Section 12 Confi

uration 56

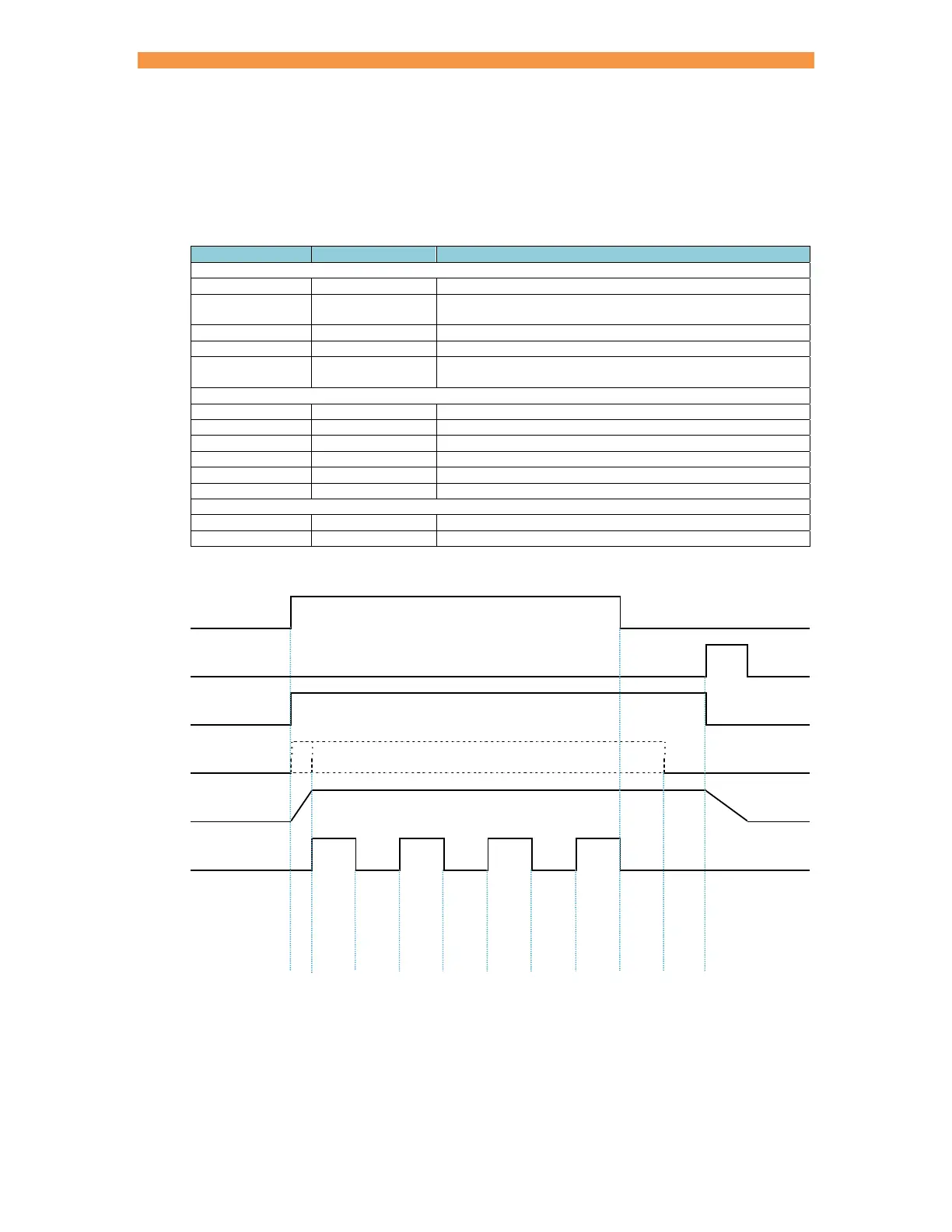

Seam pulsation

Seam pulsation can be used in applications where a continuous weld is not required. The Main heat and the

Cool2 intervals are repeated for the duration of the weld. The following example shows how this type of sequence

may be implemented.

