100i / 200i / 300i / 400i

92 OPERATION Manual PN: 0560956430

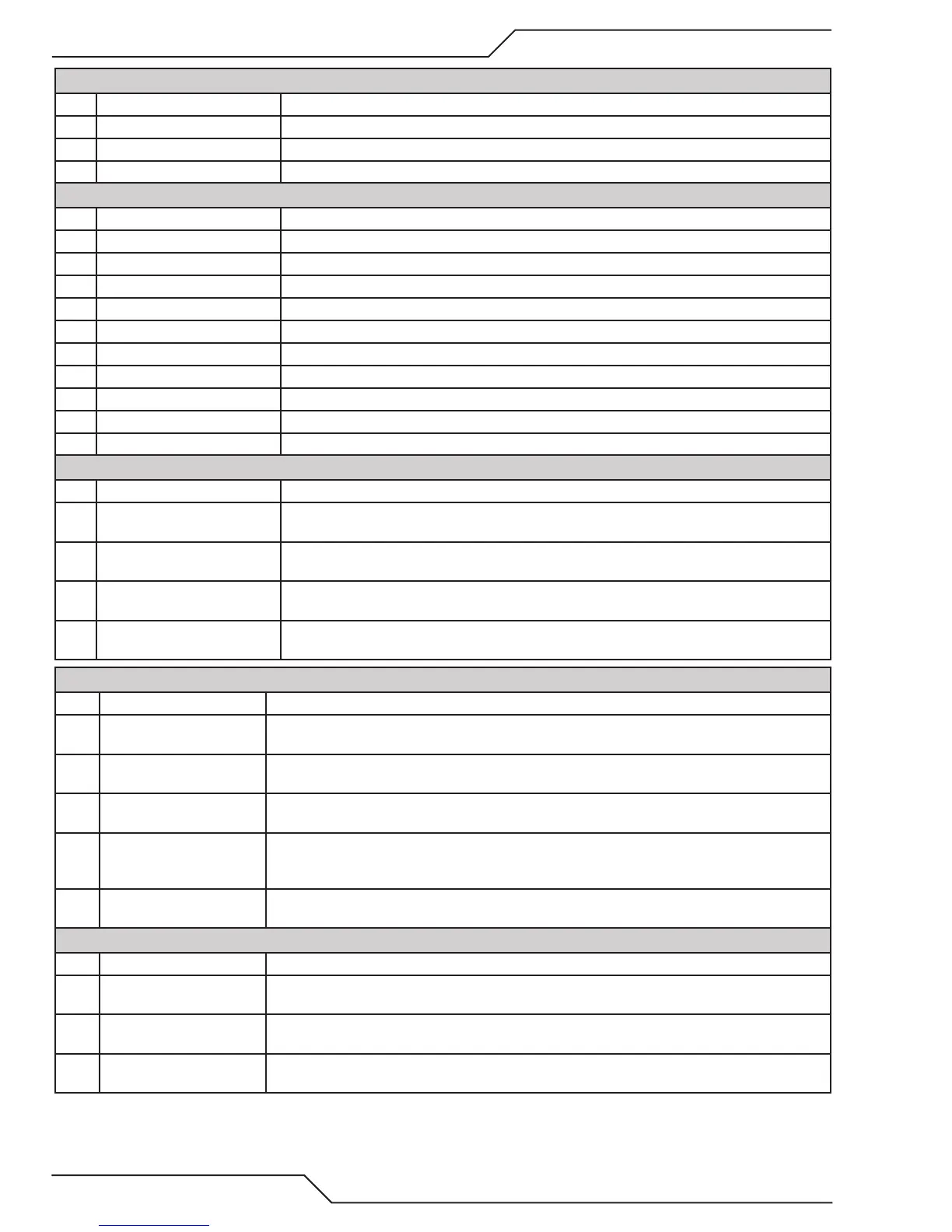

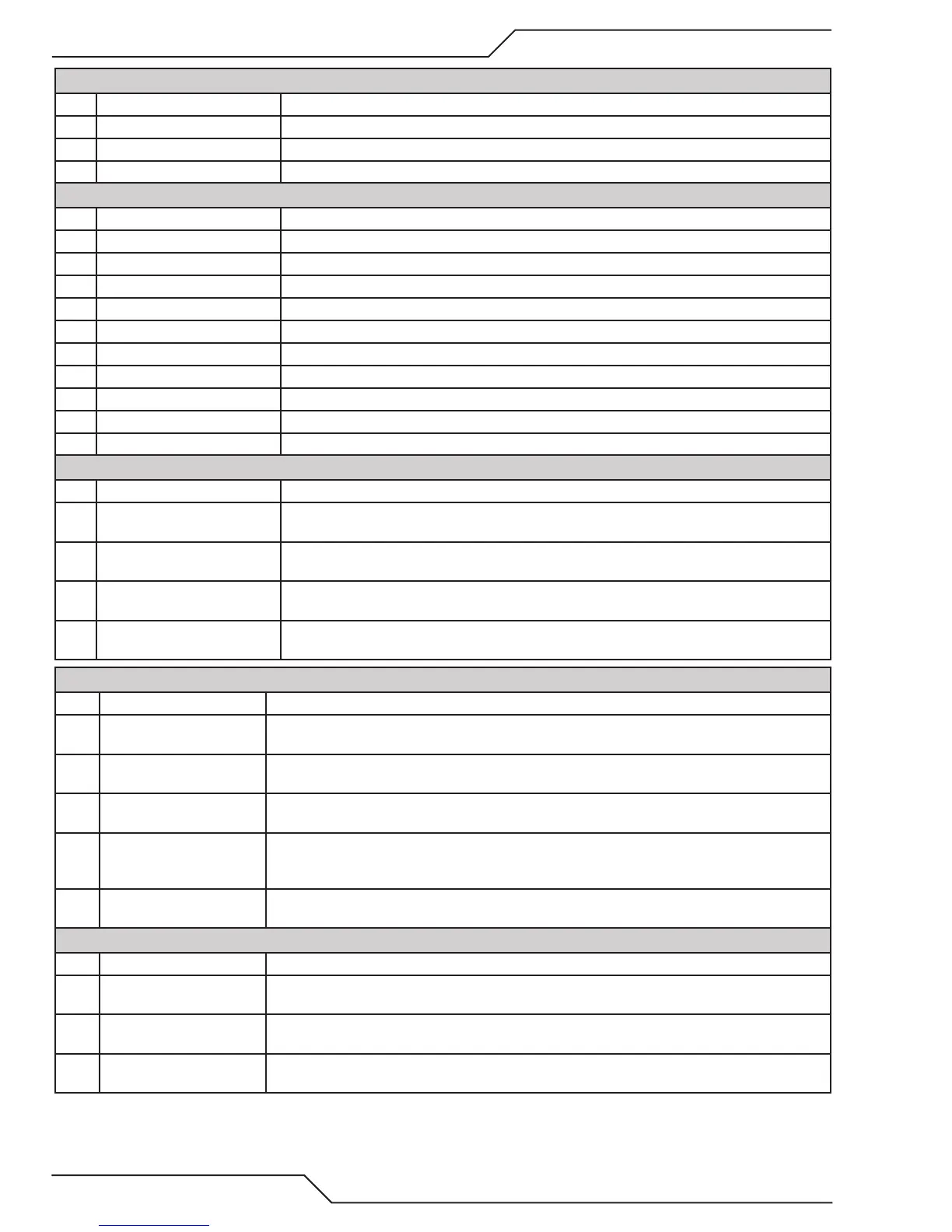

Group 3 - Inlet Pressure Faults

3-1 Plasma Gas High (>145 PSI) Reduce pressure from gas supply; defective pressure sensor (PS4).

