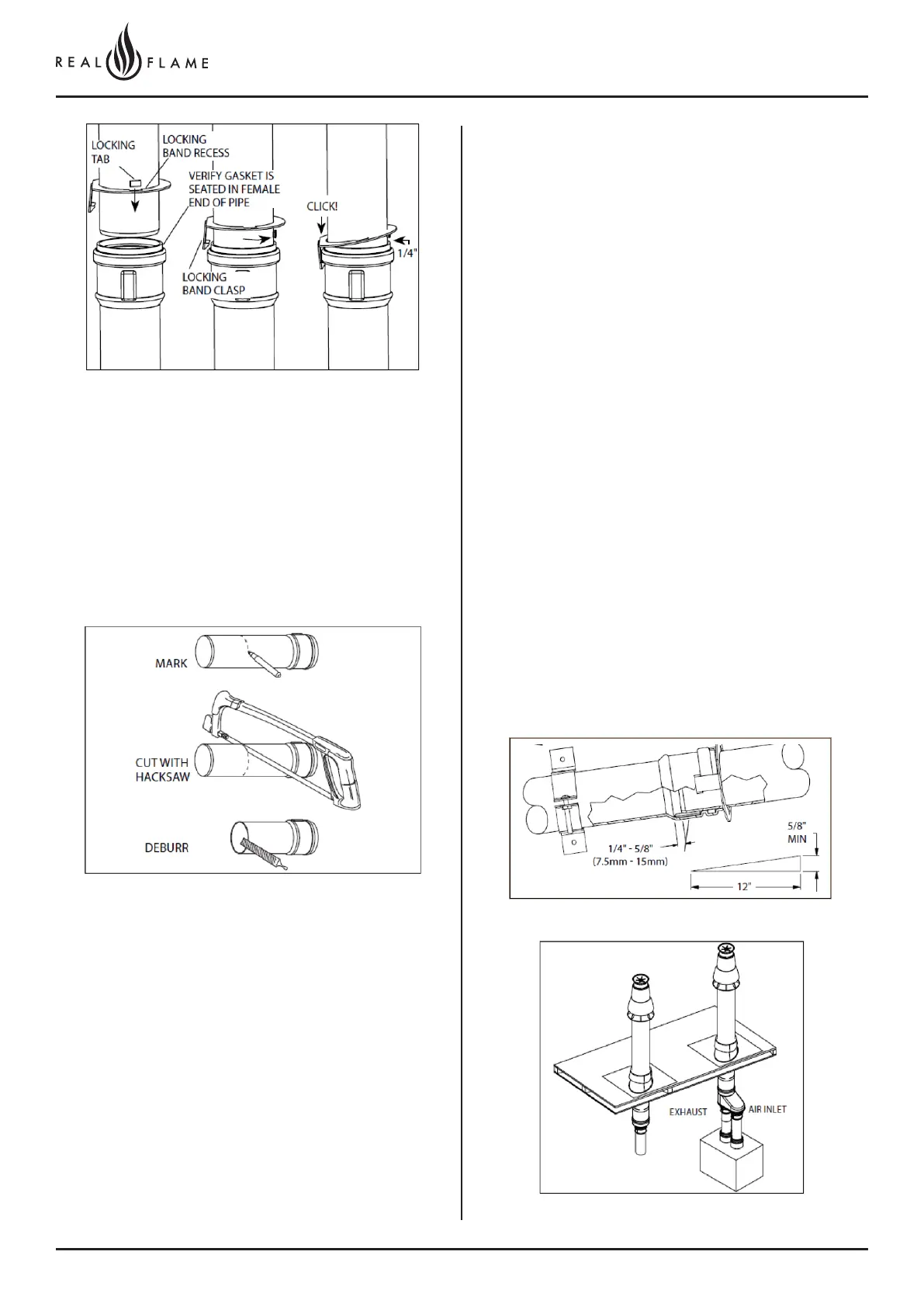

1. Locate penetration.

2. Cut hole in roof.

3. Cut hole in ceiling above appliance.

Cut hole(s) big enough for pipe in all ceilings above

appliance if installing in a multi storey installation.

4. Firestop each ceiling penetration.

5. Attach flashing to roof.

Slide storm collar onto flashing if using the adjustable

roof flashing.

6. Slide vertical termination into flashing from above

until seated on flashing.

7. Plumb termination and mount support bracket to

structure.

Loading...

Loading...