42

SECTION 6 TROUBLESHOOTING

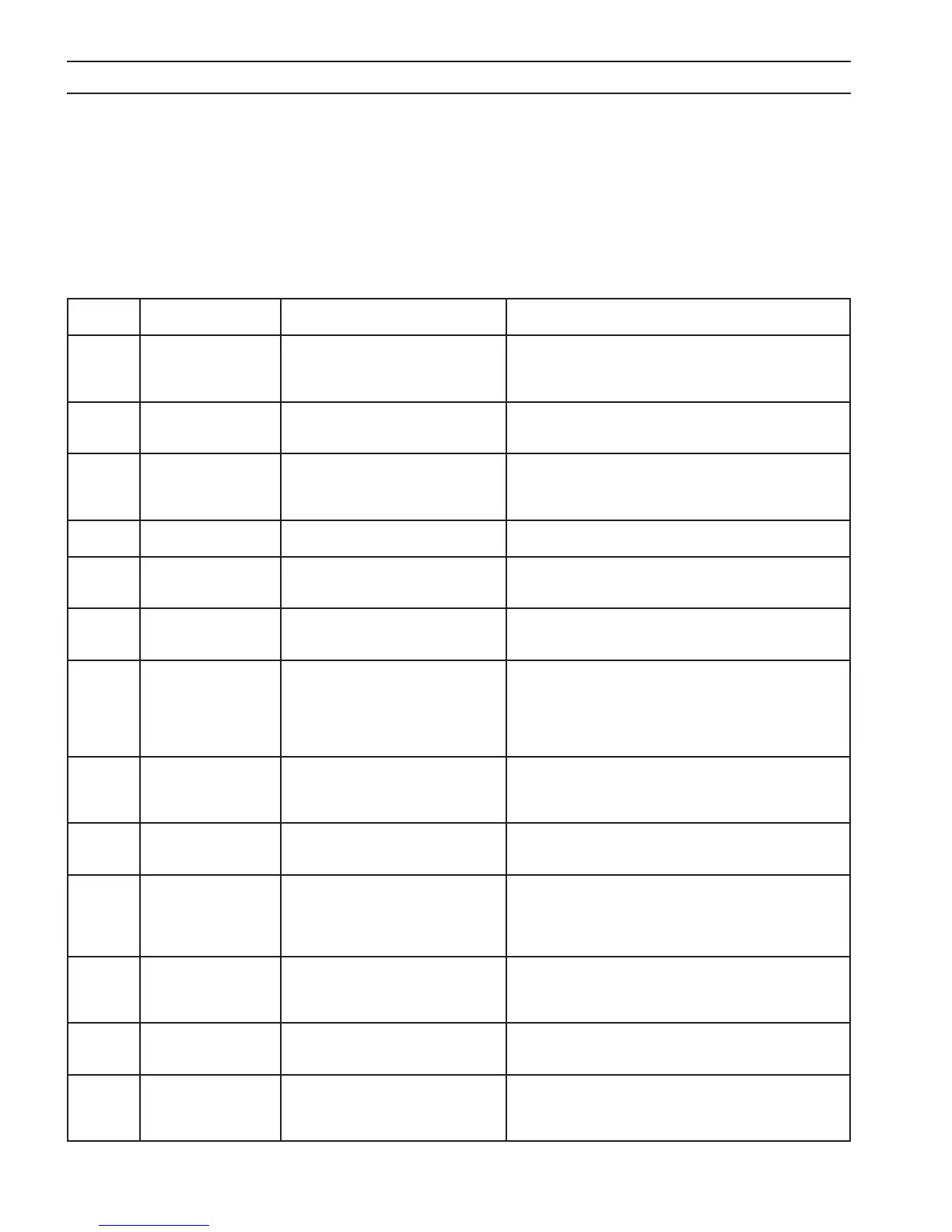

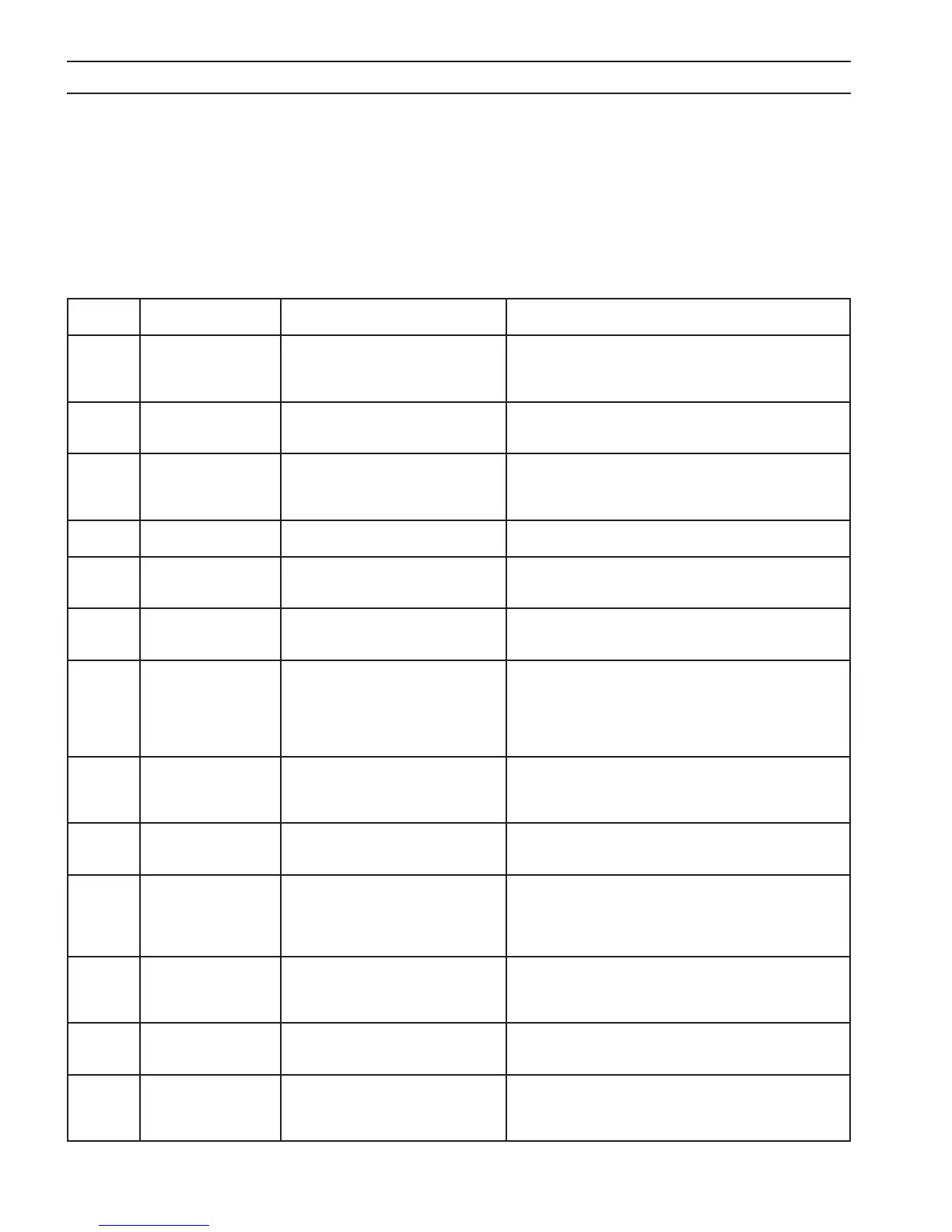

6.2 Help Codes

When fault light is in either one of the above-mentioned states, check the CNC/Process Controller screen for the

complete description of the error.

The list of errors with detail description for EPP 202 are shown in the table below

Error code

displayed

Error Name Description Explanation

1 LINE VOLT, IDLE Supply Line Voltage exceeded or

dropped below + or - 15% of rated input

when machine is in Idle mode

In idle state, control board’s main micro monitors the bus

voltage. If the bus voltage doesn’t satisfy the threshold limits,

it might be due to abnormal line voltages. Check input line volt-

ages with meter.

2 LINE VOLT,

CUTTING

Supply Line Voltage exceeded or

dropped below + or - 20% of rated input

while cutting

During cutting bus voltage failed to satisfy the threshold limits,

check the input line voltages with meter.

3 CONTROL BIAS Control Transformer not supplying

proper voltage to control board or the

+24 and +/-15 volt bias supplies are not

balanced

Bias supply voltages failed to satisfy the threshold limits. Check

the control transformer voltages on TB3 if they record as per

documentation then replace the control board.

4 THERMAL SWITCH OPEN Thermal switch circuit is open Either diode bridge or IGBT module is overheated. Please check

the coolant ow and main fan operation.

5 START ON POWER UP START signal from the CNC is available

before the power source is powered.

There was a start signal issued from the CNC/Process control-

ler during the start-up of power source. Please check the start

signal and CAN connection.

6 FAIL TO FIRE Failed to re/ ignition did not take place

during the allowed time for arc ignition.

After start signal is issued from the CNC/Process Controller,

power source failed to re. Check the HF relay, consumables, PA

IGBT, and height of torch from the plate.

8 TORCH ERROR Torch error/Electrode current was pres-

ent before the PWM was enabled.

