Introduction

Parameter

x.00

Parameter

description format

Keypad and

display

Serial

communications

CT Modbus

RTU

PLC Ladder

programming

CTSoft Menu 0

Advanced parameter

descriptions

Menu 11

Commander SK Advanced User Guide 145

Issue Number: 9 www.controltechniques.com

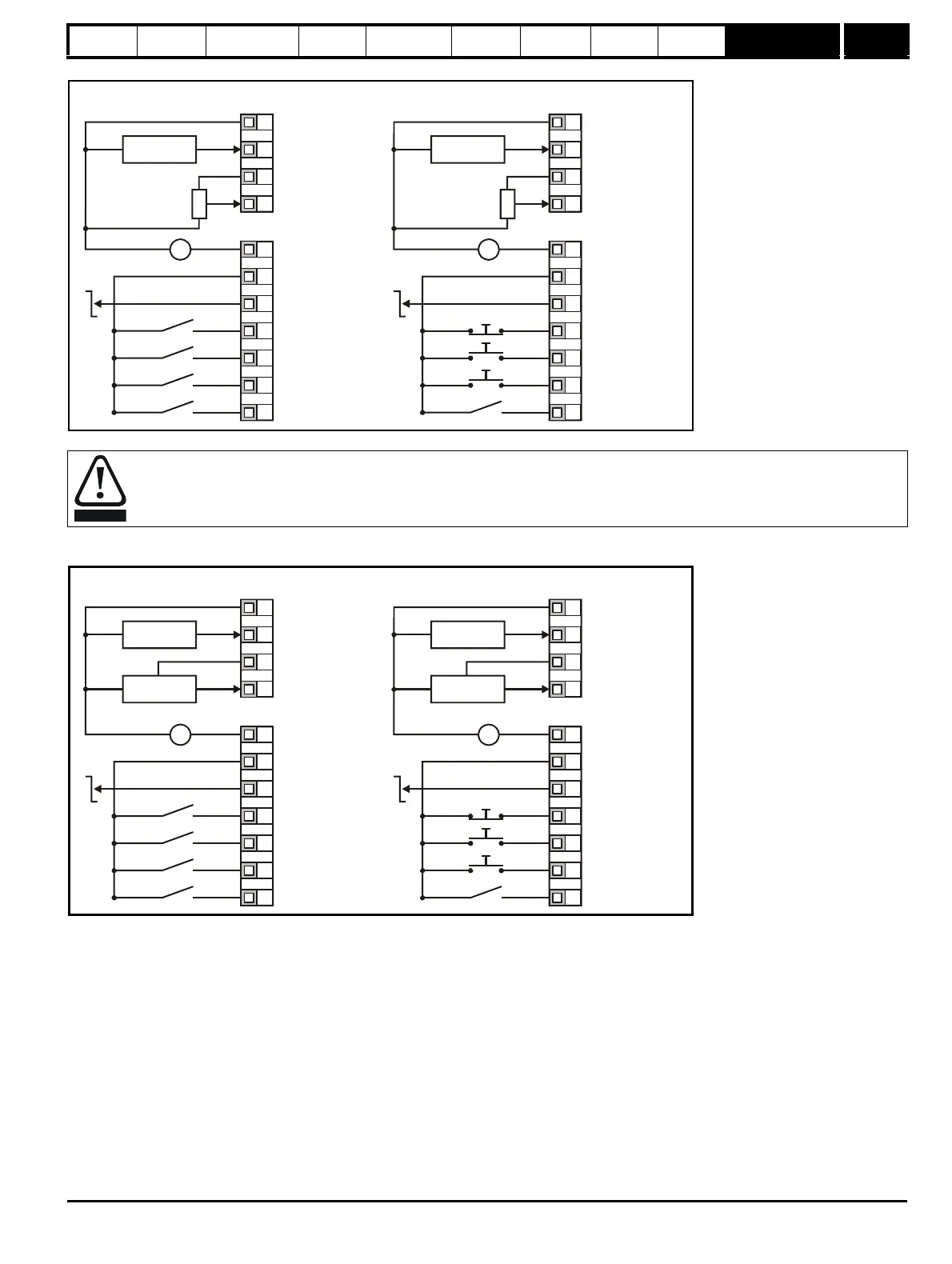

Figure 10-32 Pr 11.27 = tor

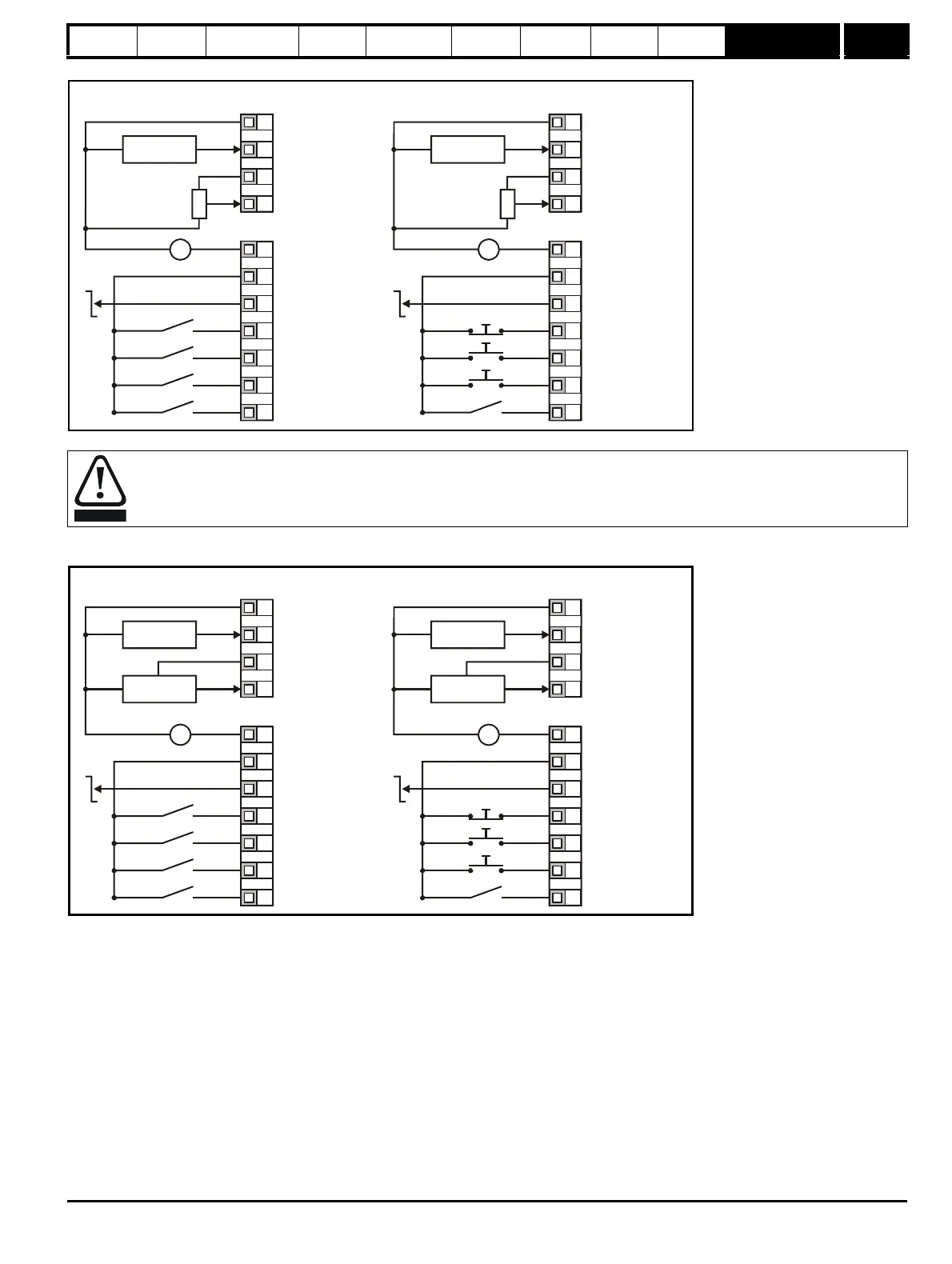

Figure 10-33 Pr 11.27 = Pid

When Pr 11.27 is set to Pid, the following parameters are made available for adjustment:

•Pr 14.10: PID proportional gain

•Pr 14.11: PID integral gain

•Pr 14.06: PID feedback invert

•Pr 14.13: PID high limit (%)

•Pr 14.14: PID low limit (%)

•Pr 14.01: PID output (%)

When torque mode is selected and the drive is connected to an unloaded motor, the motor speed may increase rapidly to the maximum

speed (Pr 02 +20%)

0V

Remote current speed

reference input (A1)

+10V reference output

Torque reference

input (A2)

+24V output

Drive Enable/Reset

Run Forward

Run Reverse

Torque mode

select

Remote speed

reference input

V

_

+

10k

(2kmin)

+24V

0V

Eur USA

Analog output

(motor speed)

Digital output

(zero speed)

0V

Remote current speed

reference input (A1)

Torque reference

input (A2)

select

Remote speed

reference input

V

_

+

10k

(2kmin)

+24V

0V

(zero speed)

T1

T2

T3

T4

B1

B2

B3

B4

B5

B6

B7

T1

T2

T3

T4

B1

B2

B3

B4

B5

B6

B7

0V

+10V reference output

+24V output

Drive Enable/Reset

Run Forward

Run Reverse

4-20mA PID

feedback input

V

_

+

+24V

0V

Eur USA

Analog output

(motor speed)

Digital output

(zero speed)

PID feedback input

PID reference input

PID enable

0-10V PID

reference input

0V

/Stop

Run

Jog

4-20mA PID

feedback input

V

_

+

+24V

0V

PID enable

0-10V PID

reference input

PID feedback input

T1

T2

T3

T4

B1

B2

B3

B4

B5

B6

B7

T1

T2

T3

T4

B1

B2

B3

B4

B5

B6

B7

Loading...

Loading...