EMW90HDNC1U Air-cooled Chiller

damage is found, please report it to the seller

with the barcode number on the outside of the

package within one week.

Please count the number of units and

installation accessories according to the list of

accessories.

Before disposing of the packaging materials,

please make sure that there are no loose parts

in the packaging materials. In order to protect

the environment, it is recommended to recycle

the packaging boxes.

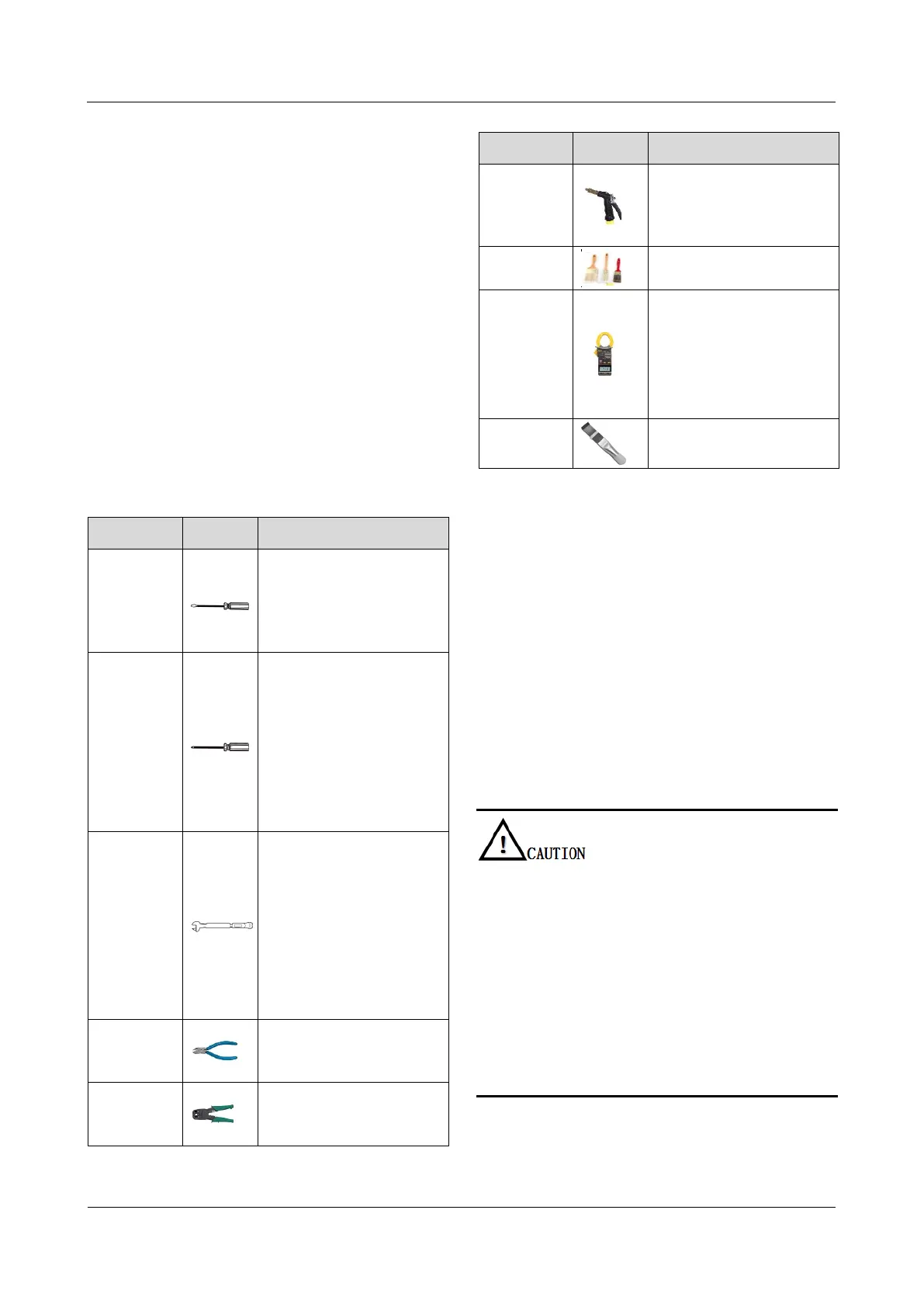

3.2.2 Tools Preparation

Before installation and maintenance, please

prepare not limited to the commonly used tools

listed in Table 3-2. On-site technicians can

increase or decrease them according to the

actual situation.

