EPSON

PRINTERS

PAPER

FEED

MECHANISM

The

Model

3510/3560

mechanisms

are

adaptable

for

use

with

different

paper

types. The Model 3510 has

three

paper

feed options: friction, pin platen, or

sprocket

feed,

and

utilizes

three

paper

types: roll,

cut

sheet,

or continuous

business

form.

The Model 3560

operates

with

both

friction

and

sprocket feed,

and

may be

used

with

continuous

business

forms

or

cut

sheet

paper.

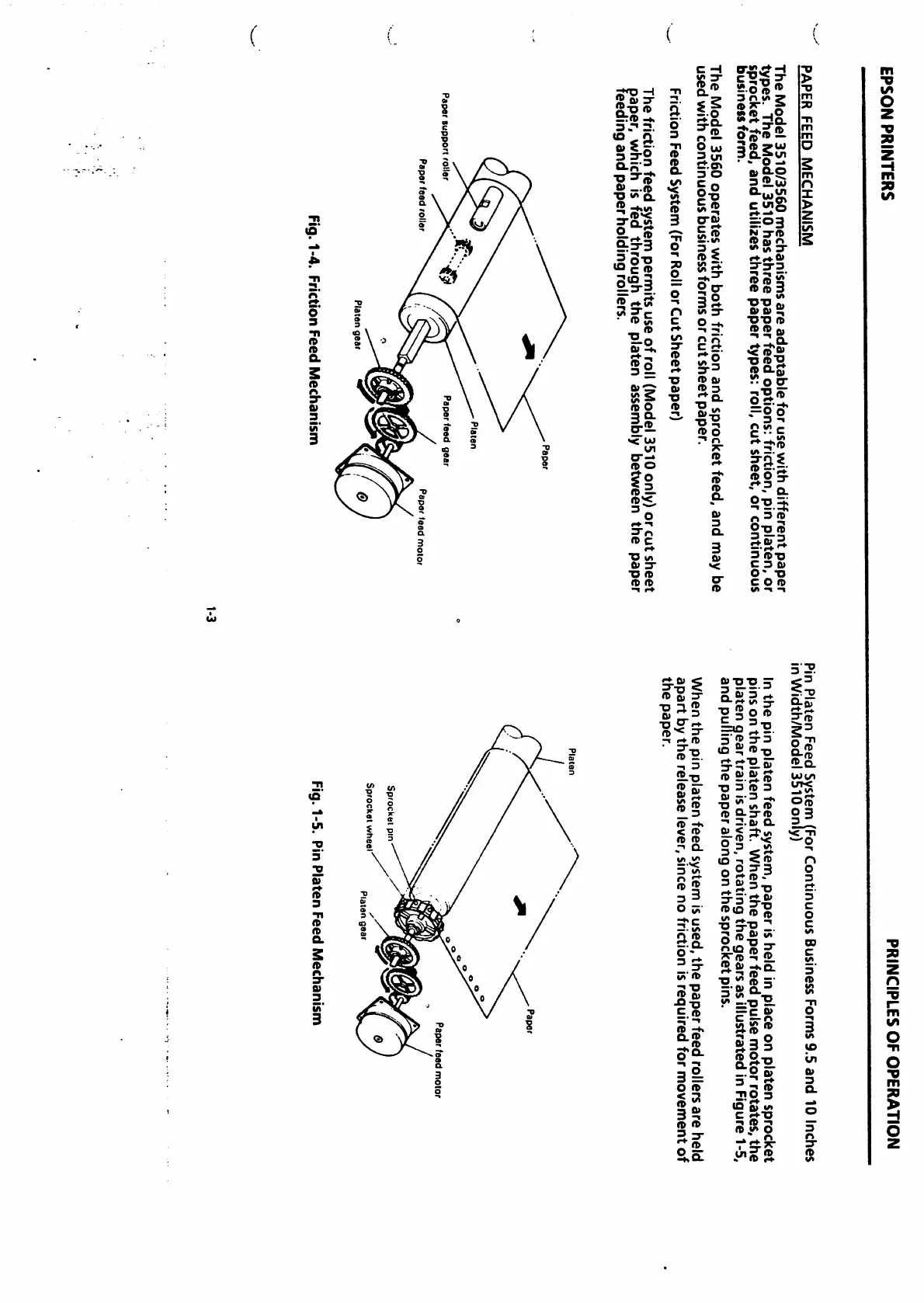

Friction Feed System (For Rollor Cut

Sheet

paper)

The friction

feed

system permits use of roll (Model 3510 only) or

cut

sheet

paper, which is fed

through

the

platen

assembly

between

the

paper

feeding

and

paper

holding rollers.

