ESAB CUTMASTER 120

Manual 0-5380 SERVICE

5-5

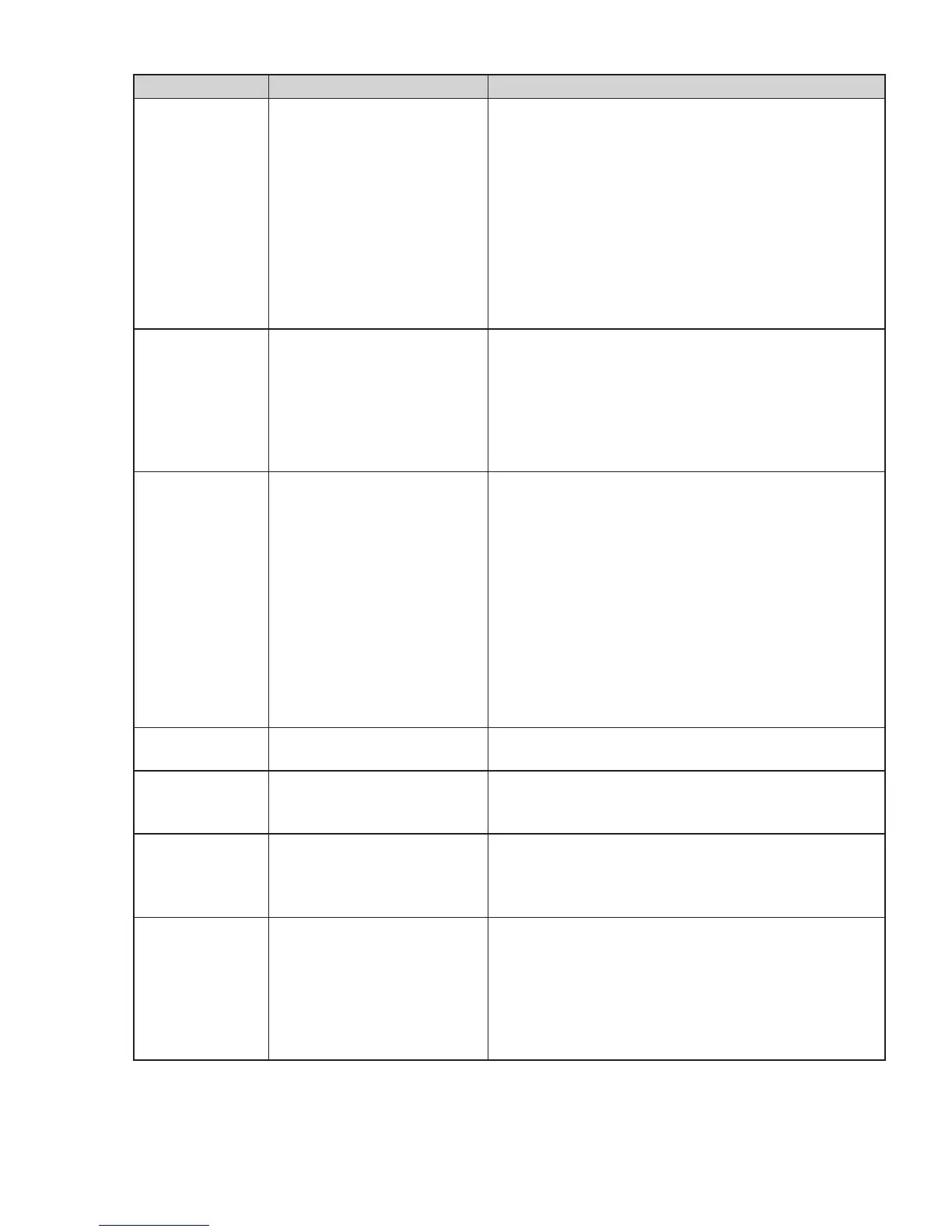

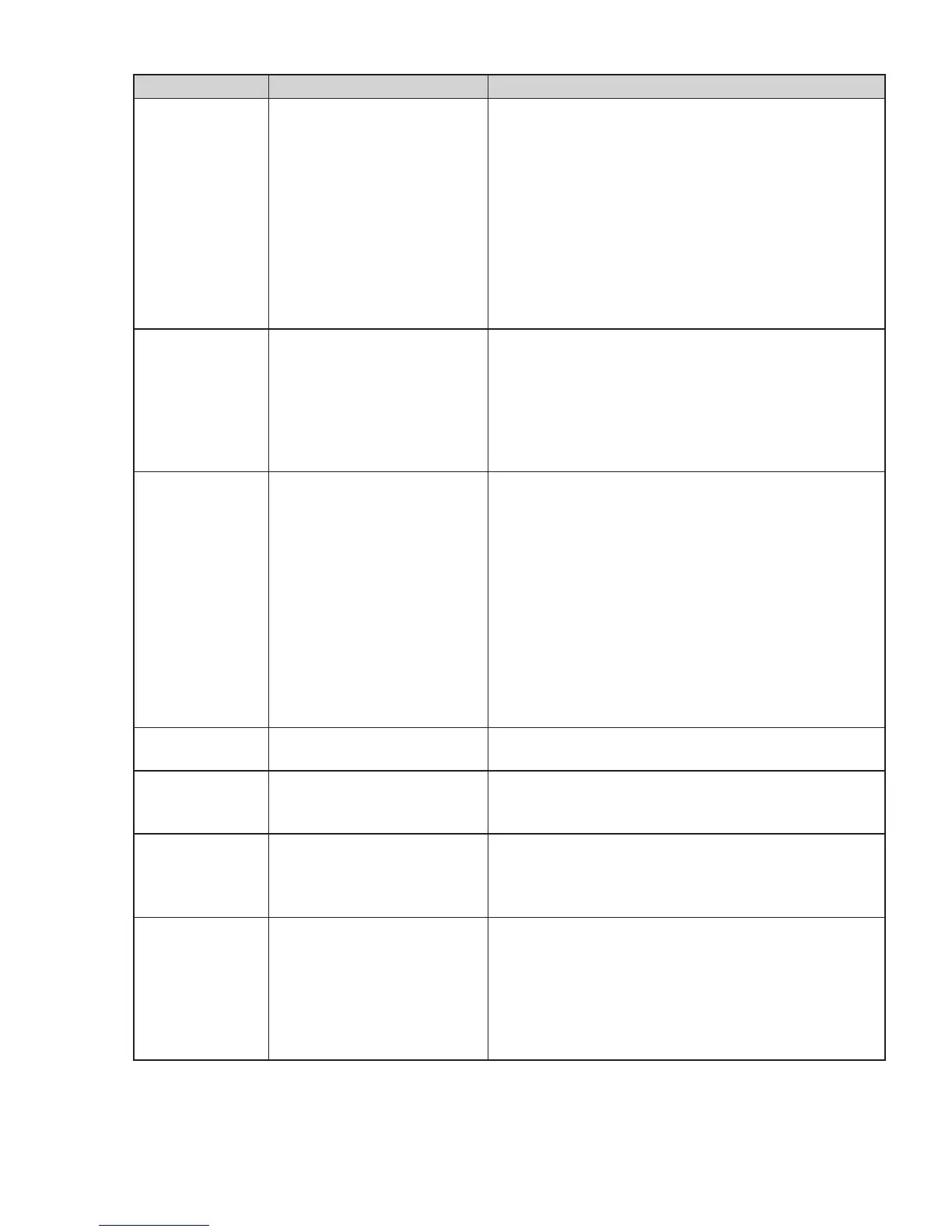

Problem - Symptom Possible Cause Recommended Action

FAULT & 80 PSI

indicators flashing.

Gas flow is cycling ON

and OFF.

1. Torch shield cup is loose.

2. Torch tip, electrode or starter

cartridge missing.

3. Torch starter cartridge is stuck.

4. Open conductor in torch leads.

5. Problem in the torch and leads

switch circuit.

6. Failed components in unit.

1. Tighten shield cup by hand. Do not overtighten.

2. Turn OFF power supply. Remove shield cup. Install missing parts.

3. Turn OFF power supply. Bleed down system pressure. Remove

shield cup, tip and starter cartridge. Check starter cartridge lower

end fitting for free movement. Replace if fitting does not move freely.

4. Replace torch and leads or return to authorized service center for

repair or replacement.

5. Replace torch and leads or return to authorized service center for

repair or replacement.

6. Return to authorized service center for repair or replacement.

Nothing happens when

torch switch or remote

switch is closed (Or

CNC START signal is

active) No gas flow,

DC LED OFF.

1. Problem in the torch and leads

switch circuit (Remote pendant

switch circuit).

2. CNC Controller device not providing

Start signal.

3. Failed components in unit.

1. Take Torch and Leads (Remote Pendant) to Authorized Repair

Facility.

2. Contact Controller manufacturer.

3. Return to authorized service center for repair or replacement.

FAULT and 85 PSI

indicators flashing.

1. Upper O-Ring on torch head is in

wrong position.

2. Torch starter cartridge is stuck.

3. Worn or faulty torch parts.

4. Shorted Torch.

5. Temporary Short indicated by 5

