REV. 09/2022

4

D

Table 1 Lubricants

Code Type Specication Amount Position

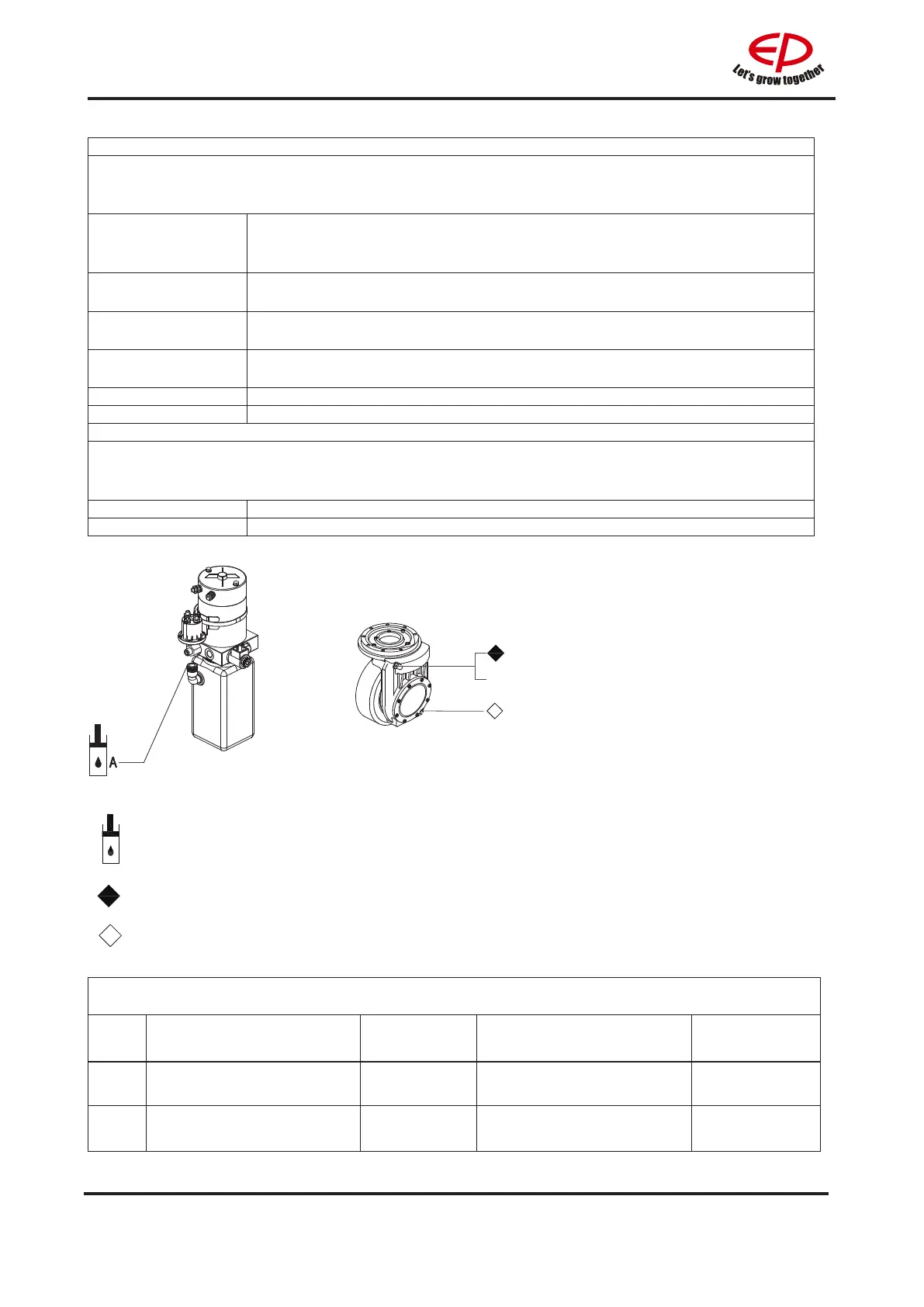

A

Anti-wear hydraulic oil L-HM32 0.48 L

Hydraulic

System

B

Heavy duty gear oil 85W-90 GL-5 1500ml Gearbox

B

1000-hour/6-month maintenance

After operating for 1000 hours in total, the truck should also be maintained according to the

following procedures in addition to the 50-hour maintenance, 250-hour maintenance and 500-

hour maintenance mentioned above

27 Inspect whether the bearing capacity reaches the rated load and

implement corresponding adjustment through the ood valve adopted in

the hydraulic station

28 Inspect whether all the labels are clear and intact

29 Check if there is abrasion between shaft and bearing of front and rear

fork.

