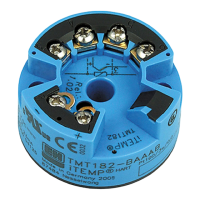

Use in safety instrumented systems Temperature transmitter iTEMP TMT82

26 Endress+Hauser

In the case of a commissioning check, observe the following in addition to test

sequences A and B:

If both of the transmitter's input channels are used, the two-channel functions such as

Sensor drift or Backup (channel assignment at current output) must also be tested.

If thermocouples are used, the setting for the Reference junction option and its preset

value must be checked.

The function of the "Out of range category" must be tested to its limits, 3.8 mA or 20.5 mA.

The operational state of the transmitter must be checked (SIL mode).

5.4.1 Test sequence A

1. Two-point calibration

Test the current output by applying the reference temperature at the sensor or a

corresponding reference signal (resistance, voltage) at 2 points. Select 4 to 6 mA for

lower-range value and 18 to 20 mA for upper-range value.

The measurement results must be within the specified safety inaccuracy range.

Otherwise the test has not been passed.

2.

A0053707

3 Trigger a device restart using the appropriate function in the operating tool used or via HART

command 42.

Check the safe state (High and Low alarm). If the transmitter's hardware or software

write protection is enabled, switch it off first.

Check both alarm states (High and Low) by restarting the device using the

appropriate function in the operating tool used or via HART command 42.

The alarm states, High alarm (≥ 21.0 mA) and Low alarm (≤ 3.6 mA), are output

consecutively for longer than 4 s in each case.

Both current values must be checked.

96% of dangerous, undetected failures are detected using this test (proof test coverage,

PTC = 0.96). During the test sequence, the device's current output typically behaves as

illustrated in → 6, 28.

5.4.2 Test sequence B

1. Two-point calibration

Test the current output by applying the reference temperature at the sensor or a

corresponding reference signal (resistance, voltage) at 2 points. Select 4 to 6 mA for

the lower-range value and 18 to 20 mA for the upper-range value.

The measurement results must be within the specified safety inaccuracy range.

Otherwise the test has not been passed.

Loading...

Loading...