35

SECTION 5 MAINTENANCE

5. Once the Pilot Arc is established, if the torch is close enough to the work, and the work piece is grounded,

Main Arc will transfer to work. Once main arc is established, which will be veried by sensing the work

current through HS2 (work current greater than 5A), power supply will send the Arc ON signal to CNC/

Process Controller via CAN and begins to ramp up current in accordance with the TDF le or the internal

matrix.

6. After a cut is nished or stop signal is sent from the CNC/Process Controller, power supply ramps down

the current according to TDF/SDP le, the fan stays ON and the K1 contactor remains closed for 5 min-

utes. If another start signal is sent prior to the 5 minutes time out, as the bus lter capacitor voltage will

be at 360 VDC, power supply will not go through the soft start sequence.

7. After the 5 minutes timer timed out, main fan turns o and K1 opens. Now, if a start signal is sent, the

EPP-362 will perform the sequence of operations - steps 1 through 6.

In case of MARKING, CNC/Process Controller will send the marking mode ON signal to power source via CAN

Communication. Power source then closes RB1-5 relay to send 115 VAC to RAS box where the marking mode VDR

ratio is selected for proper operation. The rest of operation is same as mentioned in steps 1 through 7 from the

plasma unit.

COOLANT

CIRCULATOR

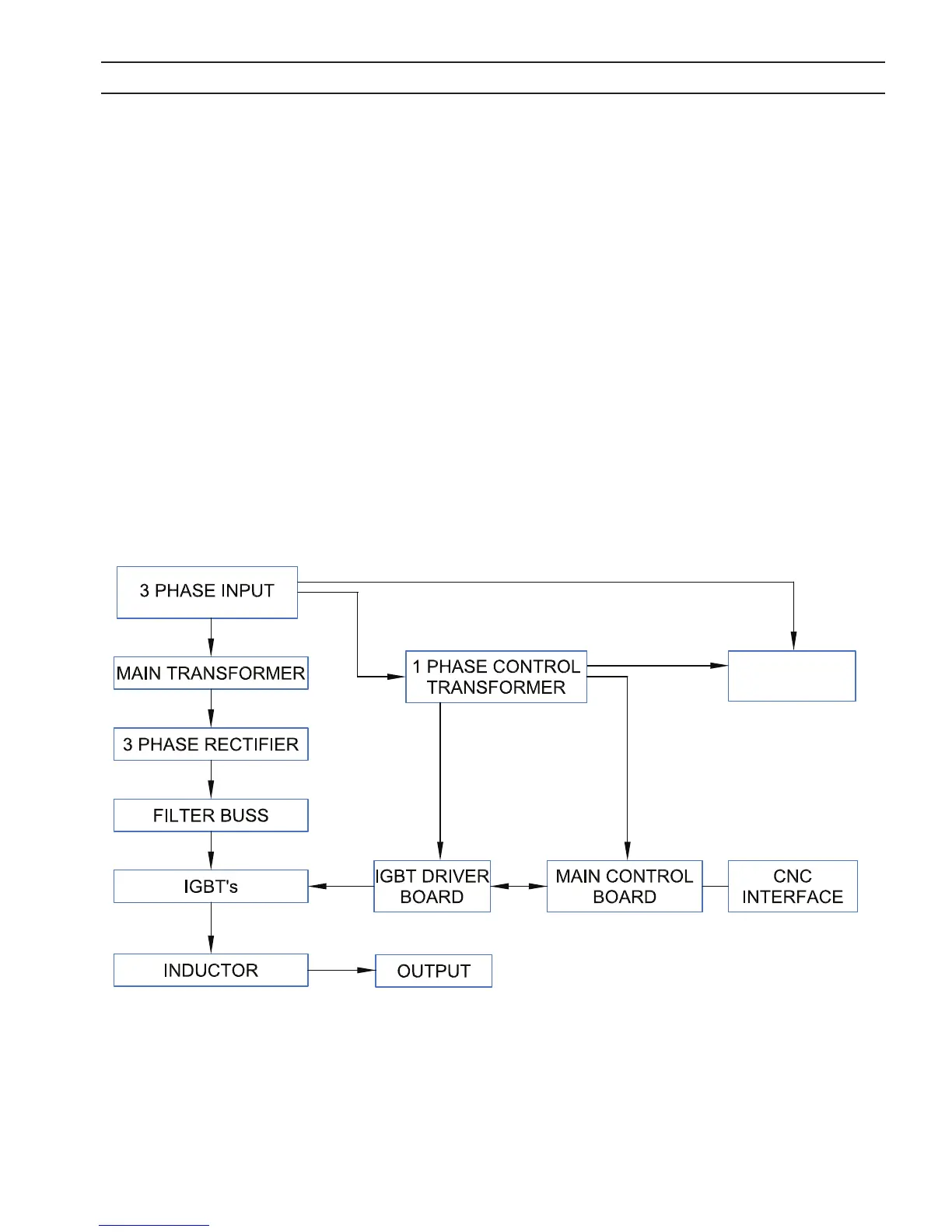

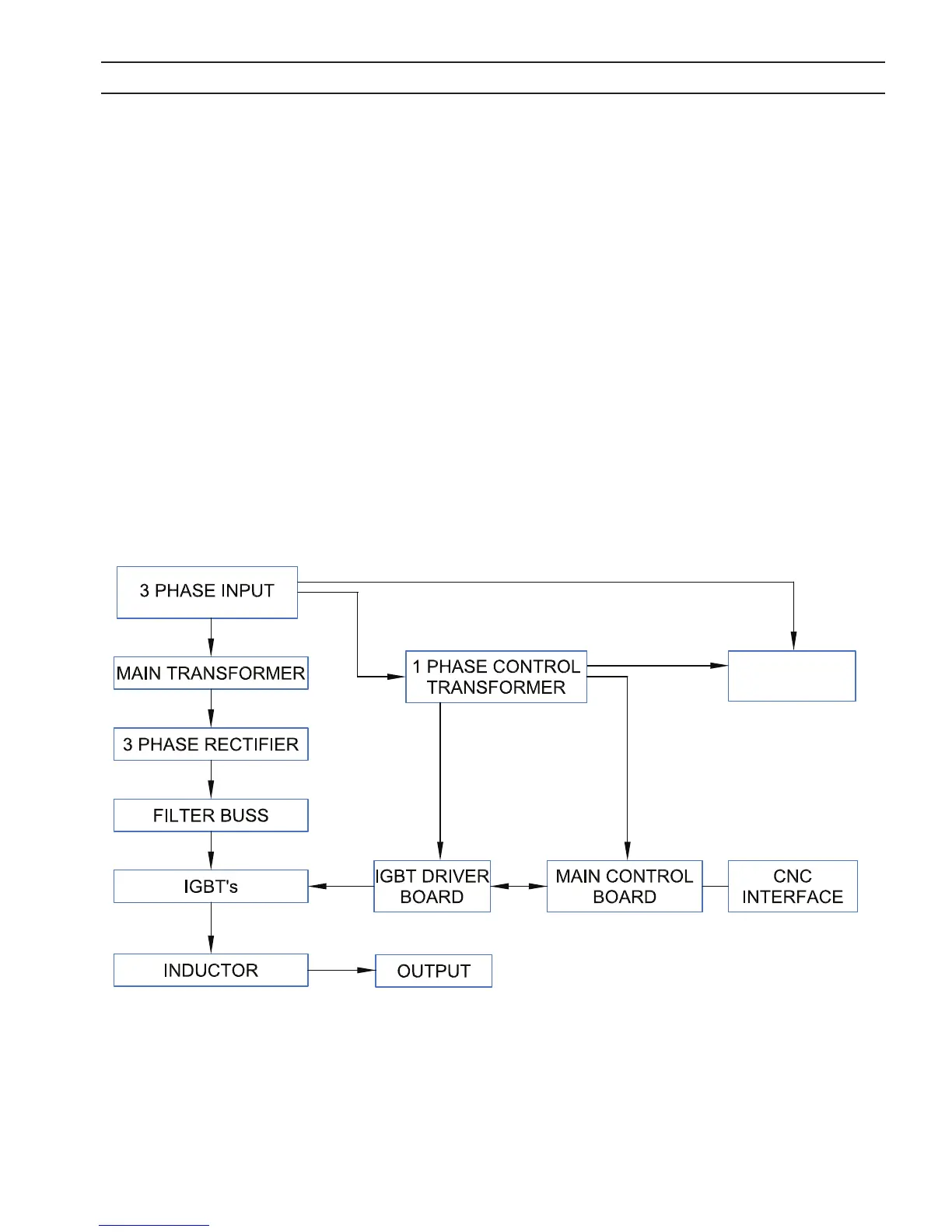

Machine Operation Flow Diagram

Loading...

Loading...