Important

Do not alter the length of the inlet and outlet pipes. Pipe alterations can adversely affect

the fitting temperature response and stability.

Prerequisites

Verify the following conditions:

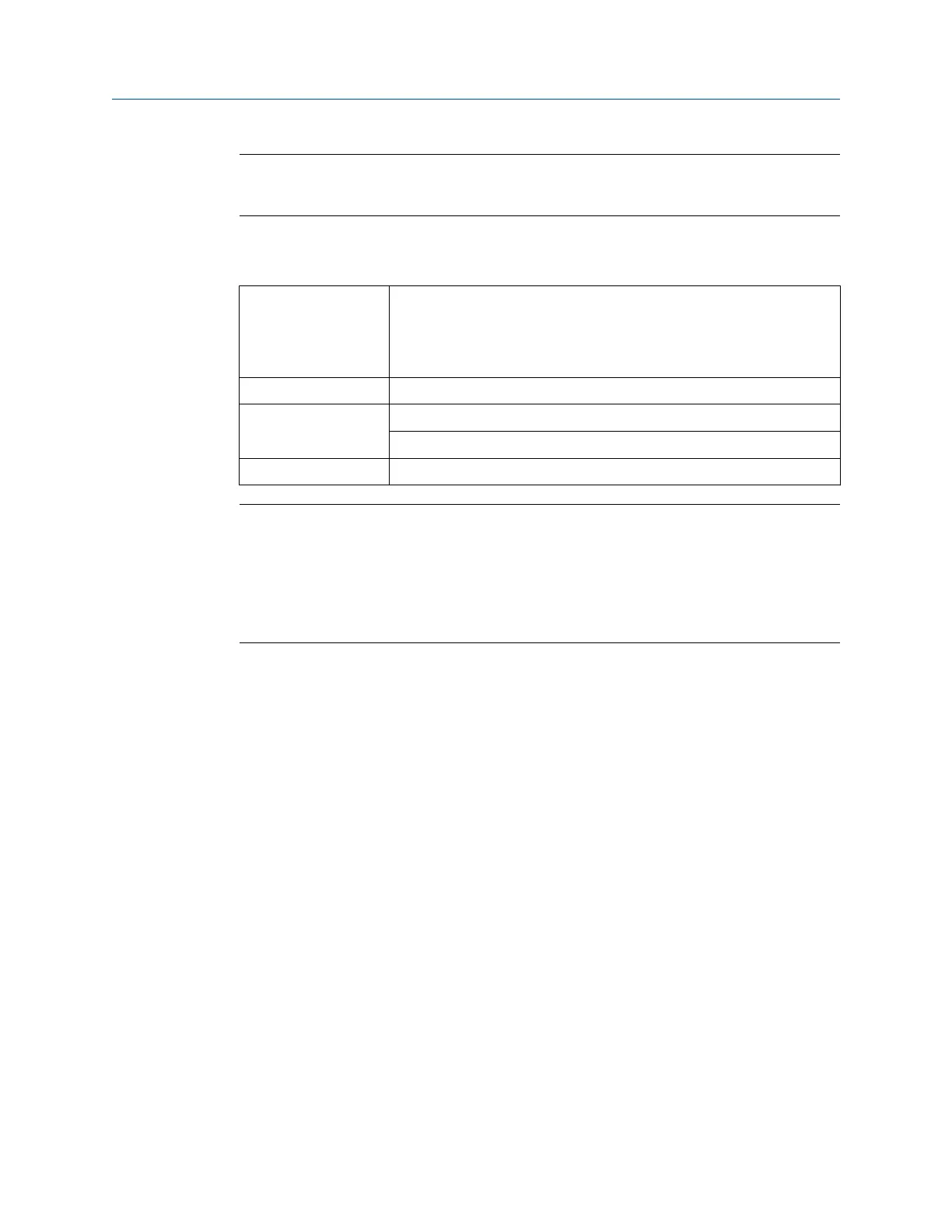

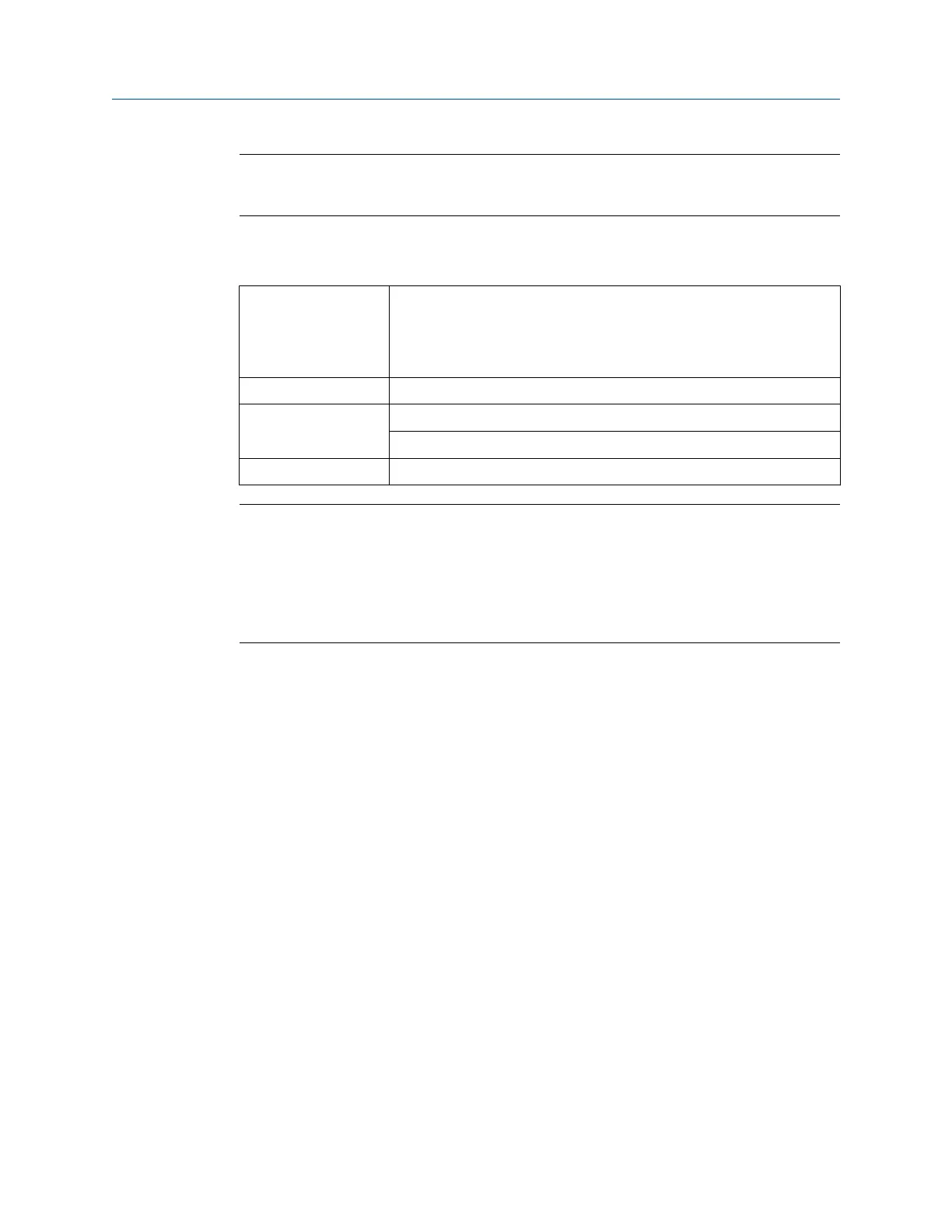

Flow • 5–40 l/min for 2 in (51 mm) Schedule 40 calibration bore section (1.5

- 10.5 gal/min)

• 5–300 l/min for 3 in (76 mm) Schedule 80 calibration bore section

(1.5 - 80 gal/min)

Viscosity Up to 1000 cP

Temperature -58 °F (-50.0 °C) to 392 °F (200 °C)

-40 °F (-40.0 °C) to 392 °F (200 °C) in hazardous areas

Pressure 1,015.26 psi (70 bar) @ 399 °F (203.9 °C), subject to process connections

Important

• To ensure that the fluid within the pocket is refreshed in a timely manner, verify that

flow velocity at the pipe wall and fluid viscosity are within the limits described in this

table.

• The thermal mass of the flanges may affect the response time of the meter to

temperature changes.

Procedure

See Figure 3-11 for an example installation of a meter in a flow-through chamber.

Installation Manual Mounting

MMI-20020989 May 2019

Installation Manual 27

Loading...

Loading...