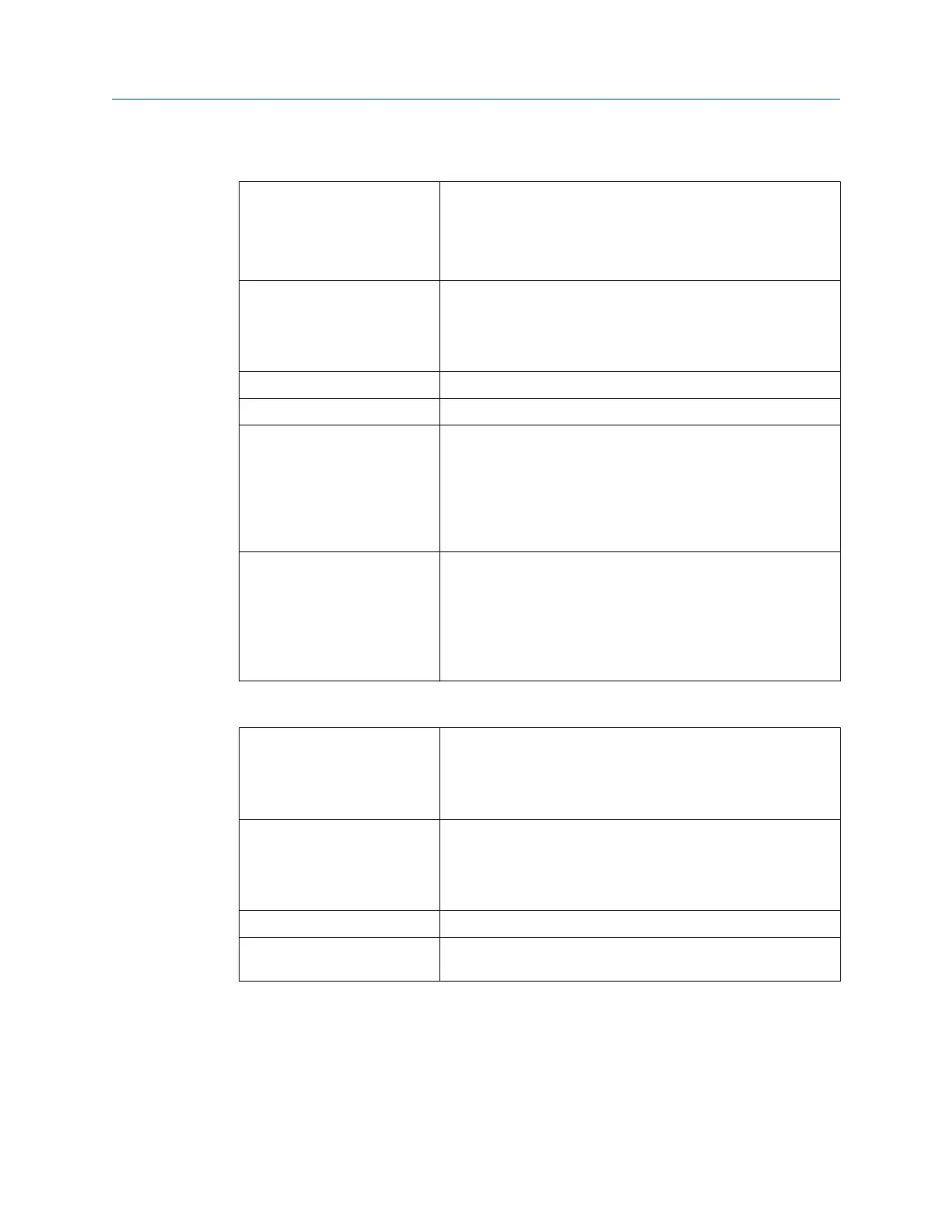

T-piece applications

Flow rate 0.5 to 3 m/s at main pipe wall

By increasing the insertion depth of the tines into the T-piece, the

flow velocity can be increased to 5 m/s for clean fluids. For slurry

applications, the maximum flow velocity should be no greater

than 4 m/s.

Viscosity • For the 2 in (51 mm) (DN50) T-piece, viscosity limit is 100 cP

(200 cP in some cases).

• For the 3 in (76 mm) ( (DN80) T-piece, the viscosity limit is

1000 cP.

