EL – Owner’s Manual – Rev.00 – September 2021 11

Material

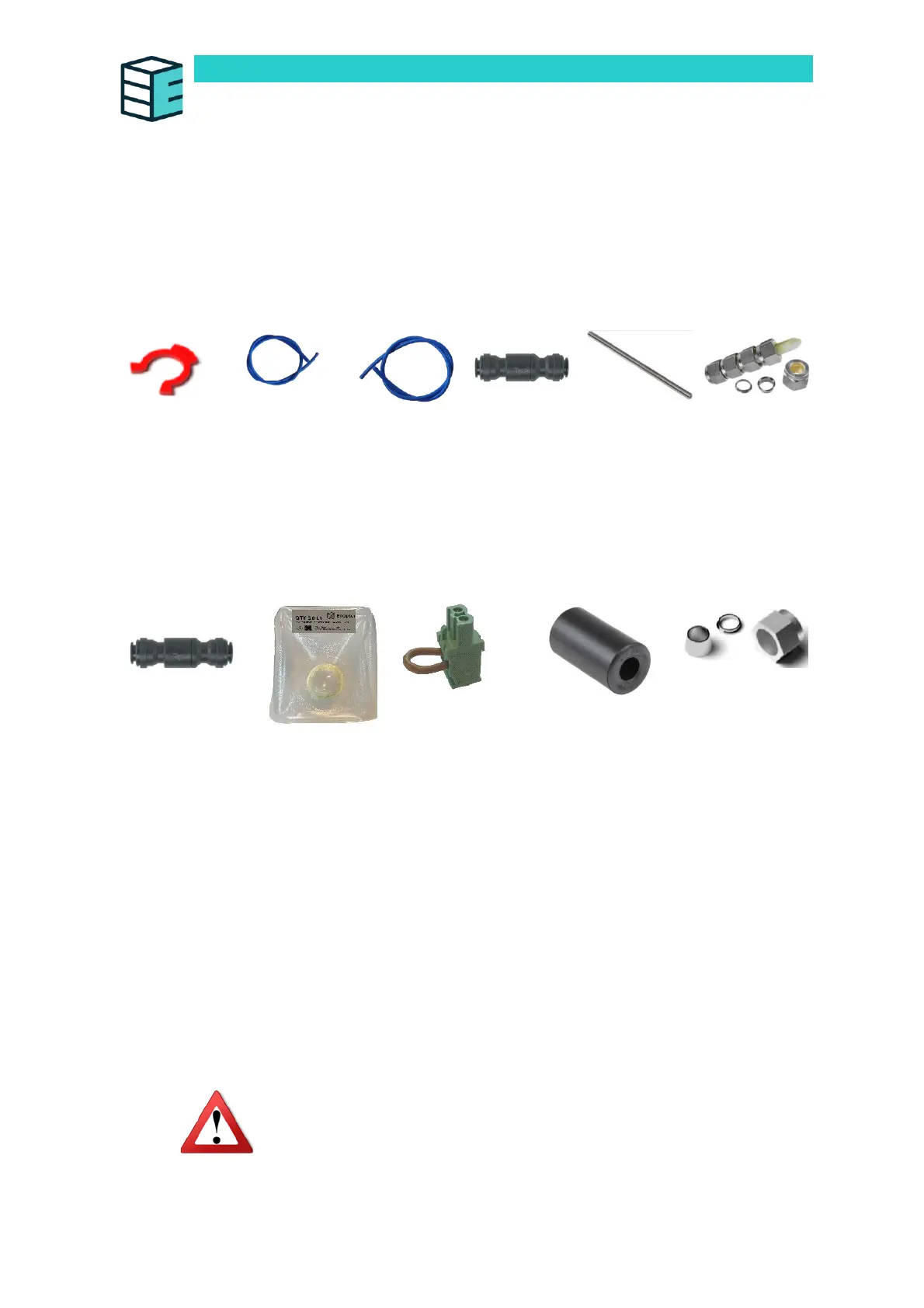

• Push-fit locking clips (8 mm + 10 mm)

• 8 mm + 10 mm diameter LDPE tubing (ensure the 8 mm tubing is pressure-resistant to at least

4 bar!)

• Stainless steel AISI 136- ASTM A269 -¼” outside diameter X 0,89 mm w.t.

Accessories (included in the box)

• 10mm Check Valve **only needed when connecting multiple electrolysers in parallel**

• Electrolyte filling bag (labelled)

• Dry contact jumpers

• Ferrite cylinder for power input cable

• Swagelok Nut and Ferrule set

IMPLEMENTING SYSTEM SAFETY

Each connection to and from the device must be inspected and tested. Additional system engineering

might be required to ensure safe operation.

Always follow best practices, apply your local codes of regulation (if applicable), and follow industry

standards for the implementation of safety systems to manage the risks of running electrolysers and

storing hydrogen.

Gas containing pipes must be properly connected to the specific ports, tested by the operator, and

directed to separate safe areas. If this is not possible, the operator must find another safe solution,

such as using a flare stack, burn box, or forced dilution. When forced dilution is utilised, all components

used in this process must not be able to ignite the hazardous substances.

Warning!

It is the operator’s responsibility to ensure good engineering practices are

applied to the hazardous substances which are released during the operation

of the device!

The operator must ensure that the outlets satisfy all relevant local rules and

regulation, in terms of noise emission, risk assessments, maintenance and all

other relevant areas.

Loading...

Loading...