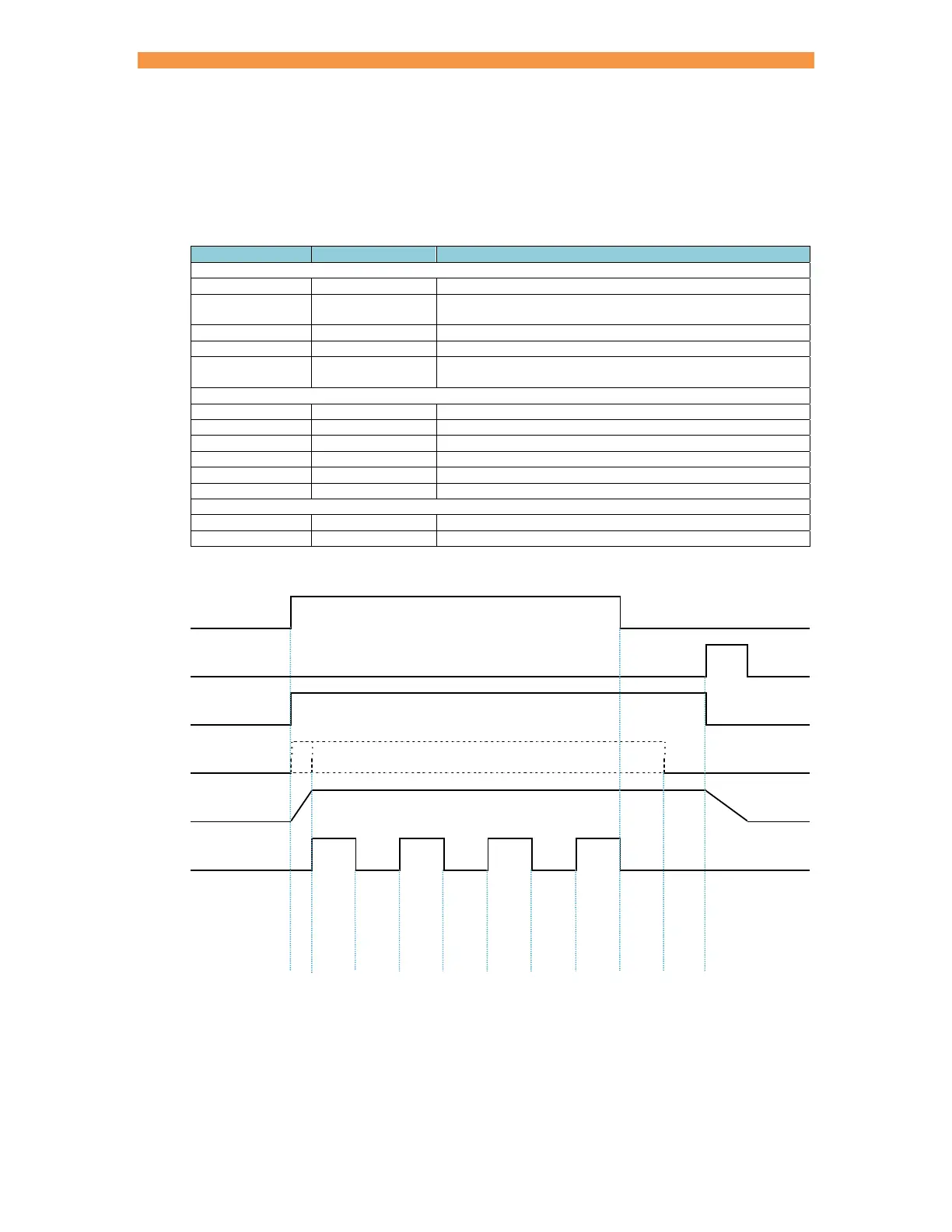

Parameter Setting Description

Sequence timing

Presqueeze ms The time for the electrodes to close onto the work piece.

Squeeze ms The time between the initial application of the electrode force

and the first application of welding current

Main heat ms The main welding current is applied

Cool2 ms The material is allowed to cool with electrode force applied

Hold ms Electrode force continues after the welding current has

finished

Current control

Main mode P/W – CCu – CCC Operating mode of the Main heat interval

Main heat % The % heat used during the Main heat interval

Main current kA The current used during the Main heat interval

Main monitor

1

yes/no The current can be tested between limits

Low limit

1

% Current low limit

High limit

1

% Current high limit

Options

Pre-heat no Disable the Pre-heat parameters

Post-heat no Disable the Post-heat parameters

1

optional

Start input

1

EOS output

WAV output

Motor output

2

Force

Current

Interval

S

ueeze

Main

heat

Cool2

Main

heat

Cool2

Main

heat

Cool2

Main

heat

Cool2

Hold

1

The Main heat – Cool2 intervals are repeated until the Start input is removed.

2

The operation of the motor output is determined by the 2

nd

stage test (Section 12 Configuration).

Loading...

Loading...