48 Micro Motion

®

Model D and DT Sensors Instruction Manual

Troubleshooting continued

c. Use a DMM to measure resistance across wire pairs at the

transmitter end of the cable. See table on page 48.

• If the measured value is within the range listed in the table,

reconnect wiring and restore power to the transmitter.

• If the measured resistance is outside the range listed in the table,

repeat the measurements at the sensor junction box.

- If the sensor is a not a D600, refer to the “Nominal resistance

ranges” table below.

- If the sensor is a D600, refer to the table and illustration on

page 49.

- If resistance values measured at the sensor are also outside the

range listed in the table, the sensor might be faulty.

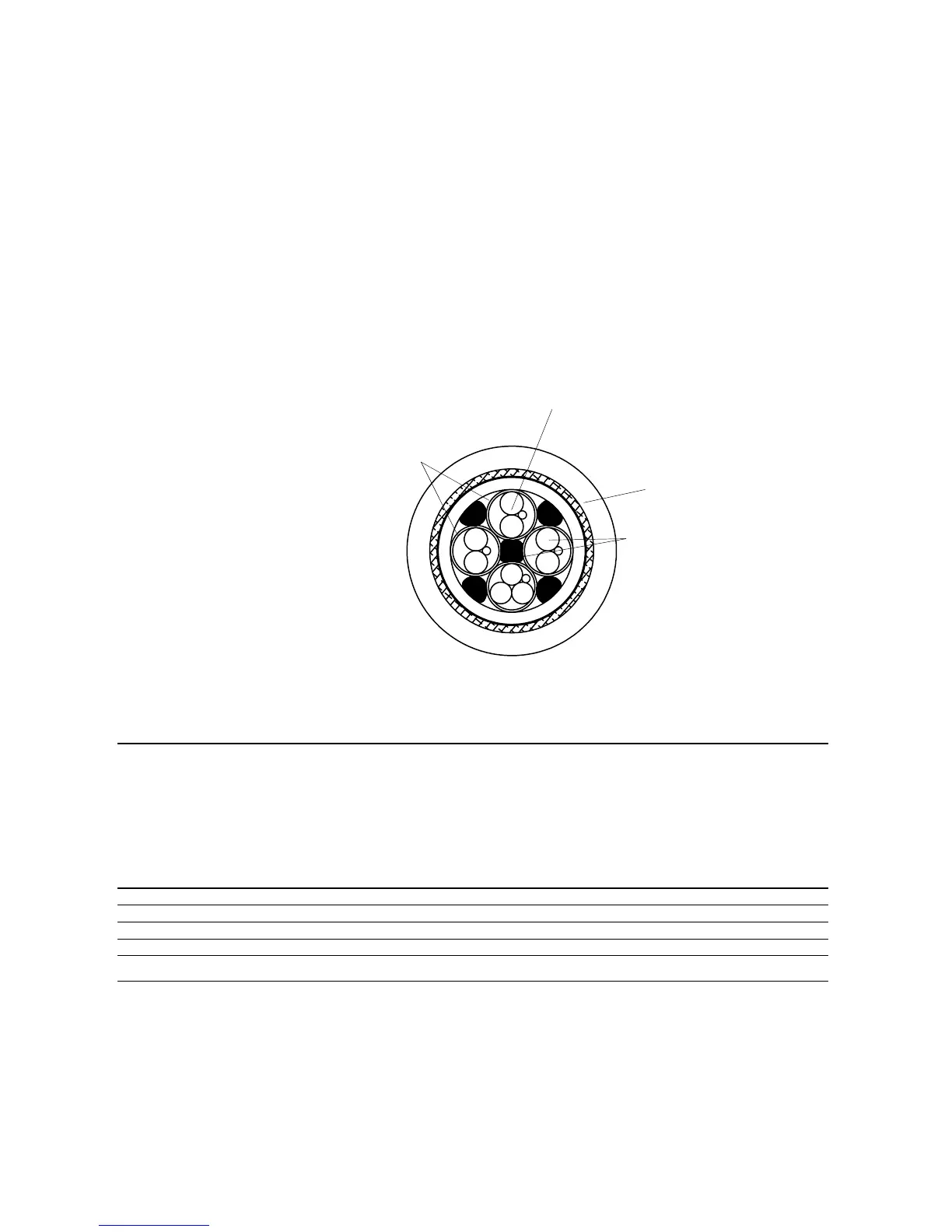

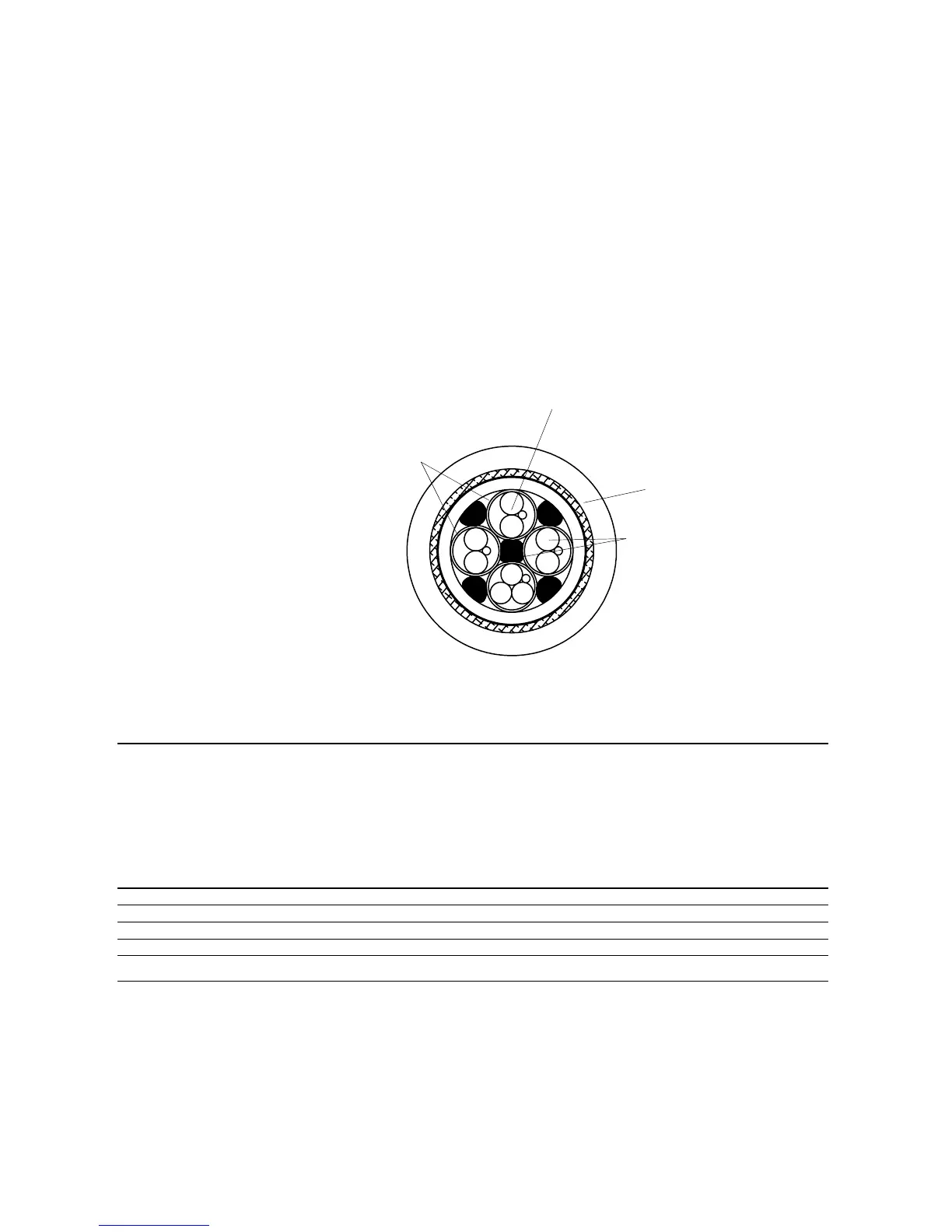

Cross-section of cable with drain wires

Table 6. Nominal resistance ranges for flowmeter circuits (for all D and DT sensors except the D600)

Notes

• Disconnect wires from terminals before checking resistance values.

• Temperature-sensor value increases 0.38675 ohms per °C increase in temperature.

• Nominal resistance values will vary 40% per 100°C. However, confirming an open coil or shorted coil is more important than

any slight deviation from the resistance values presented below.

• Resistance across blue and gray wires (right pickoff circuit) should be within 10% of resistance across green and white wires

(left pickoff circuit).

• Actual resistance values depend on the sensor model and date of manufacture.

• Reading across wire pairs should be steady.

Circuit Wire colors Sensor terminals* Nominal resistance range

Drive coil Brown to red 1 to 2 8 to 2650 Ω

Left pickoff Green to white 5 to 9 16 to 300 Ω

Right pickoff Blue to gray 6 to 8 16 to 300 Ω

Temperature sensor Orange to violet 3 to 7 100 Ω at 0°C + 0.38675 Ω / °C

Lead length compensator Yellow to violet 4 to 7 100 Ω at 0°C + 0.38675 Ω / °C

* For transmitter terminal designations, refer to the table below. For D600 sensors, see the illustration and table on page 49.

Loading...

Loading...