mages or holes that can prevent proper function. The plastic hoses should not

be used in temperatures over 90ºC (194 ºF). If your application temperature

exceeds this temperature/pressure, we recommend to use copper or stainless

steel tubing, depending on the compatibility to the measured gas or liquid (see

section 2.4)

Installation of the Pipe Section

Note!!! Before starting to install the Pipe Section, please make sure

that the piping is not under pressure from flow of liquid/gas!

The pipe section can be installed in any desired direction, vertically or hori-

zontally or angular and the direction arrow on the pipe section denote the di-

rection of the flow. It is very important that the pipe section is mounted with

the correct direction, as the function of the Flow Monitor otherwise will be

prevented. The piping shall be rigid and free from vibrations and hoses con-

nected directly into the Monitors should be avoided as much as possible. If

you have weak piping we advise you to use the M6 mounting holes (only on

GL - series) on the backside of the pipe section, to fasten the pipe section to a

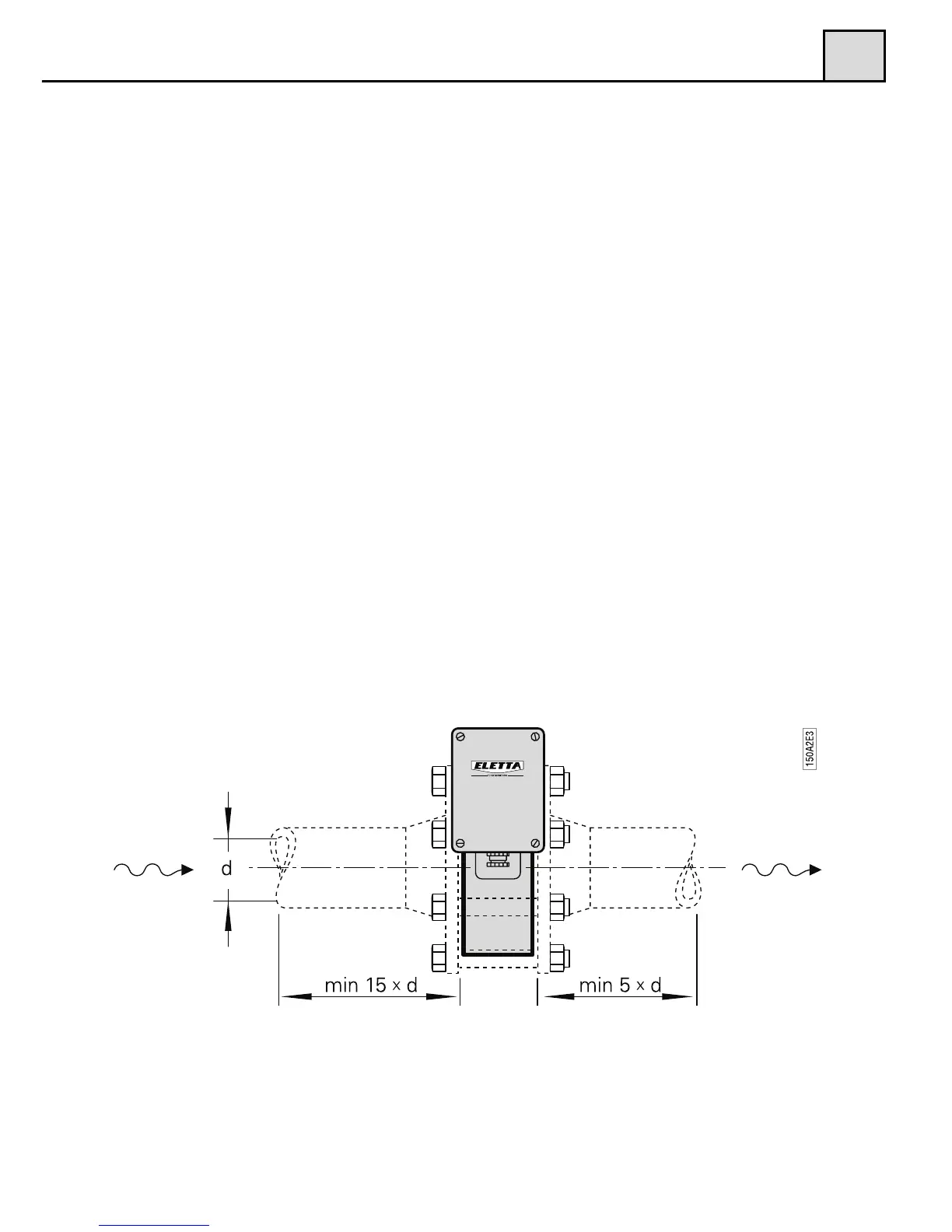

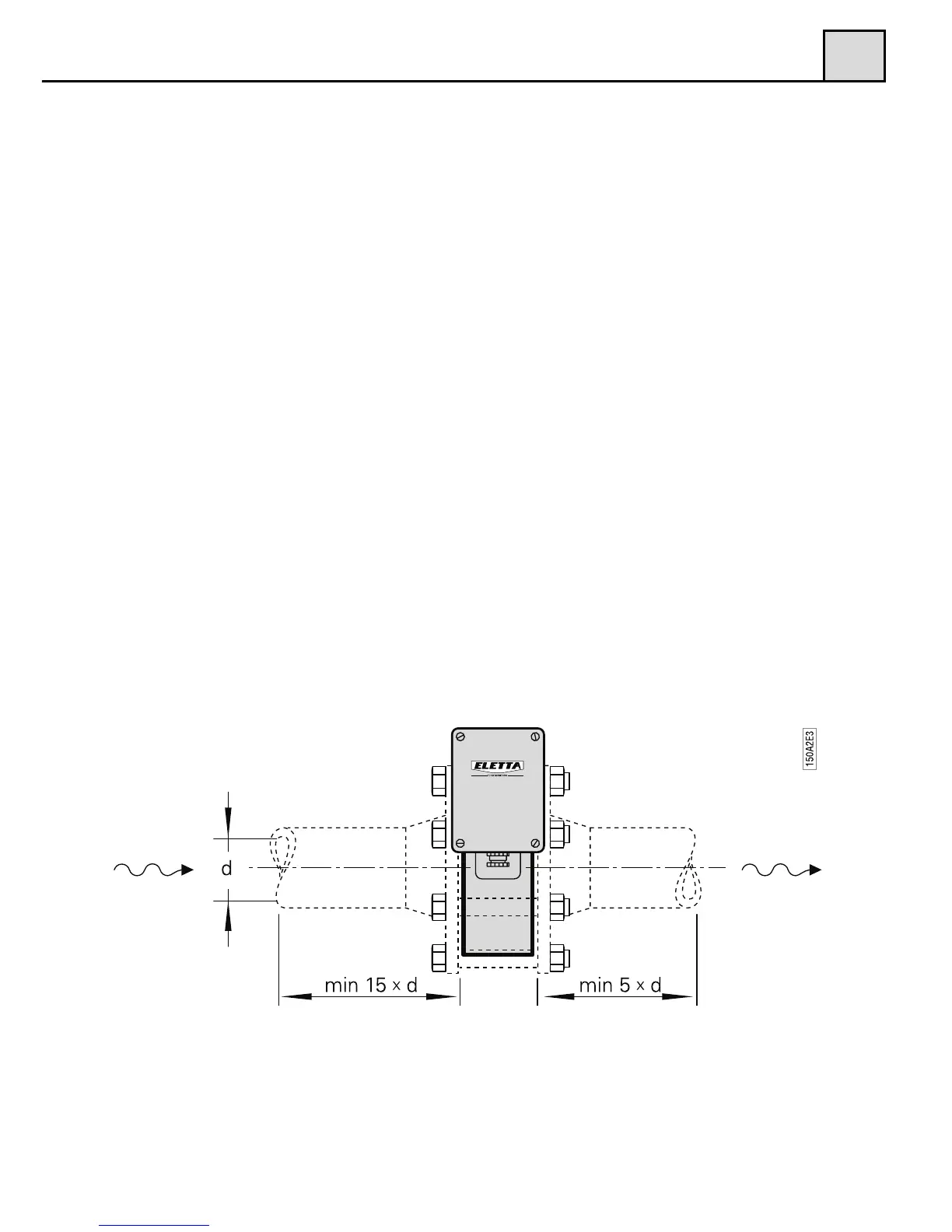

wall or a rigid bracket. The straight runs before and after the Monitor should

not be too short, in order to avoid disturbances, which can cause the Monitor

to show incorrect values. We recommend giving at least 10 - 15 diameters up-

stream and 5 diameters downstream. (Please see Fig. 1)

The reasons for this procedure is to achieve a stable flow profile inside the

pipe and by doing so, get a true reading. Please be aware of the fact that it is

practically impossible to predict when the flow is stable after disturbances in

the piping, so this must serve as a guideline only. The straight runs must be

Loading...

Loading...