EL – Owner’s Manual – Rev.00 – September 2021 15

Never obstruct the output of the purge – do not place any check valves, or other

system components which might block or close the line. Make sure that no obstacles

including the purged water and ice are blocking the line. It must always be at

atmospheric pressure. If necessary, use a water trap and heater to avoid pressure

from building up.

Please be aware that when larger hydrogen systems are created by putting together

several modules, the piping downstream may have to be sized accordingly. It is the

operator’s responsibility to ensure adequately sized piping is selected, which does

not limit the air flow. The operator must ensure that the outlet satisfies all relevant

local rules and regulation, in terms of noise emission, risk assessments, maintenance,

and all other relevant areas.

Attention!

If a backpressure inside the line builds up, the device will get permanently

damaged.

Enapter is not responsible for any damage caused to the device from mismanaged

piping arrangements.

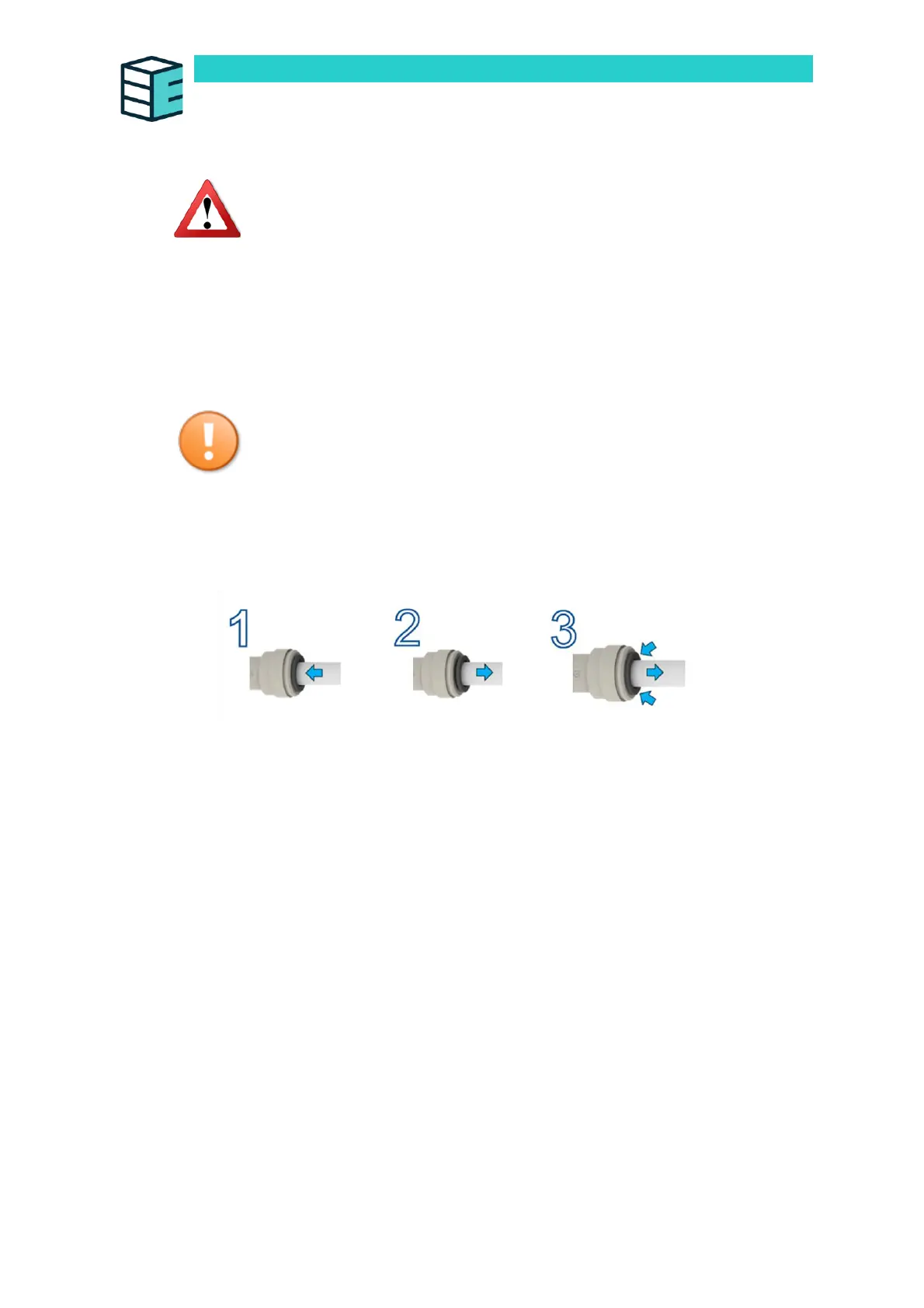

INSTRUCTIONS FOR CONNECTING PLASTIC TUBES

1. Cut the tube perpendicular to the axis and remove sharp edges. Ensure the outside diameter

is free of score marks, and the cut is perpendicular across the tube. Fully insert the tube into

the fitting. The inserted pipe diameter must match the fitting.

2. Pull the tube to check it is firmly held in place, then secure the connection by inserting a red

fastening clip.

3. To disconnect, ensure that the line is depressurised. Then, remove the red fastening clip and

push the collet against the fitting, while simultaneously pushing the tube into the fitting.

Holding the collet in this position, pull the tube out of the fitting in one smooth motion.

Loading...

Loading...