blinks per second.

6. Power Supply Failure (Standard

rate of blinking)

1. Remove shield cup from torch; check upper O-Ring position;

correct if necessary.

2. Turn OFF power supply. Bleed down system pressure. Remove

shield cup, tip and starter cartridge. Check starter cartridge lower

end fitting for free movement. Replace if fitting does not move freely.

3. Inspect torch consumable parts. Replace if necessary.

4. Replace torch and leads or return to an authorized service center

for repair.

5. Release torch switch and reactivate.

6. Return to authorized service center for repair or replacement.

No Fault lights ON, no

arc in torch.

1. Failed components in unit. 1. Return to an authorized service center for repair.

Fault and 90 PSI

indicators flashing

1. Internal Error 1. Turn the ON / OFF switch OFF then back ON again. If that does not

clear the fault, return to an authorized service center for repair.

Pilot arc is ON but

cutting arc will not

establish

1. Work cable not connected to work

piece.

2. Work cable/connector broken.

3. Failed components in unit.

1. Connect work cable.

2. Replace work cable.

3. Return to an authorized service center for repair.

Torch cutting is

diminished

1. Incorrect current setting.

2. Worn torch consumables.

3. Poor work cable connection to

work piece.

4. Torch being moved too fast.

5. Excessive oil or water in torch.

6. Failed components in unit.

1. Check and adjust to proper setting.

2. Check torch consumables and replace as needed.

3. Check the connection of the Work Lead to the work piece.

4. Reduce cutting speed.

5. Refer to "Check air quality" in section 3 Torch.

6. Return to an authorized service center for repair.

Loading...

Loading...