If there is electrode current present before the start signal is

issued or PWM engage signal issued, there might be a short in

the torch cable or electrode and nozzle are touching each other.

Check the torch cable, consumables, and also check the jumper

on J1(RAS) L and J pins inside the RAS box which will simulate

regular and blow-back torch.

9 ARC VOLT. OVER 40V,

IDLE

Arc voltage is greater than 40V in Idle

mode.

There is an output voltage present in the idle state before start

signal issued. This could be due to shorted IGBTs or bad driver

board. Check the IGBTs, gate pulse connections on the driver

board.

11 OVER CURRENT, IDLE Idle mode current is greater than the

minimum idle current.

Current above the threshold limits detected in the idle state.

Check the hall sensors and their connections to the control

board.

12 SINGLE PHASE OPERA-

TION

One phase of power is missing from the

input

Missing phase detected after start command issued (Cutting or

Marking). After power-up, average bus voltage recorded in the

Idle state and in the Cut state. If the dierence between the two

recorded values is greater than 60V, this error is activated. Check

the input fuses and line voltages with meter.

13 OCV FAILURE Open circuit voltage did not reach 280

volts within 200 msec.

During arc ignition, the output voltage recorded failed to

satisfy the threshold limit with in specied time. Check the

consumables, distance between torch and plate. If this error

activates every time please contact ESAB’s service department.

14 AMBIENT TEMP Ambient temperature exceeded 75° C in

control enclosure.

The thermister on the Control Board (PCB1) has detected tem-

peratures over 75° C. Check for overheated components inside

the control cabinet

15 BUS CHARGER FAULT Bus voltage did not reach 200 volts dur-

ing the allowed time.

Bus voltage failed to reach the threshold limit with in specied

time. Check for faulty input fuse, shorted bus lter capacitor, bus

charger contactor (K2) contacts failure, and bus-charger contac-

tor relay (RB1-1) failure.

Loading...

Loading...