EL – Owner’s Manual – Rev.00 – September 2021 1

OVERVIEW OF THE ELECTROLYSER

Enapter’s patented anion exchange membrane (AEM) electrolyser is a standardised, stackable, and

flexible device to produce hydrogen. The modular, easily maintainable design – paired with advanced

software integration – allows set up in minutes and remote control and management.

Specifications

The specifications of the electrolyser can be found in the datasheet. It can be downloaded here:

Datasheet of the electrolyser.

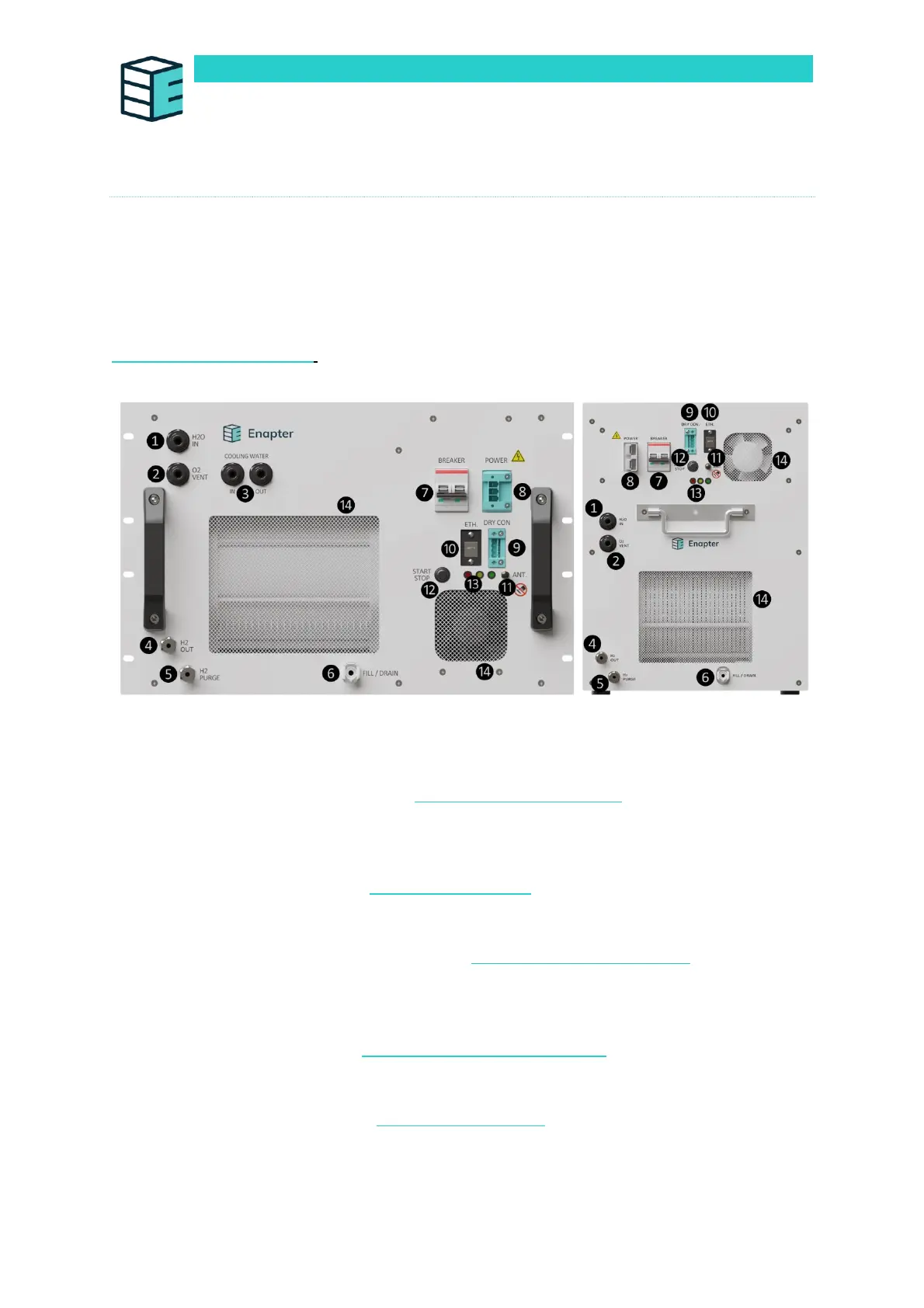

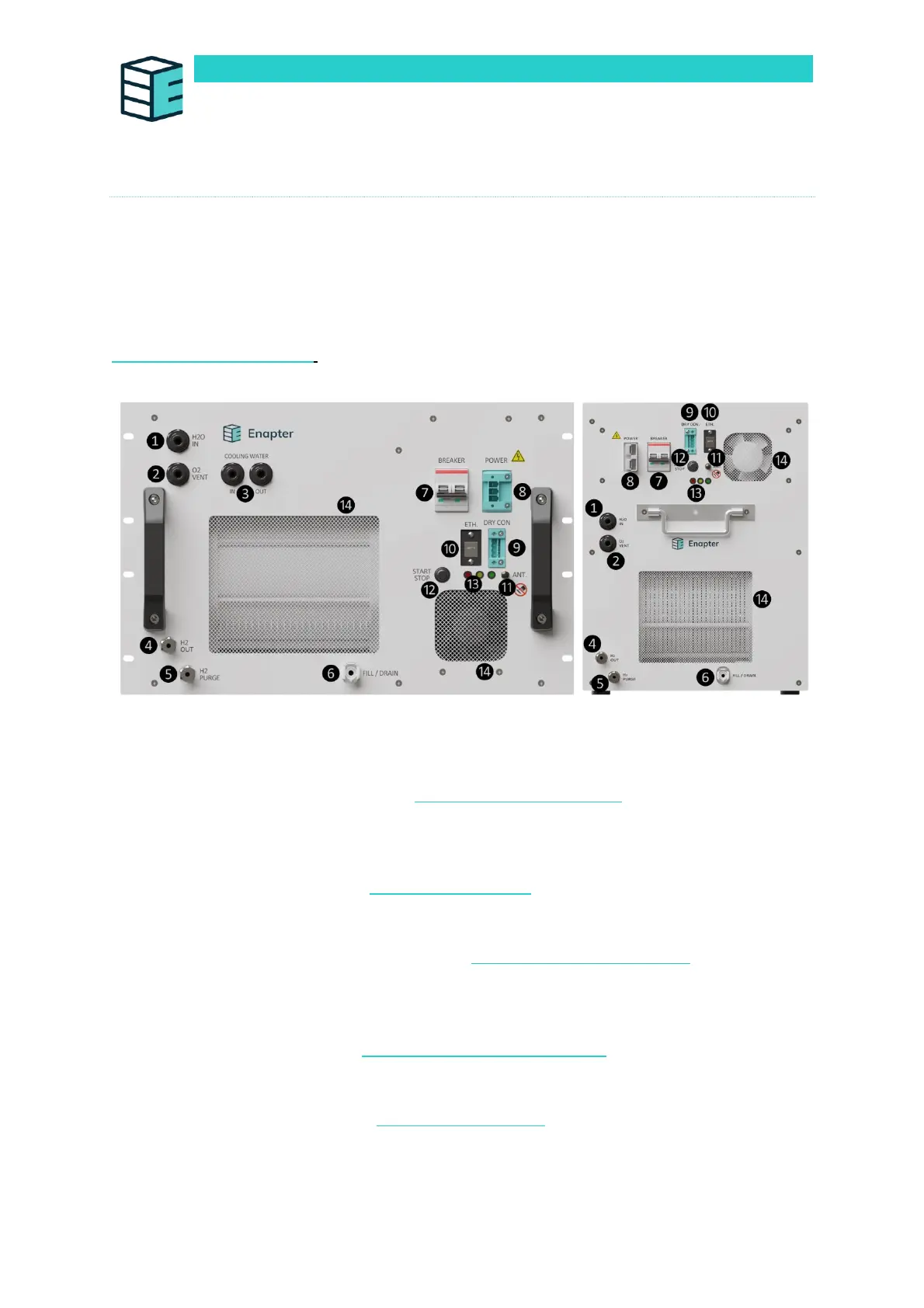

Front Panel

The front panel of the electrolyser includes all physical connections of the device.

1. H

2

O In – please refer to the section Water Inlet Connection Guide

• Push-fit female bulkhead connector (8mm outer diameter pipes)

• Input: Filtered water input with a conductivity < 20 µS/cm at 25°C, input pressure

between 1 and 4 bar

2. O

2

Vent – please refer to the Vent Connection Guide

• Push-fit female bulkhead connector (10mm outer diameter pipes)

• Output: O

2

with water vapour and traces of H

2

3. Cooling Water IN/OUT – please refer to the Cooling Loop Connection Guide

• Only available in the liquid cooled electrolysers (LC versions)

• Push-fit female bulkhead connector (10mm outer diameter pipes)

• Input/Output: cooling water to cool down the device

4. H

2

Out – please refer to the Hydrogen Outlet Connection Guide

• ¼" double ferrule Swagelok tube fitting bulkhead (SS-400-61)

• Output: 500 NL/hr of H

2

, up to 35 barg

5. H

2

Purge – please refer to the Purge Connection Guide

• ¼" double ferrule Swagelok tube fitting bulkhead (SS-400-61)

• Output: Periodical purge of up to 20 NL, H

2

and water

Loading...

Loading...