Paper

support

roller

Paper

feed

roller

Platen

gear

Platen

Paper

feed

gear

Fig.1-4. Friction Feed Mechanism

Paper

tead

motor

1-3

PRINCIPLES

OF

OPERATION

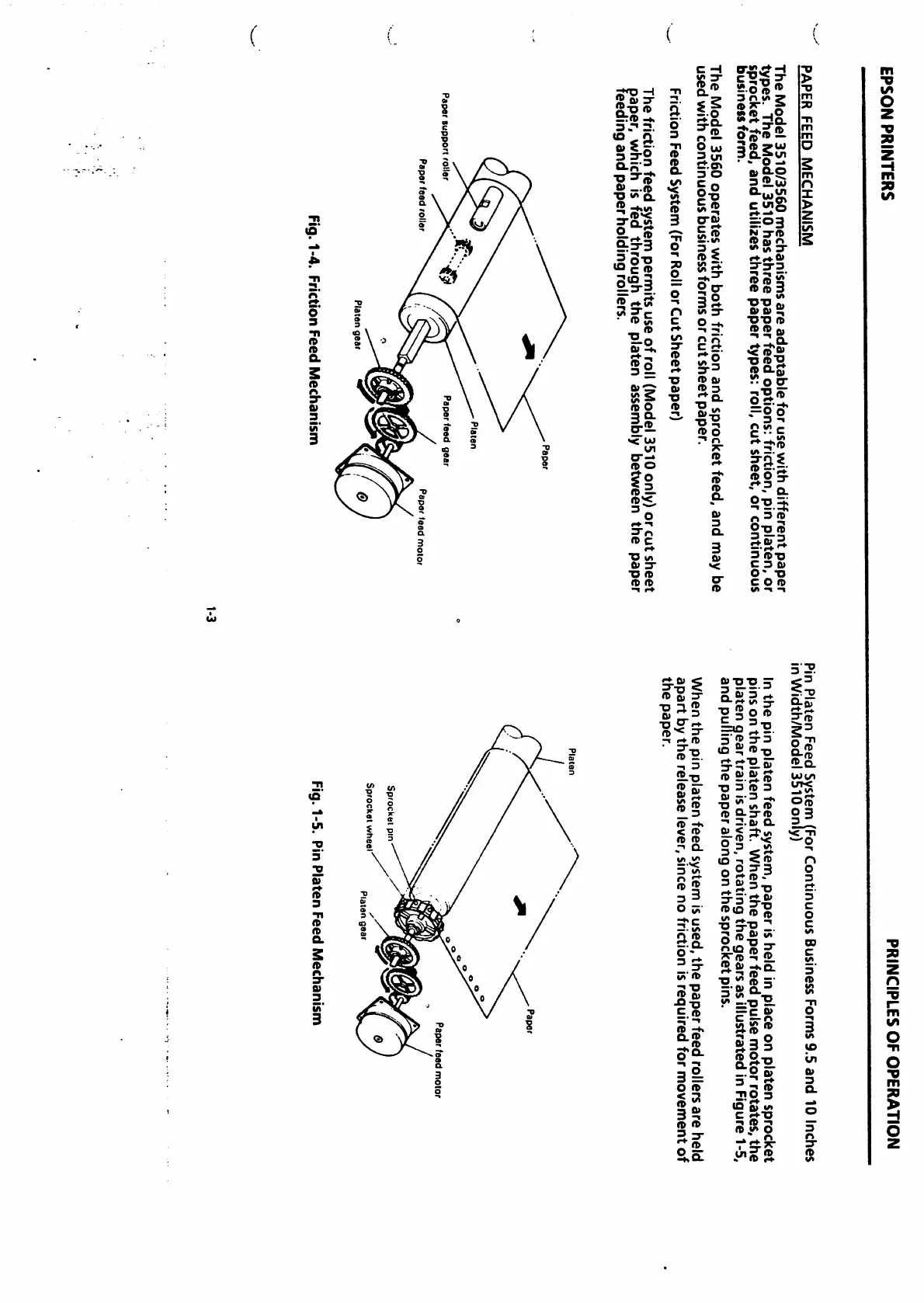

Pin Platen Feed System (For Continuous Business Forms 9.5

and

10 Inches

in Width/Model 3510 only)

In

the

pin

platen

feed

system,

paper

is

held

in place

on

platen

sprocket

pins

on

the

platen

shaft.

When

the

paper

feed

pulse

motor

rotates,

the

platen

aear

train

is

driven,

rotating

the

gears

as

illustrated

in

Figure

1-5,

and

pulling

the

paper

along

on

the

sprocket

pins.

When

the

pin

platen

feed

system is

used,

the

paper

feed

rollers

are

held

apart

by

the

release lever, since no friction is required

for

movement

of

tne

paper.

Platen

Sprocket

ptn

Sprocket

wheel

Platen

gear

Paper

feed

motor

Fig. 1-5. Pin Platen Feed Mechanism

Loading...

Loading...