3-2 Pilot Gas High (>145 PSI) Reduce pressure from gas supply; defective pressure sensor (PS3).

3-3 Shield Gas High (>145 PSI) Reduce pressure from gas supply; defective pressure sensor (PS1).

3-4 Shield H2O High (>145 PSI) Reduce pressure from gas supply; defective pressure sensor (PS2).

Group 4 - Proportional Valves & Solenoids Electrical Faults

4-1 Plasma High (V5) shorted Check for shorted wire harness; Replace valve

4-2 Plasma Low (V4) shorted Check for shorted wire harness; Replace valve

4-3 Pilot (V3) shorted Check for shorted wire harness; Replace valve

4-4 Shield Gas (V1) shorted Check for shorted wire harness; Replace valve

4-5 Shield H2O (V2) shorted Check for shorted wire harness; Replace valve

4-6 Vent (SOL2) shorted Check for shorted wire harness; Replace valve

4-7 Cut (SOL3) shorted Check for shorted wire harness; Replace valve

4-8 Mark (SOL1) shorted Check for shorted wire harness; Replace valve

4-9 Vent (SOL2) open Check for open connection; Replace valve.

4-10 Cut (SOL3) open Check for open connection; Replace valve.

4-11 Mark (SOL1) open Check for open connection; Replace valve.

Group 5 - Plasma High Proportional Valve (V5)

5-1 Valve open Check for open connection; Replace valve.

5-2 Gas Control Unit inlet Supply

pressure low

Raise plasma inlet pressure; check for Gas Selection Console valve not open; restriction in gas

supply / hoses.

5-3 Outlet pressure too low Valve full open. Leak in plasma hose to torch; defective control valve (V5); defective pressure

sensor (PS6); Gas Control Unit Control PCB

5-4 Outlet pressure low Tracking error Leak in plasma hose to torch; defective control valve (V5); defective pressure sen-

sor (PS6); Gas Control Unit Control PCB

5-5 Outlet pressure too high. Valve at minimun setting. Restriction in plasma hose, torch, Gas Control Unit manifold; defective

control valve (V5); defective pressure sensor (PS6); Gas Control Unit Control PCB

Group 6 - Plasma Low Proportional Valve (V4)

6-1 Valve open Check for open connection; Replace valve.

6-2 Gas Control Unit inlet Sup-

ply pressure low

Raise plasma inlet pressure; check for Gas Selection Console valve not open; restriction in gas sup-

ply/hoses.

6-3 Outlet pressure too low Valve full open but pressure still too low. Leak in plasma hose to torch; Defective control valve (V4);

Defective pressure sensor (PS6); Gas Control Unit Control PCB

6-4 Outlet pressure low Tracking error. Leak in plasma hose to torch; Defective control valve (V4); Defective pressure sensor

(PS6); Gas Control Unit Control PCB

6-5 Outlet pressure Too high Valve at minimum setting but pressure still too high. Restriction in plasma hose to torch; torch

or Gas Control Unit manifold; Defective control valve (V4); Defective pressure sensor (PS6); Gas

Control Unit Control PCB

6-6 Outlet pressure high Tracking error. Restriction in plasma hose; torch or Gas Control Unit manifold; Defective control

valve (V4); Defective pressure sensor (PS6); Gas Control Unit Control PCB

Group 7 - Pilot Proportional Valve (V3)

7-1 Valve open Check for open connection; Replace valve.

7-2 Gas Control Unit inlet Sup-

ply pressure low

Raise plasma inlet pressure; check for Gas Selection Console valve not open; restriction in gas sup-

ply/hoses.

7-3 Outlet pressure too low Valve full open but pressure still too low. Leak in plasma hose to torch; defective control valve;

defective pressure sensor (PS6); Gas Control Unit Control PCB

7-4 Outlet pressure low Tracking error. Leak in plasma hose to torch; defective control valve; defective pressure sensor

(PS6); Gas Control Unit Control PCB

Loading...

Loading...