22

SECTION 3 INSTALLATION

Do not connect hoses to a solenoid valve that can be closed when the

pump is operating as damage to pump can result.

3.5 Coolant Connection Procedure

After lling the reservoir, turn ON power source and allow the pump to run with reservoir cap removed in order

to purge air from the radiator, hoses, and torch. Re-check coolant level to ensure reservoir is lled. Replace res-

ervoir cap after purging and checking coolant level. Check for leaks.

CAUTION

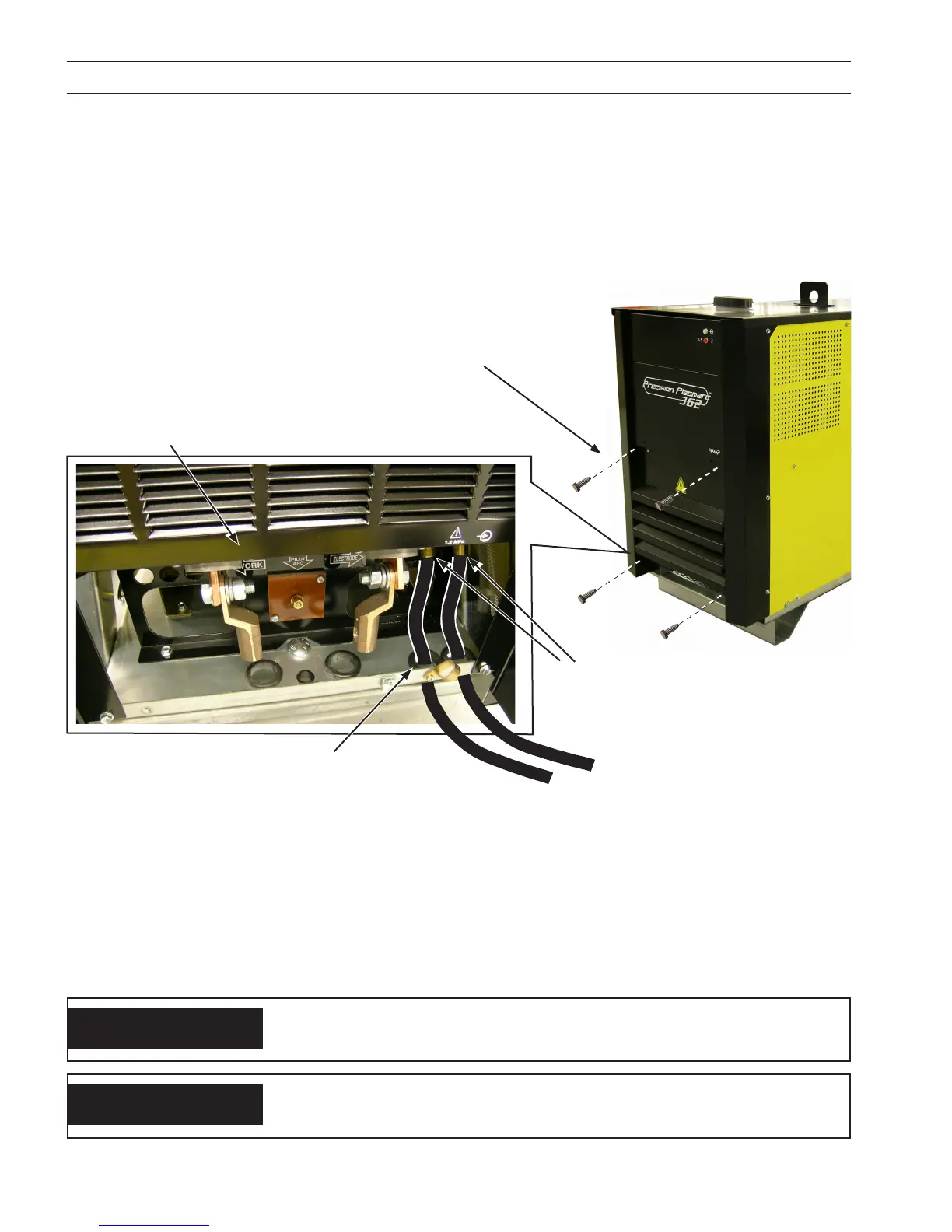

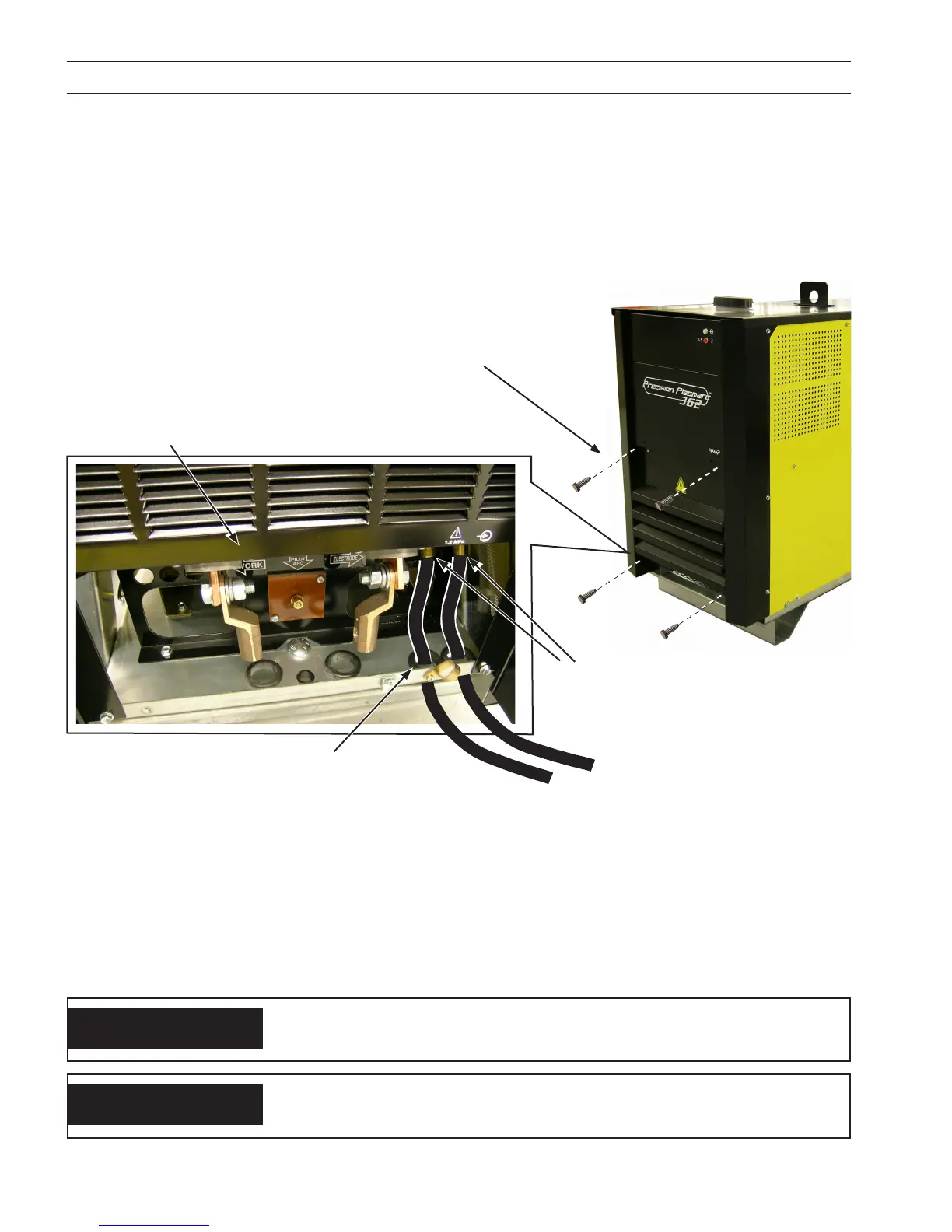

Coolant Connections

Front Access

Panel Opened

1. Open access panel on the lower front of the power source by removing four M6 screws.

2. Thread coolant hoses through the openings at the bottom of the power source immediately behind the

front panel.

3. Connect hoses to designated terminals mounted inside the power source.

4. Close front access panel.

Front Access

Panel Closed

Remove four M6

screws to open

Access Panel

To ease connections, thread cables/

hoses through these 2 access holes

With the torch connected, ll the reservoir with the specially formulated torch coolant (approx 4 gallons). Do not

use regular anti-freeze solutions, such as for an automobile, as the additives will harm the pump and torch. ESAB

P/N 0558004297 is recommended for service down to 12° F (-11° C). ESAB P/N 156F05 is recommended for service

below 12° F (-11° C) to -34° F (-36° C).

Do not allow pump to operate with coolant reservoir empty as per-

manent damage to the pump can result.

CAUTION

Loading...

Loading...