35

Error

Cause Solution

Pipette is dripping;

the volume

dispensed is

incorrect.

– The tip may be loose.

– There may be foreign

matter between the

pipette and the tip.

– The piston, nose cone and

cylinder may be damaged

or contaminated.

– The lower part may be

loose.

– For multi-channel model:

The O-ring may be

damaged.

– Attach the tip firmly. Make sure that

an Eppendorf tip is used.

– Wipe the pipette. Ensure that the tip

is protected from dust.

– Treat the lower half of the pipette as

described in Sec. 6 and Part B

"Ordering Information/service

parts".

Residual liquid is

in the tip;

dispensing is

incomplete.

– See above.

– The dispensing speed

may be too high.

– The incorrect pipetting

option may have been

selected.

– See above.

– The procedure for checking the

function is described in Sec. 5,

"Operation".

Motor stops

during the

dispensing

procedure.

– The battery may be run

down.

– The pipette may be

heavily contaminated.

– Discard the dispensing as it is

incorrect. Recharge the battery

(Sec. 3.3) or treat the pipette as

described in Sec. 6.

Multi-channel:

Pipette doesn’t

aspirate liquid.

(Continued

on next page)

The magnetic coupling on the

multi-channel lower part no

longer works.

In the case of the Research

pro Pipette 4860, strong

impact stress can result in a

separation of the magnetic

connection between the

spindle and the piston

actuator. As a result of this

separation, the pipette no

longer aspirates liquid, despite

movement of the motor.

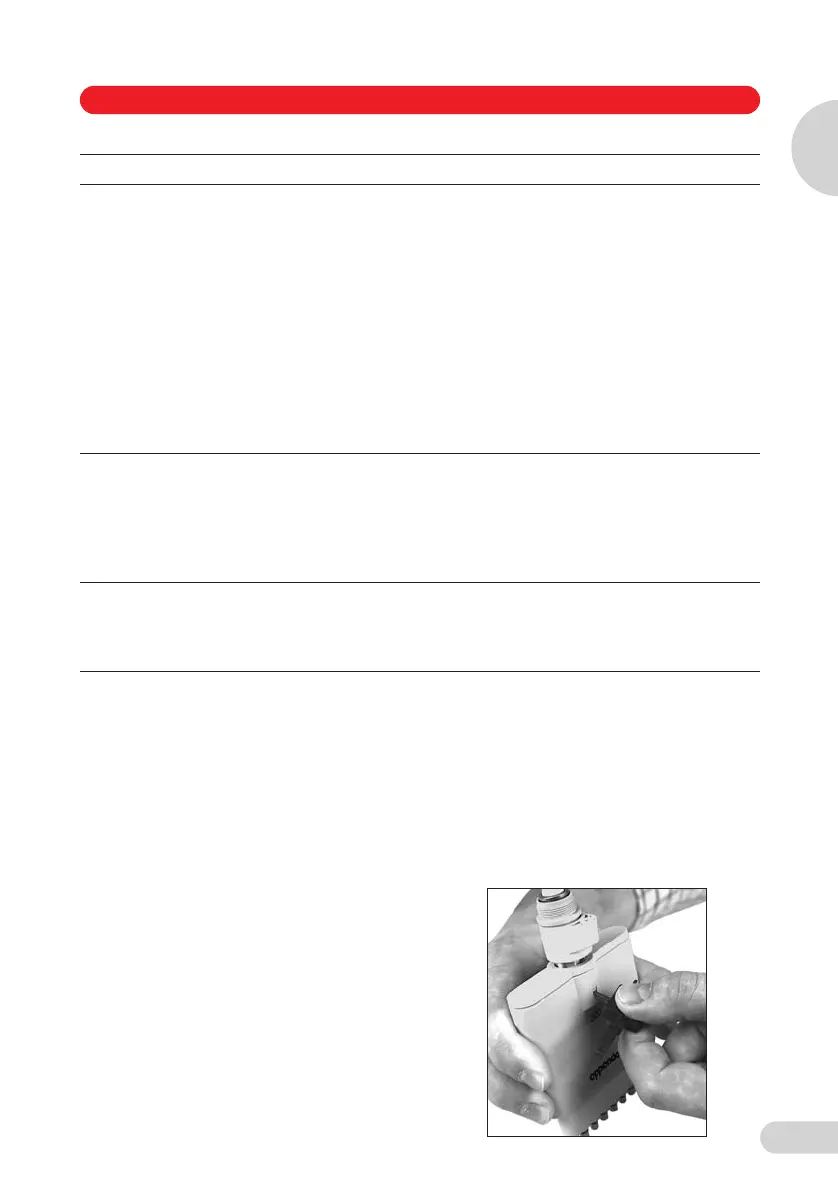

In order to reestablish the connection,

proceed as follows:

– Separate the ejector from the lower

part.

– To do this, press the lower part

against a surface until it springs in.

Simultaneously press the stop clutch

inward with side "B" of the universal

tool. The ejector cover panel springs

up.

Troubleshooting

7 Troubleshooting

7

1_E06 Pflege etc. Seite 35 Donnerstag, 9. Oktober 2008 7:21 19

Loading...

Loading...