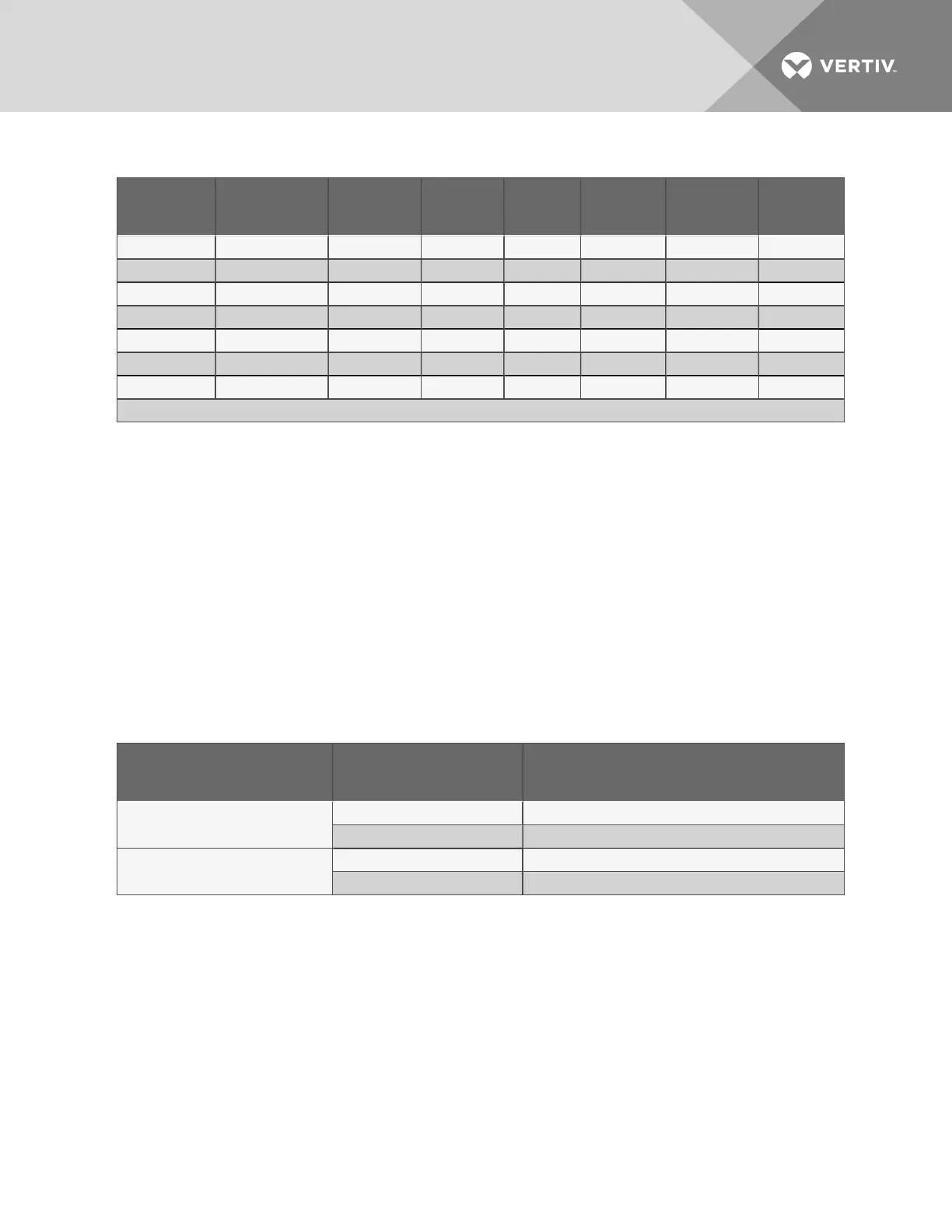

Copper Pipe

OD, in.

90 Degree

Elbow Copper

90 Degree

Elbow Cast

45 Degree

Elbow

Tee

Gate

Valve

Globe

Valve

Angle

Valve

1/2 0.8 (0.24) 1.3 (0.39) 0.4 (0.12) 2.5 (0.76) 0.26 (0.07) 7.0 (2.13) 4.0 (1.21)

5/8 0.9 (0.27) 1.4 (0.42) 0.5 (0.15) 2.5 (0.76) 0.28 (0.08) 9.5 (2.89) 5.0 (1.52)

3/4 1.0 (0.3) 1.5 (0.45) 0.6 (0.18) 2.5 (0.76) 0.3 (0.09) 12.0 (3.65) 6.5 (1.98)

7/8 1.45 (0.44) 1.8 (0.54) 0.8 (0.24) 3.6 (1.09) 0.36 (0.1) 17.2 (5.24) 9.5 (2.89)

1-1/8 1.85 (0.56) 2.2 (0.67) 1.0 (0.3) 4.6 (1.4) 0.48 (0.14) 22.5 (6.85) 12.0 (3.65)

1-3/8 2.4 (0.73) 2.9 (0.88) 1.3 (0.39) 6.4 (1.95) 0.65 (0.19) 32.0 (9.75) 16.0 (4.87)

1-5/8 2.9 (0.88) 3.5 (1.06) 1.6 (0.48) 7.2 (2.19) 0.72 (0.21) 36.0 (10.97) 19.5 (5.94)

Refrigerant trap = Four times equivalent length of pipe per this table

Table 2.6 Equivalent lengths for various pipe fittings, ft (m)

