EMW90HDNC1U Air-cooled Chiller

Prerequisites

The power has been cut off for at least 10

minutes.

The Phillips screwdriver and flat-blade

screwdriver have been prepared by referring

to Table 3-1.

Background

The electrical components (such as control board,

etc.) of the EMW90HDNC1U chiller are centrally

arranged in the electrical control box, and users

can maintain and replace the relevant

components according to the actual plan.

Procedure

Step 1 Remove the entire chiller and place it in an

area with sufficient maintenance space.

Step 2 Remove the maintenance panel and the

electric control box cover plate above the

chiller in sequence.

Step 3 Remove the fixing screws and wiring

terminals of the corresponding electrical

components according to the plan.

Step 4 Take out the electrical components for

replacement.

Step 5 Install in the reverse order of Step 3 to

Step 1 to complete the parts

replacement.

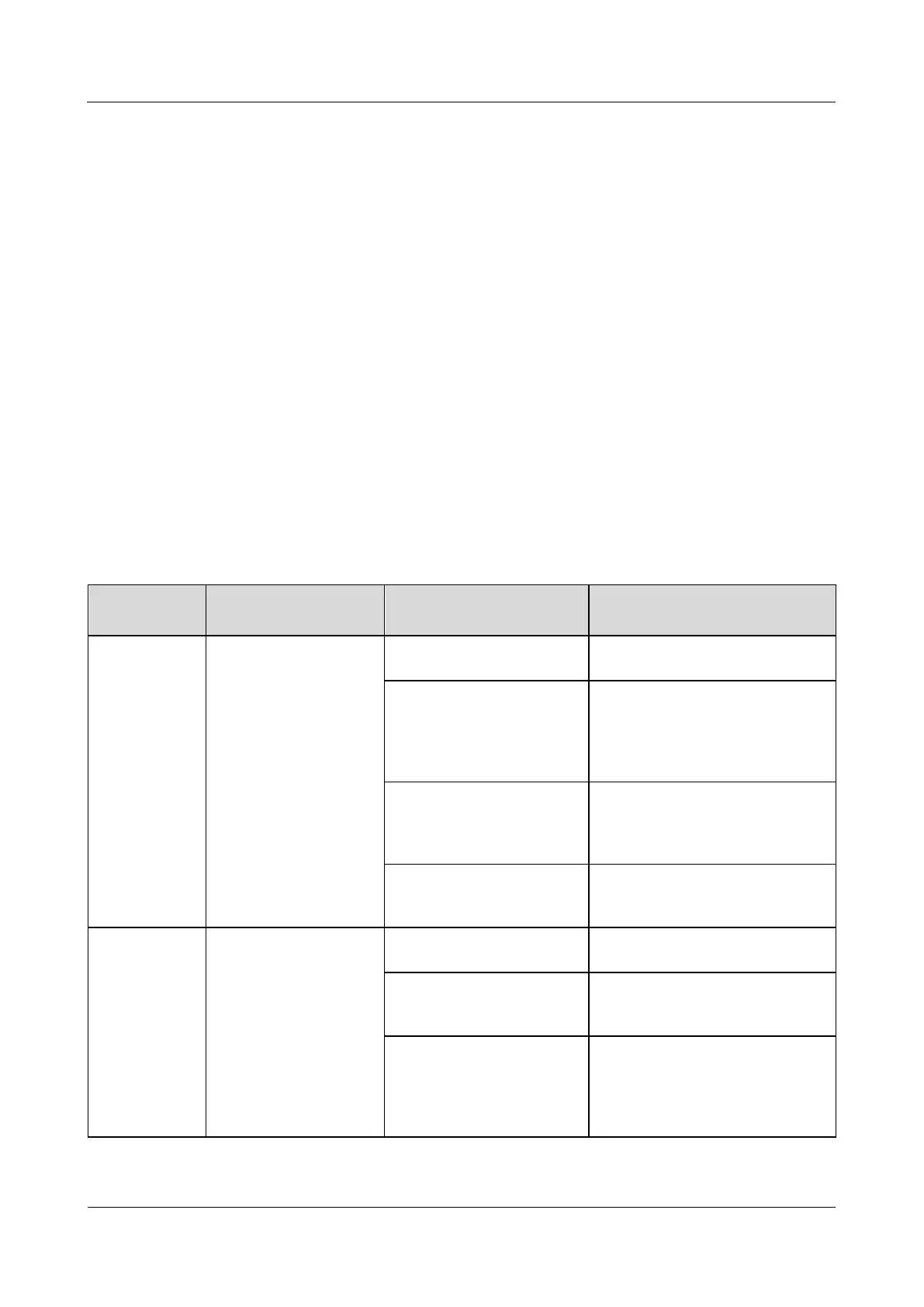

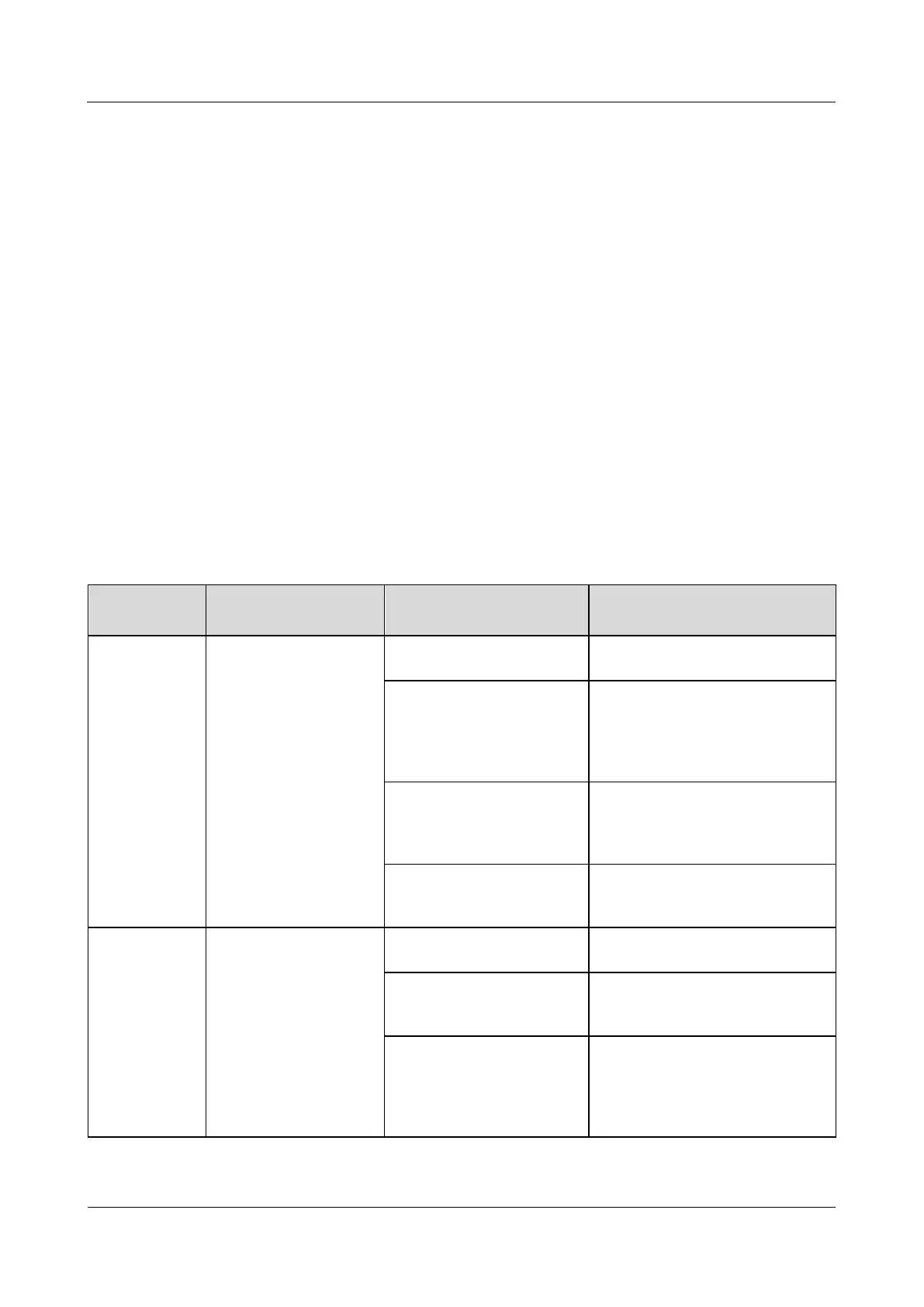

7.5 Alarm Handling

The alarm information of EMW90HDNC1U chiller is shown in Table 7-4.

The locking alarm (such as "System High Pressure Alarm Locking") needs to be manually released

by first powering off the chiller and then powering on the chiller, and other alarms will be automatically

released when the current scene does not meet the alarm conditions.

Table 7-4 Alarm list

Alarm Name

Generation

Condition

Possible Causes Processing Method

High Temp Of

Outlet Water

Outlet coolant

temperature is higher

than high temperature

set threshold.

temperature probe failure.

Replace the outlet coolant

temperature probe.

Abnormal operation of

compressor, electronic

expansion valve, internal

circulating coolant pump

or external fan.

Check the compressor,

electronic expansion valve,

internal circulating coolant

pump and external fan.

The load of the equipment

to be cooled exceeds the

design cooling capacity of

the chiller.

Check the load of the

equipment to be cooled.

in the cooling medium

circulation system.

Check the leakage point and

replenish the cooling medium

after repair.

Low Temp Of

Outlet Water

The outlet coolant

temperature is lower

than low temperature

set threshold.

temperature probe failure.

Replace the outlet coolant

temperature probe.

Malfunction of electric

heating tube or internal

circulation pump.

Check the electric heating tube

and internal circulating coolant

pump.

equipment to be cooled

exceeds the designed

heating capacity of the

chiller.

Check the heat leakage of the

equipment to be cooled.

Loading...

Loading...