PRINCIPLES

OF

OPERATION

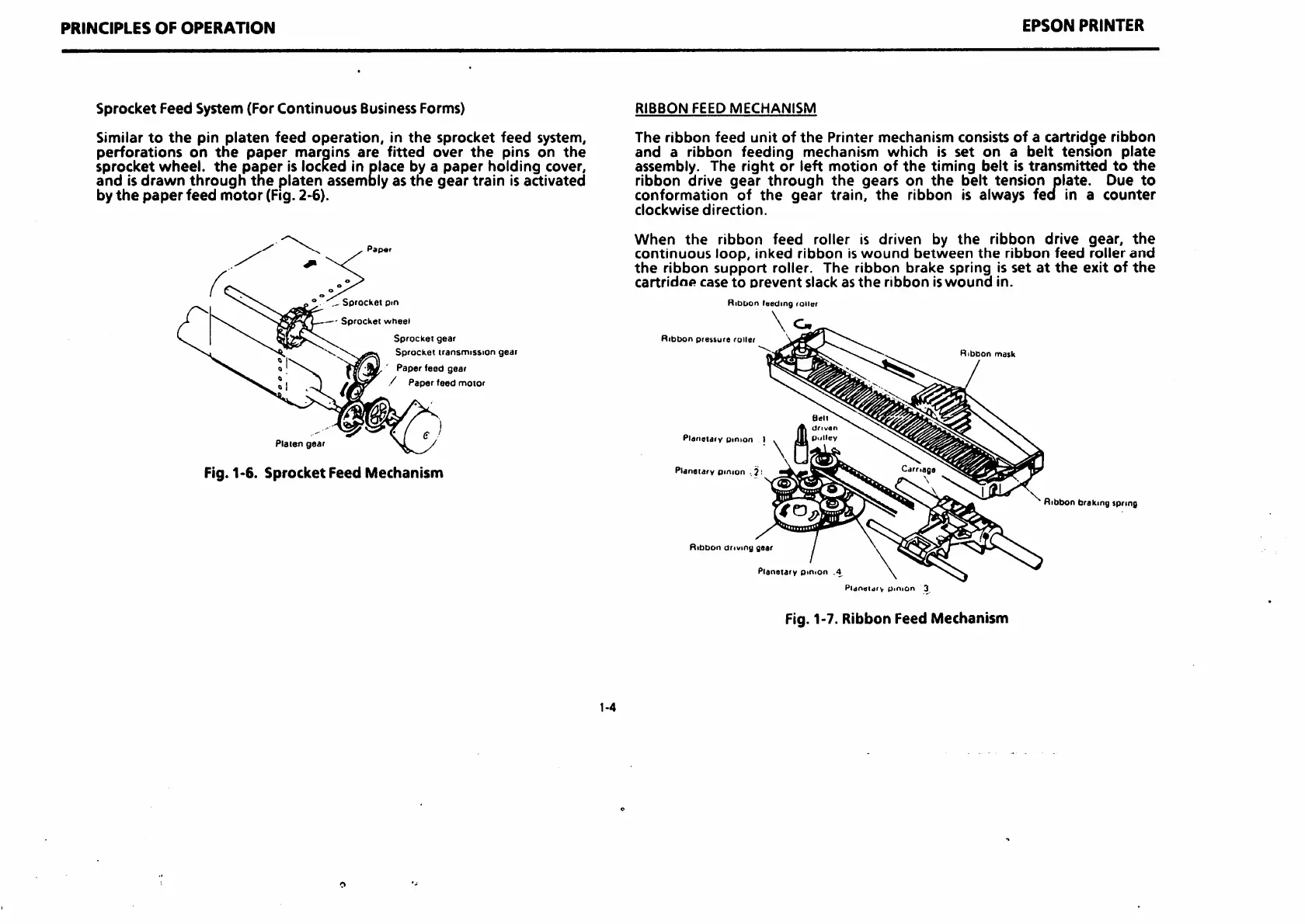

Sprocket

Feed

System (For

Continuous

Business Forms)

Similar

to

the

pin

platen

feed

operation,

in

the

sprocket

feed

system,

perforations

on

the

paper

margins

are

fitted

over

the

pins

on

the

sprocket wheel, the paper islocked in place bya paper holding

cover,

and

is

drawn

through the

platen

assembly

astne gear

train

is

activated

by

the

paper

feed

motor

(Fig. 2-6).

-

sprocket

pin

Sprocket

wrteel

Sprocket

gear

Sprocket

transmission

gear

Paper feed gear

/ Paperfeed motor

Platen

gear

Fig. 1-6.