30 Check if there is deformation or Check if there is deformation or fracture

on the upper and down connecting rod.

31 Check for looseness of each joint.

32 Add lubricating grease to the pin roll.

2000-hour/12-month maintenance

After operating for 2000 hours in total, the truck should also be maintained according to the

following procedures in addition to the 50-hour maintenance, 250-hour maintenance, 500-

hour maintenance and 1000-hour maintenance mentioned above

30 Check hydraulic oil level.

31 Replace hydraulic oil.

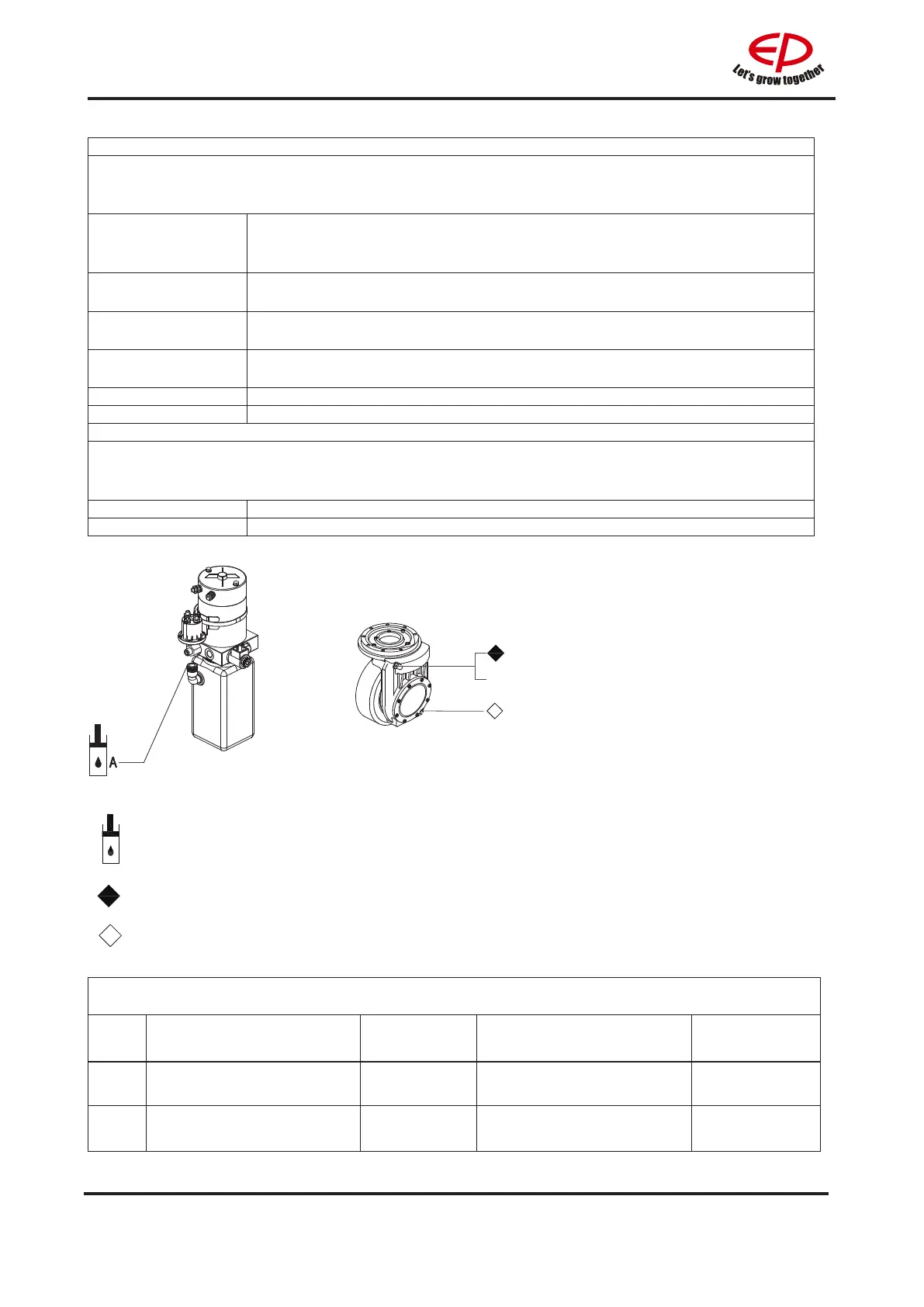

Gear oil discharge nozzle

Hydraulic oil injection nozzle

Gear oil injection nozzle

Loading...

Loading...