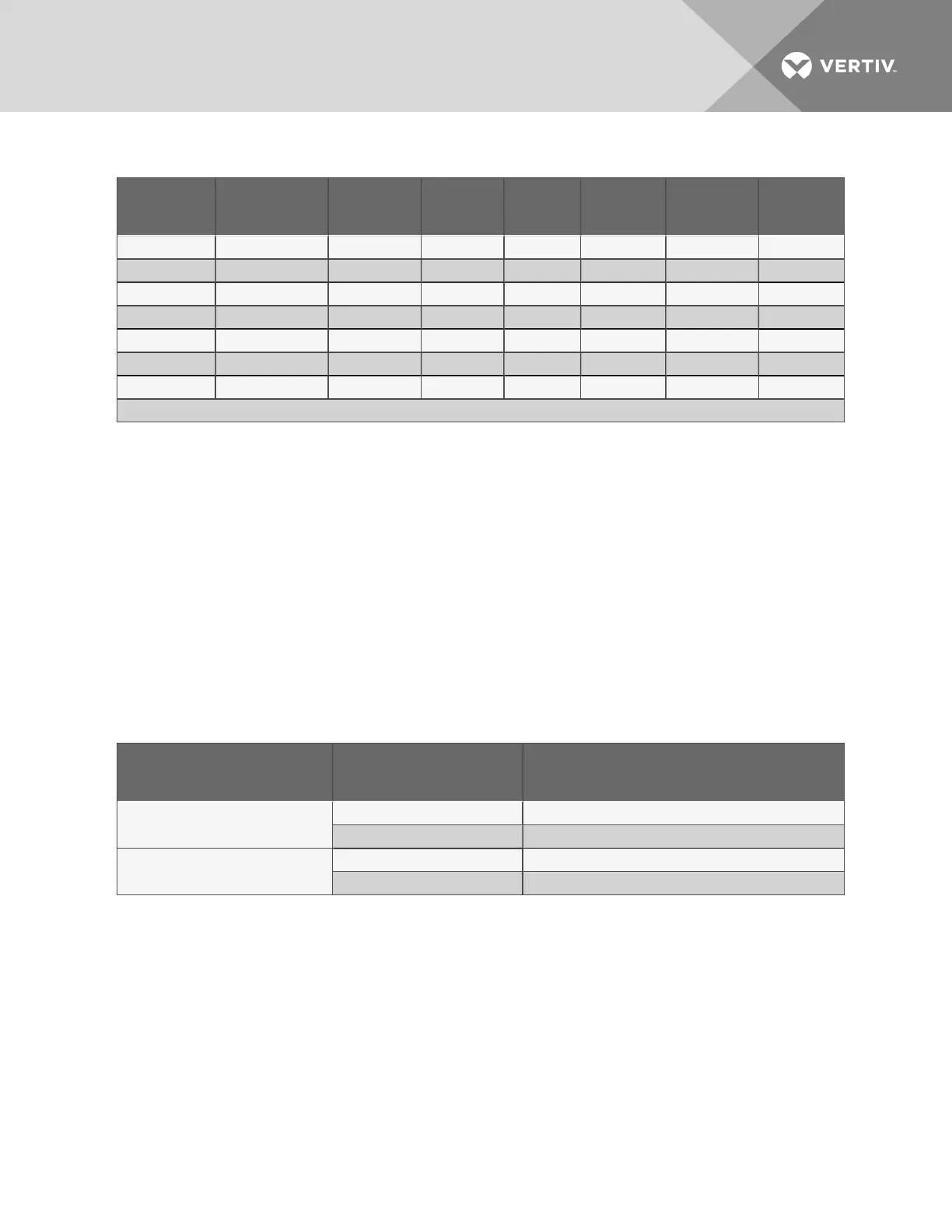

2.5.2 Pre-Charged Line Sets

Liebert® pre-charged line sets are available in 15 ft. (4.5m) and 30 ft. (9m) lengths (see Table 2.7 below).

NOTICE

Risk of improper handling and installation of pre-charged lines. Can cause kinks and similar damage to

lines.

Care must be taken to prevent kinking the pre-charged lines for 1-ton and 3.5-ton units.

Use tube benders and make all bends before making connections to either end of the pre-charged pipes.

Coil any excess tubing in a horizontal plane with the slope of the tubing toward the condensing unit. Use a

soft, flexible material to pack around the tubes when sealing openings in walls to prevent tube damage

and to reduce vibration transmission.

Line Size,

in.

Length,

ft. (m)

Charge R-407C,

lb-oz (kg)

3/8 liquid

15 (4.5) 0-5 (0.14)

30 (9) 0-10 (0.28)

5/8 or 7/8

suction

15 (4.5) 0-5 (0.14)

30 (9) 0-10 (0.28)

Table 2.7 Refrigerant charge in Liebert pre-charged R-407C line sets

2.5.3 Field-Fabricated Line Sets

All field-fabricated refrigeration piping should be copper piping, brazed using a brazing alloy with a

minimum temperature of 1350°F (732°C), such as Sil-Fos. Use a flow of dry nitrogen through the piping

during brazing to prevent formation of copper oxide scale inside the piping. Avoid soft solders such as

50/50 or 95/5.

Use the sweat adapter kits to terminate the piping at each unit end. Consult factory representatives to

obtain the proper sweat adapter kit. Liebert® PFH unit charge levels and coupling size on the next page

has PFH unit connection sizes. Use Recommended line sizes, OD Cu on page19 for recommended line

sizes.

Vertiv | Liebert PFH Installer/User Guide | 17

Loading...

Loading...