Sprocket

Feed

Mechanism

1-4

EPSON

PRINTER

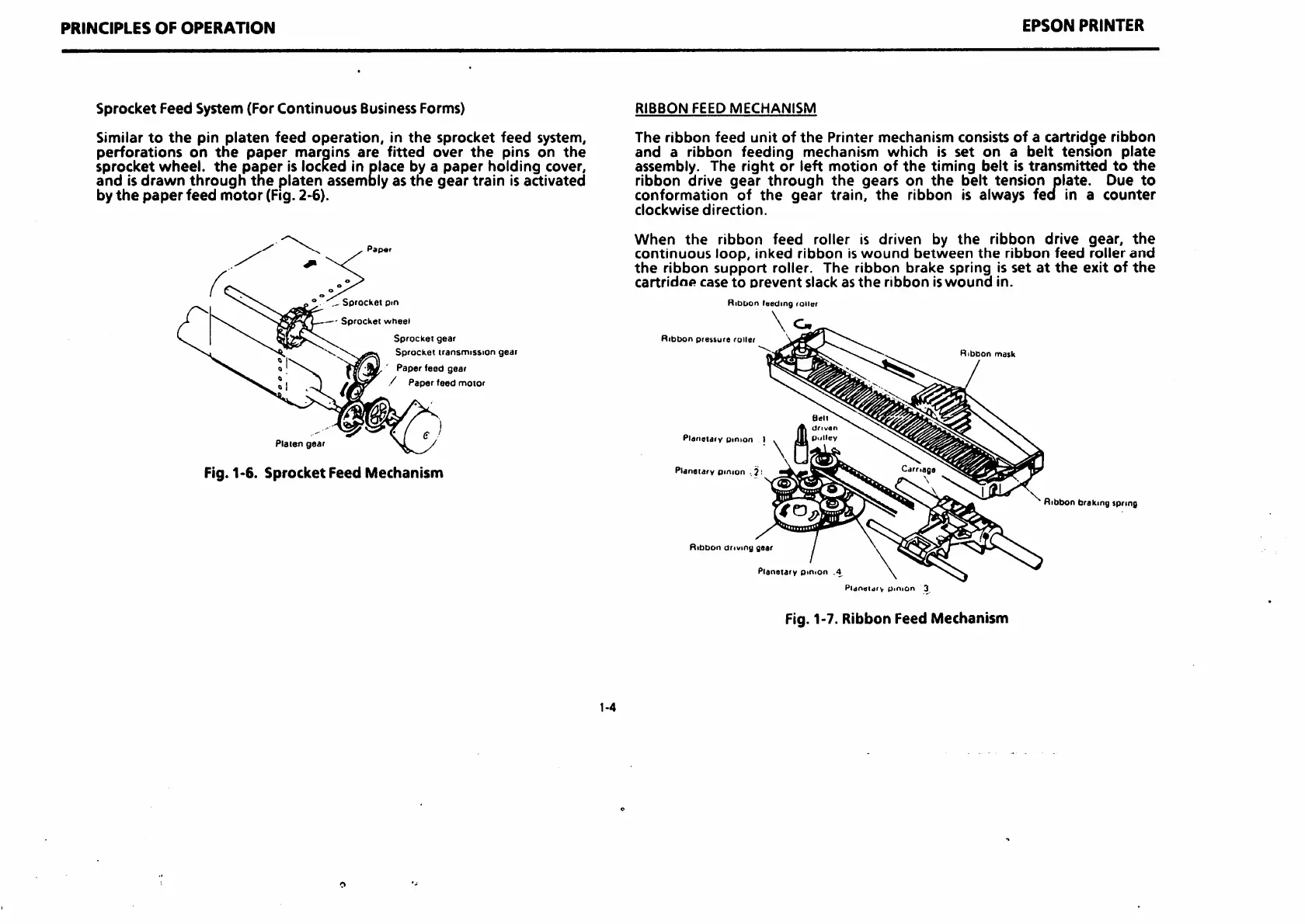

RIBBON

FEED

MECHANISM

The ribbon feed unit of the Printer mechanism consists of a cartridge ribbon

and

a

ribbon

feeding

mechanism

which

is

set

on

a

belt

tension

plate

assembly.

The

right

or

left

motion

of

the

timing

belt

is

transmitted

to

the

ribbon drive gear through the gears on the belt tension plate. Due to

conformation of the gear train, the ribbon is

always

fed in a counter

clockwise

direction.

When

the

ribbon

feed

roller is driven by

the

ribbon drive

gear,

the

continuous

loop, inked ribbon is

wound

between

the

ribbon

feed

roller

and

the

ribbon

support

roller.

The

ribbon

brake

spring is

set

at

the

exit

of

the

cartridop

case

to

prevent

slack

as

the

ribbon

is

wound

in.

Ribbon

laading

roller

\o,

Ribbon

pressure

roller

Ribbon

mask

Planstdry

pmiori

I

Planatary

pmion

..

Ji

Ribtwn braking spring

Ribbon

driving

gear

Planetary

pmion

.4

Pldneidty

pinion

3

Bell

drivan

Iley

Carriage

Fig. 1-7. Ribbon Feed Mechanism

Loading...

Loading...