Temperature -58 °F (-50.0 °C) to 392 °F (200.0 °C)

Main flow pipe size Minimum diameter, 2 in (51 mm)

Advantages • Simple installation in large bore pipes

• Ideal for clean fluids and non-waxing oils

• 3 in (76 mm) T-Piece installation ideal for high percentage

slurry applications

• Suitable for line density measurement and simple referrals

Recommendations Do not use with:

• Low or unstable flow rates

• Where step changes in viscosity can occur

• For small bore pipes

• Where temperature effects are significant

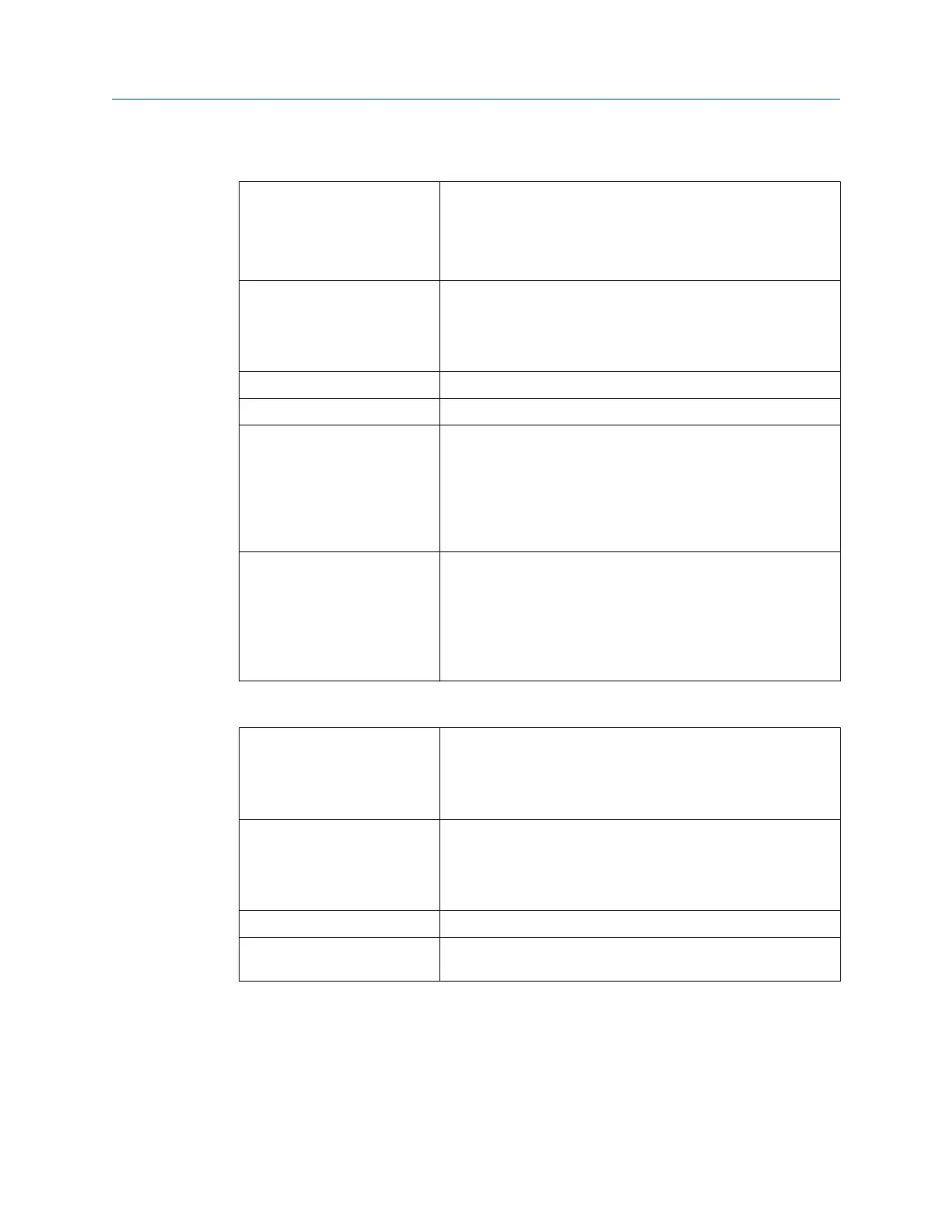

Flow-through chamber applications

Flow rate

• 5–40 l/min for 2 in (51 mm) Schedule 40 calibration bore

section (1.5 - 10.5 gal/min)

• 5–300 l/min for 3 in (76 mm) Schedule 80 calibration bore

section (1.5 - 80 gal/min)

Viscosity • For the 2 in (51 mm) (DN50) Flow Chamber, viscosity limit is

100 cP (200 cP in some cases).

• For the 3 in (76 mm) (DN80) Flow Chamber, the viscosity

limit is 1000 cP.

Temperature -58 °F (-50.0 °C) to 392 °F (200.0 °C)

Main flow pipe size Suitable for all sizes, if mounted in a bypass (slipstream)

configuration

Installation Manual Planning

MMI-20020989 May 2019

Installation Manual 13

Loading...

Loading...