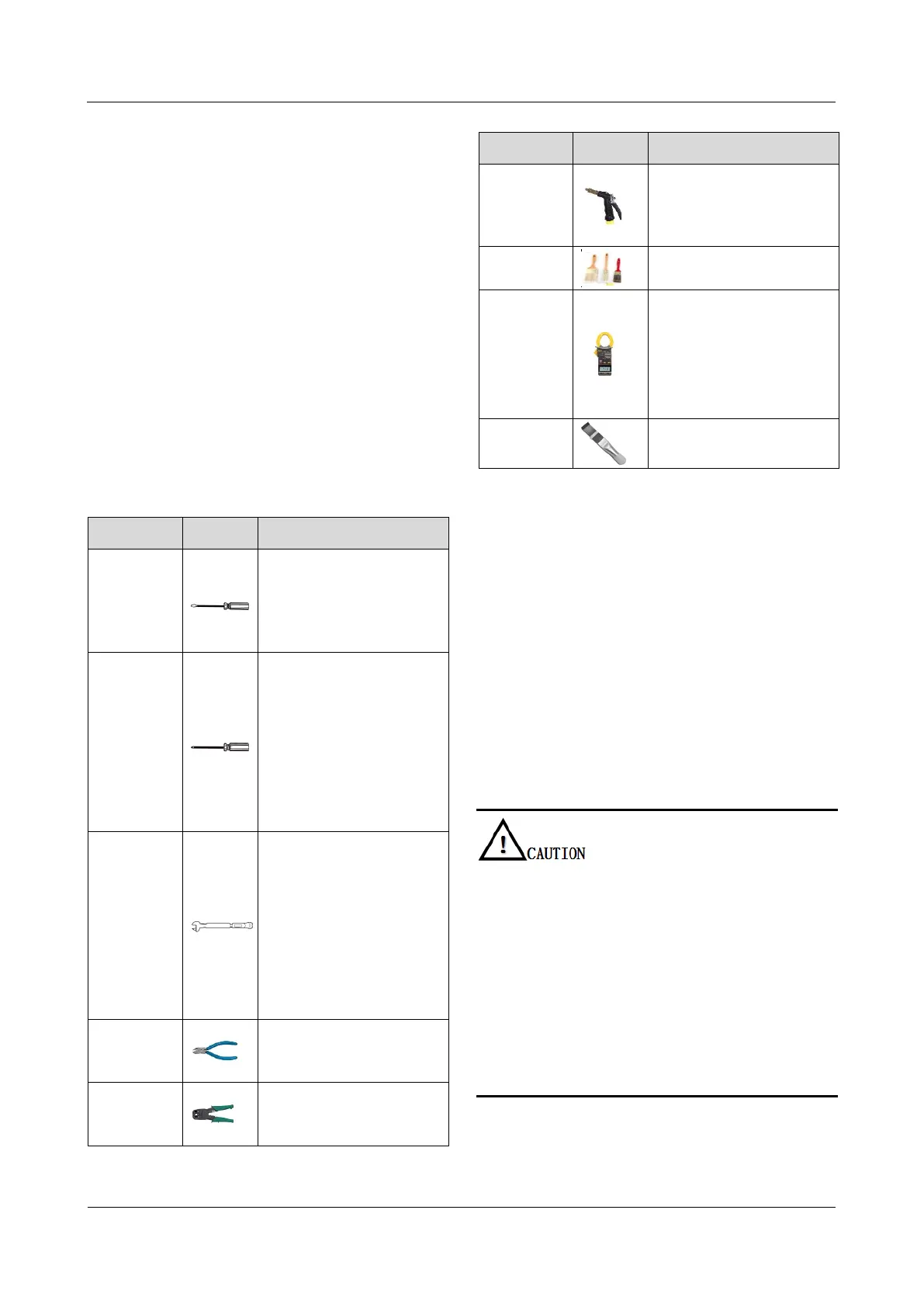

Table 3-2 Commonly used tools

Tool Icon Function

Flat-blade

screwdriv

er

(2mm×75

mm)

A flat-blade screwdriver

installs or removes the

connecting wires of the

controller, etc.

Phillips

screwdriv

er

(M3/M4/M

5/M6)

Phillips screwdriver is

used to install or

remove screws for other

parts. Recommended

tightening torques are

as follows:

M3: 0.5N.m, M4:

1.2N.m, M5: 2.7N.m,

M6: 4.2N.m

Torque

wrench

(Setting

value:

5~25N.m,

scale:

0.25N.m)

Used for disassembly

and assembly of screws

and pipeline

connection, etc.

Tightening torque of

screws: 13N.m (M8)

Tightening torque of

chuck connection:

10N.m

Diagonal

pliers

remove the cable ties

on site.

Crimping

pliers

On-site processing of

cables and crimping of

various terminals.

Tool Icon Function

r special

cleaning

water gun

Clean the condenser of

the air conditioning

system.

Brush

Clean up dust.

Clamp

ammeter

Check the working

voltage and current on

site.

Check the internal

power distribution

voltage and current.

Fin comb

Corrects bent and

deformed fins.

3.3 Mechanical Installation

Prerequisites

The installation location of the chiller has been

reasonably planned by referring to 3.1.2

Physical Dimension, 3.1.3 Installation

Environment and 3.1.4 Installation Layout.

The packaging of the chiller has been

disassembled, and the installation tools and

accessories listed in the packing list are ready.

The coolant pipelines (diameter: DN28, pipeline

pressure ≥ 3.5bar) have been prepared.

Precautions

The pull ring on the front of the chiller is only used for

pulling the maintenance panel. It is forbidden to use it

as a force support to move the chiller upwards.

To avoid condensation, use insulated and thermal

insulated pipes for connection.

The coolant inlet and outlet of the chiller adopts quick

connectors, and the specifications of the connecting

pipes must conform to the specifications of the coolant

inlet and outlet ports.

It is suggested to install stop valves between the inlet

and outlet connecting pipes of the chiller and the

equipment to be cooled, so as to maintain the chiller or

the equipment to be cooled later.

Loading...

Loading...