10 Chapter 3 Application Of Fan Speed Controller

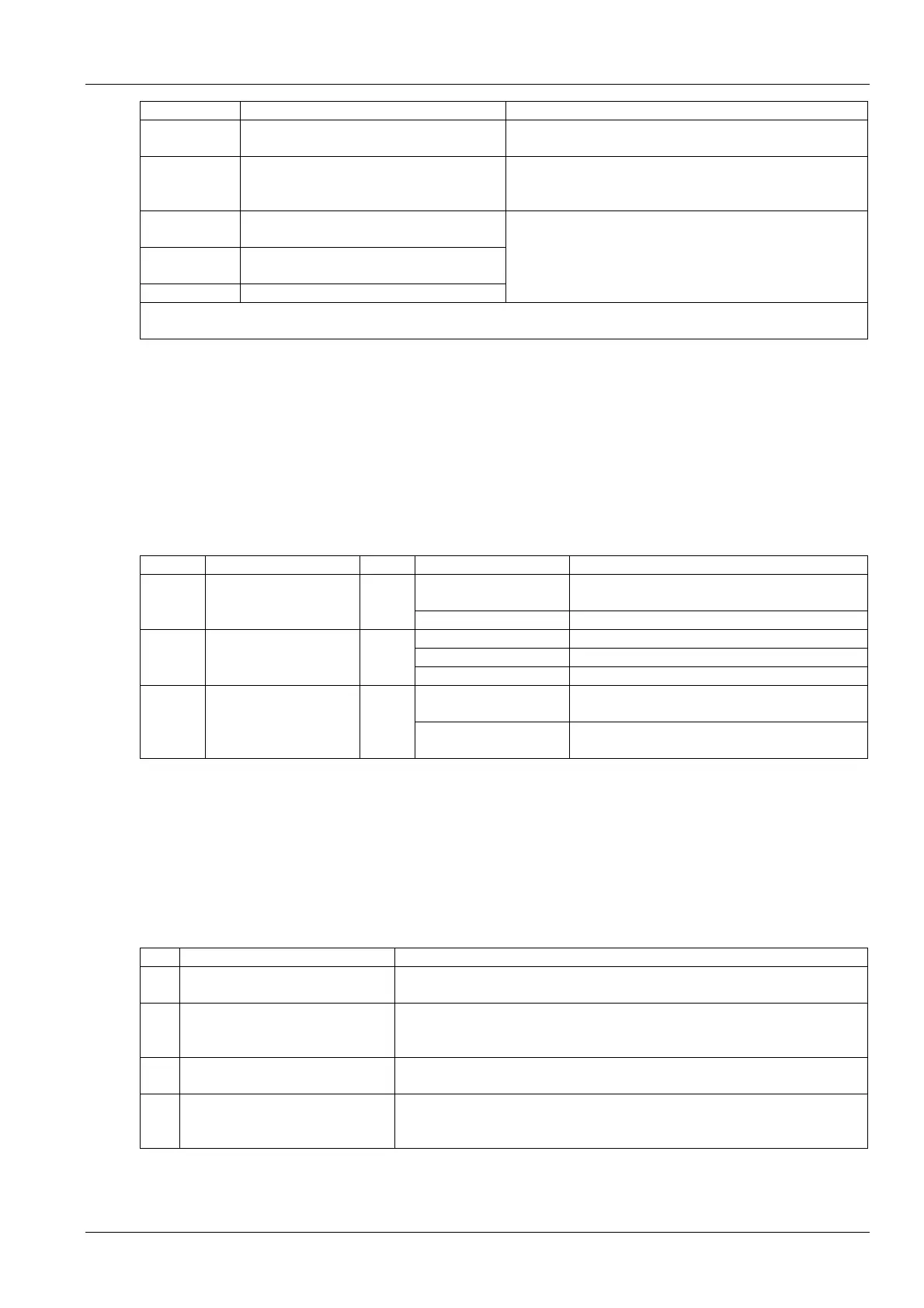

Silk print Definition Definition of pins

J5 (Out Temp)

Input terminal of ambient temperature sensor

(spare)

Pin 1: input terminal of temperature signal

Pin 2: signal ground

J11 (RS232)

Serial communication interface (used for

maintenance)

Pin 1: communication ground

Pin 2: reception terminal of communication

Pin 3: transmission terminal of communication

J7 (Fan1Sta)

Detecting terminal of fan 1 over temperature

state

J10 (Fan2Sta)

Detecting terminal of fan 2 over temperature

state

J6 (CompSta) Detecting terminal of compressor state

Pin 1: output terminal of 19Vac signal

Pin 2: return terminal of 19Vac signal

Note:

J8 (SCRTemp) in Figure 3-1 is the interface of fan speed controller board, and not to be used by users

3.2 HMI

The fan speed controller operation and setup is provided through indicators, RS232 serial communication port, keys

and LCD.

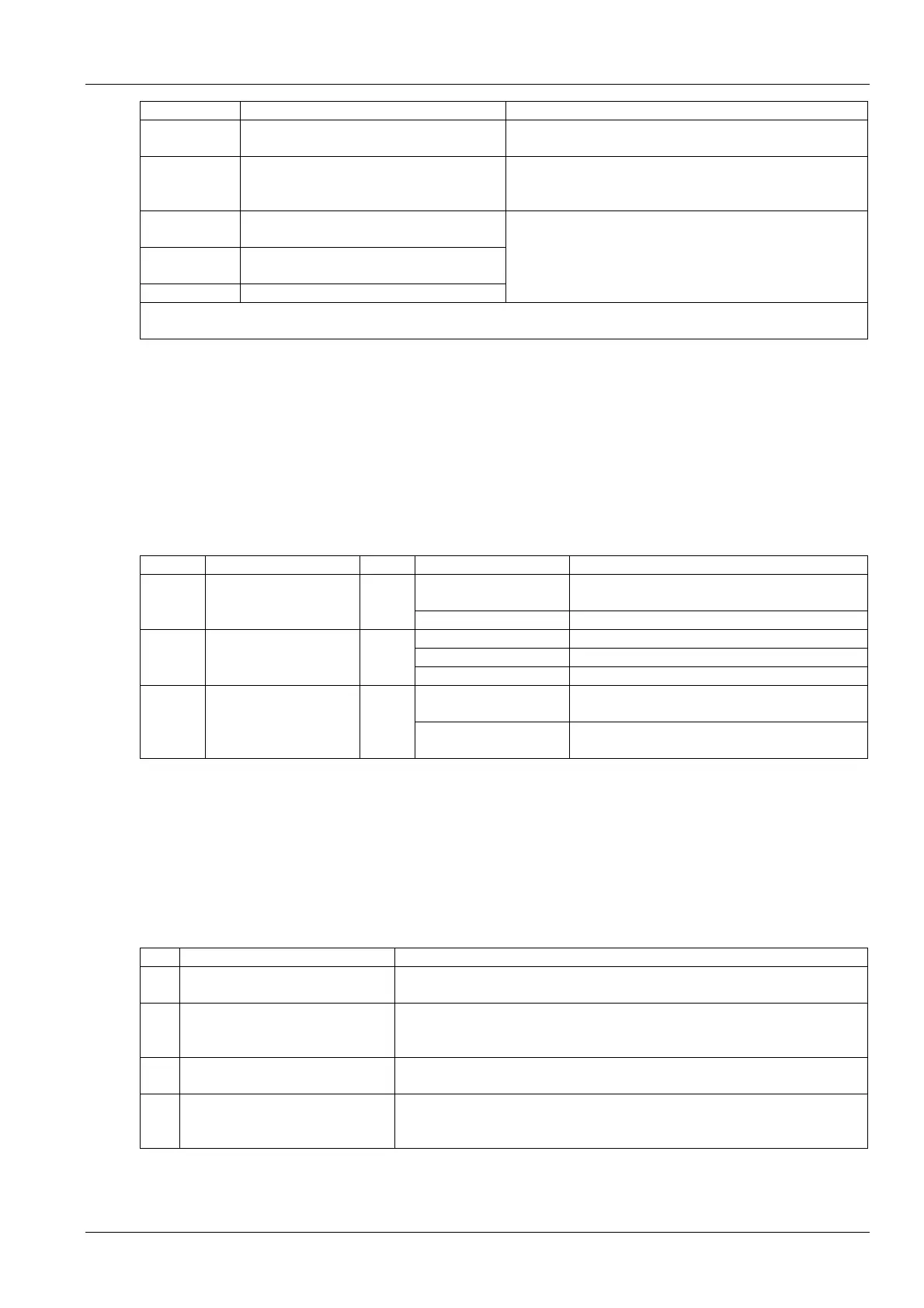

Indicators

There are three indicators (see Figure 3-1) on the fan speed controller board. See Table 3-2 for the functions of

indicators.

Table 3-2 Functions of indicators

Silk print Definition Color State Function

On

The CPU circuit of fan speed controller board is

supplied with 5V power

D16 Power indicator Green

Off The fan speed controller board is faulty

On or off The fan speed controller board is faulty

Blinking at 1Hz (slowly) The system is running normally without alarm

D22 Run indicator Green

Blinking at 5Hz (quickly) There is an alarm or the compressor is shut down

On

The control switch which supplies the AC contactor

with the driving power is open

D15

Power switch controlling

indicator of AC contactor

Red

Off

The control switch which supplies the AC contactor

with the driving power is closed

RS232 serial communication port

The RS232 serial communication port is a port to connect the computer using factory-defined protocol. It is used for

factory commissioning and maintenance.

Keys and LCD

The keys and LCD, which can realize the functions in Table 3-3, provide the HMIs for maintenance personnel. Refer to

3.3 Operation Description Of HMI for operation of keys and LCD HMI.

Table 3-3 Function descriptions of keys and LCD

NO. Function Description

1

Query the acquisition data in real

time

The acquisition data include condensing pressure, ambient temperature, silicon

controlled rectifier (SCR) temperature and output percentage

2

Query the current alarm data in real

time

The current alarm data include phase loss alarm, SCR over temperature, fan 1 over

temperature, fan 2 over temperature, pressure sensor failure, EEPROM read fault

alarm, SCR temperature sensor failure and abnormal frequency

3

Query the historical alarm data in

real time

The latest saved 100 historical alarms can be queried

4

Modify the configured parameters in

real time

The configured parameters include running pressure, pressure controlling range,

minimum voltage, maximum voltage, fan number and pressure sensor type; or

resume the default values

Liebert.PEX Condenser User Manual

Loading...

Loading...